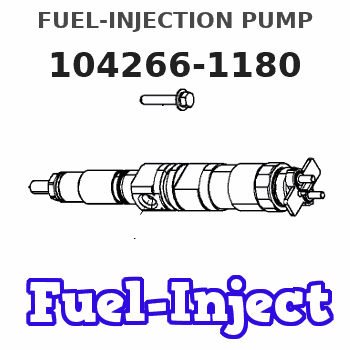

Information fuel-injection pump

BOSCH

9 410 618 343

9410618343

ZEXEL

104266-1180

1042661180

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104266-1180 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 141055-4121 | PUMP HOUSING |

| 5. | [1] | 141187-3220 | PLUNGER-AND-BARREL ASSY |

| 7. | [2] | 141133-6901 | CAPSULE |

| 7. | [2] | 141133-6901 | CAPSULE |

| 8. | [2] | 141485-1203 | O-RING |

| 8. | [2] | 141485-1203 | O-RING |

| 12. | [1] | 141145-4021 | DELIVERY-VALVE ASSEMBLY |

| 12/1. | [1] | 141146-1800 | SEAT;D.V. |

| 12/2. | [1] | 141138-0500 | FITTING |

| 12/3. | [1] | 141142-9100 | VALVE BODY |

| 12/4. | [1] | 141144-0500 | COMPRESSION SPRING |

| 12/5. | [1] | 141113-3201 | SLOTTED WASHER |

| 12/6. | [1] | 141145-8400 | VALVE BODY |

| 12/7. | [1] | 141112-8701 | COILED SPRING |

| 12/8. | [1] | 141113-2003 | FILLER PIECE |

| 12/9. | [2] | 010235-1620 | HEX-SOCKET-HEAD CAP SCREW |

| 19. | [2] | 016421-0700 | BACKUP RING |

| 20. | [1] | 141118-3002 | O-RING |

| 22. | [6] | 141124-4200 | BLEEDER SCREW |

| 24. | [2] | 016421-0600 | BACKUP RING |

| 25. | [3] | 141485-1002 | O-RING |

| 50. | [1] | 141215-7401 | COMPRESSION SPRING |

| 51. | [1] | 141216-5100 | SLOTTED WASHER |

| 52. | [1] | 141217-8300 | SLOTTED WASHER |

| 53. | [1] | 141218-9000 | GUIDE |

| 55. | [1] | 141220-2900 | LOCKING WASHER |

| 60. | [1] | 141291-1500 | CONTROL RACK |

| 68. | [1] | 141456-0700 | CYLINDER |

| 69. | [1] | 026524-2940 | GASKET D28.9&24.3T2 |

| 77. | [1] | 141292-5400 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 160. | [1] | 141418-2600 | SET OF NUTS |

| 161. | [1] | 141403-2000 | GASKET |

| 163. | [2] | 373658-1400 | CAPSULE |

| 163. | [2] | 373658-1400 | CAPSULE |

| 164. | [2] | 141403-1800 | GASKET |

| 164. | [2] | 141403-1800 | GASKET |

| 167. | [1] | 150948-0000 | INLET UNION |

| 168. | [1] | 150949-0100 | EYE BOLT |

| 169. | [2] | 150521-0800 | GASKET |

Include in #1:

101491-9650

as _

Include in #2:

104266-1180

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

104266-1180

FUEL-INJECTION PUMP

K 24FW FUEL INJECTION PUMP PF-1SV PF

K 24FW FUEL INJECTION PUMP PF-1SV PF

Information:

Introduction

Do not perform any procedure that is outlined in the Special Instruction until the entire instruction has been read and understood.Check Valve Torque

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

The check valves that are located within the fuel pressure regulator group are sensitive to assembly torque. In order to eliminate the risk of valve distortion, torque the check valves to 28 3 N m (21 2 lb ft). Refer to Table 1 for the check valve part numbers that required the torque that is listed above.

Table 1

Part Number Description

327-0376 Check Valve Gp

327-4448 Check Valve Gp

281-2725 Check Valve Gp

282-1915 Check Valve Gp

228-7381 Check Valve Gp

327-8044 Check Valve Gp

Do not perform any procedure that is outlined in the Special Instruction until the entire instruction has been read and understood.Check Valve Torque

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat products.Dispose of all fluids according to local regulations and mandates.

The check valves that are located within the fuel pressure regulator group are sensitive to assembly torque. In order to eliminate the risk of valve distortion, torque the check valves to 28 3 N m (21 2 lb ft). Refer to Table 1 for the check valve part numbers that required the torque that is listed above.

Table 1

Part Number Description

327-0376 Check Valve Gp

327-4448 Check Valve Gp

281-2725 Check Valve Gp

282-1915 Check Valve Gp

228-7381 Check Valve Gp

327-8044 Check Valve Gp