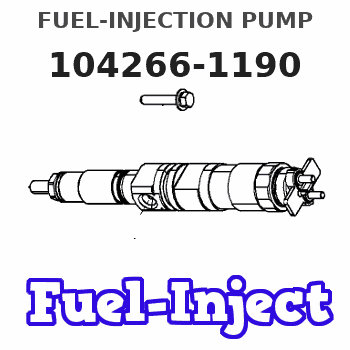

Information fuel-injection pump

BOSCH

9 410 618 375

9410618375

ZEXEL

104266-1190

1042661190

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104266-1190 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 5. | [1] | 141187-3220 | PLUNGER-AND-BARREL ASSY |

| 7. | [2] | 141133-6901 | CAPSULE |

| 7. | [2] | 141133-6901 | CAPSULE |

| 8. | [2] | 141485-1203 | O-RING |

| 8. | [2] | 141485-1203 | O-RING |

| 12. | [1] | 141145-4021 | DELIVERY-VALVE ASSEMBLY |

| 12/1. | [1] | 141146-1800 | SEAT;D.V. |

| 12/2. | [1] | 141138-0500 | FITTING |

| 12/3. | [1] | 141142-9100 | VALVE BODY |

| 12/4. | [1] | 141144-0500 | COMPRESSION SPRING |

| 12/5. | [1] | 141113-3201 | SLOTTED WASHER |

| 12/6. | [1] | 141145-8400 | VALVE BODY |

| 12/7. | [1] | 141112-8701 | COILED SPRING |

| 12/8. | [1] | 141113-2003 | FILLER PIECE |

| 12/9. | [2] | 010235-1620 | HEX-SOCKET-HEAD CAP SCREW |

| 19. | [2] | 016421-0700 | BACKUP RING |

| 20. | [1] | 141118-3002 | O-RING |

| 22. | [6] | 141124-4200 | BLEEDER SCREW |

| 24. | [2] | 016421-0600 | BACKUP RING |

| 25. | [3] | 141485-1002 | O-RING |

| 50. | [1] | 141215-7401 | COMPRESSION SPRING |

| 51. | [1] | 141216-5100 | SLOTTED WASHER |

| 52. | [1] | 141217-8300 | SLOTTED WASHER |

| 53. | [1] | 141218-9000 | GUIDE |

| 55. | [1] | 141220-2900 | LOCKING WASHER |

| 60. | [1] | 141291-1500 | CONTROL RACK |

| 77. | [1] | 141292-5400 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 160. | [1] | 141418-2600 | SET OF NUTS |

| 161. | [1] | 141403-2000 | GASKET |

| 163. | [2] | 373658-1400 | CAPSULE |

| 163. | [2] | 373658-1400 | CAPSULE |

| 164. | [2] | 141403-1800 | GASKET |

| 164. | [2] | 141403-1800 | GASKET |

Include in #2:

104266-1190

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

104266-1190

FUEL-INJECTION PUMP

K 24FW FUEL INJECTION PUMP PF-1SV PF

K 24FW FUEL INJECTION PUMP PF-1SV PF

Information:

Introduction

The following Special Instruction must be used to package a DPF for a core return.

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Note: Whenever the filter is replaced the engine ash model must be reset. Refer to the section below for information on how to reset the ash model.Reset the Engine Ash Model

The engine ash model must be reset whenever the filter is cleaned or replaced. Reseting the ash model places the DPF volume back to the "Clean State". The resetting will allow the regeneration of the DPF to function properly.

Connect to Cat® Electronic Technician (Cat® ET).

Illustration 1 g03345441

Connect to "Engine #1 Aftertreatment Controller".

Illustration 2 g03345627

Select "Service" from the top menu and select "Service Procedures".

Illustration 3 g03345631

From the "Service Procedures" menu, select "DPF Ash Service".

Select "Start".

Illustration 4 g03345633

Select "Ash Service Reset" to start the reset procedure.

Illustration 5 g03345638

You must read the warning and select "Agree" in order to continue.

Illustration 6 g03345643

Choose the correct replacement type of DPF in the menu that appears. The types of replacements for the DPF are the following:

"Field Cleaned" A DPF that has been cleaned and reapplied.

"New" A new DPF replacement

"Remanufactured" A remanufactured DPF replacement.

Illustration 7 g03345648

Illustration 8 g03345650

One the reset is completed, a log of the reset is captured and visible as a new row of information in the DPF Ash Service screen. Resetting the engine ash model does not reset the soot level.

Perform a "Manual DPF Regeneration" with Cat® ET to reset the soot level.Packaging Instructions

Note: The replacement DPF will be packaged with a bag and zip-tie that are used to repackage the DPF that has been removed.

Place the DPF being returned in the enclosed bag and seal the bag with the enclosed zip-tie.

Place the enclosed warning label on the outside of the bag.

Place half of the foam insert on the bottom of the original shipping box with the cut out in the insert facing up.

Place the DPF into the box fitting the DPF into the cut out in the insert.

Place the second half of the foam insert on to of the DPF with the cut out in the insert facing down onto the DPF.

Seal the box with packing tape.Note: If the package weighs over 16 kg (35 lb), additional tape or banding might be required.

Label the package for return shipment.

The following Special Instruction must be used to package a DPF for a core return.

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Note: Whenever the filter is replaced the engine ash model must be reset. Refer to the section below for information on how to reset the ash model.Reset the Engine Ash Model

The engine ash model must be reset whenever the filter is cleaned or replaced. Reseting the ash model places the DPF volume back to the "Clean State". The resetting will allow the regeneration of the DPF to function properly.

Connect to Cat® Electronic Technician (Cat® ET).

Illustration 1 g03345441

Connect to "Engine #1 Aftertreatment Controller".

Illustration 2 g03345627

Select "Service" from the top menu and select "Service Procedures".

Illustration 3 g03345631

From the "Service Procedures" menu, select "DPF Ash Service".

Select "Start".

Illustration 4 g03345633

Select "Ash Service Reset" to start the reset procedure.

Illustration 5 g03345638

You must read the warning and select "Agree" in order to continue.

Illustration 6 g03345643

Choose the correct replacement type of DPF in the menu that appears. The types of replacements for the DPF are the following:

"Field Cleaned" A DPF that has been cleaned and reapplied.

"New" A new DPF replacement

"Remanufactured" A remanufactured DPF replacement.

Illustration 7 g03345648

Illustration 8 g03345650

One the reset is completed, a log of the reset is captured and visible as a new row of information in the DPF Ash Service screen. Resetting the engine ash model does not reset the soot level.

Perform a "Manual DPF Regeneration" with Cat® ET to reset the soot level.Packaging Instructions

Note: The replacement DPF will be packaged with a bag and zip-tie that are used to repackage the DPF that has been removed.

Place the DPF being returned in the enclosed bag and seal the bag with the enclosed zip-tie.

Place the enclosed warning label on the outside of the bag.

Place half of the foam insert on the bottom of the original shipping box with the cut out in the insert facing up.

Place the DPF into the box fitting the DPF into the cut out in the insert.

Place the second half of the foam insert on to of the DPF with the cut out in the insert facing down onto the DPF.

Seal the box with packing tape.Note: If the package weighs over 16 kg (35 lb), additional tape or banding might be required.

Label the package for return shipment.