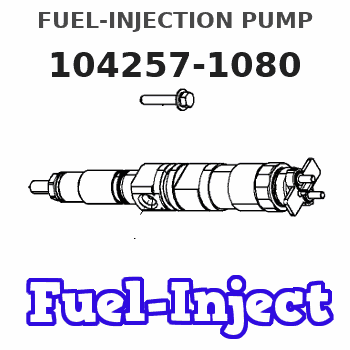

Information fuel-injection pump

BOSCH

9 410 617 608

9410617608

ZEXEL

104257-1080

1042571080

DAIHATSU

E226450620ZZ

e226450620zz

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104257-1080 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 141053-9120 | PUMP HOUSING |

| 5. | [1] | 141185-1420 | PLUNGER-AND-BARREL ASSY |

| 7. | [1] | 141133-5401 | CAPSULE |

| 8. | [1] | 141403-1700 | GASKET |

| 12. | [1] | 141142-1121 | DELIVERY-VALVE ASSEMBLY |

| 12/1. | [1] | 141141-4200 | SEAT;D.V |

| 12/2. | [1] | 141136-9302 | FITTING |

| 12/3. | [1] | 016807-0030 | BALL |

| 12/4. | [1] | 141113-0601 | SLOTTED WASHER |

| 12/5. | [1] | 141112-7100 | COILED SPRING |

| 12/6. | [1] | 141117-9201 | FILLER PIECE |

| 12/7. | [1] | 016804-5030 | BALL |

| 12/8. | [1] | 141113-1500 | SLOTTED WASHER |

| 12/9. | [1] | 141112-8201 | COMPRESSION SPRING |

| 12/10. | [1] | 141117-9302 | FILLER PIECE |

| 12/11. | [2] | 010234-1220 | HEX-SOCKET-HEAD CAP SCREW |

| 20. | [1] | 141482-4902 | O-RING |

| 22. | [4] | 141269-1500 | BLEEDER SCREW |

| 25. | [3] | 141482-5001 | O-RING |

| 50. | [1] | 141215-6301 | COMPRESSION SPRING |

| 51. | [1] | 141216-0100 | SLOTTED WASHER |

| 52. | [1] | 141217-5100 | SLOTTED WASHER |

| 53. | [1] | 141218-8500 | GUIDE |

| 55. | [1] | 026110-6010 | LOCKING WASHER |

| 60. | [1] | 141244-9100 | CONTROL RACK |

| 68. | [1] | 141405-2100 | CAPSULE |

| 69. | [1] | 026522-2740 | GASKET D26.9&22.2T1 |

| 77. | [1] | 141241-8900 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 93. | [1] | 141402-6020 | EYE BOLT |

| 94. | [2] | 141403-1700 | GASKET |

| 160. | [1] | 141418-2200 | SET OF NUTS |

| 161. | [1] | 141403-1400 | GASKET |

| 162. | [1] | 141480-1100 | COVER |

| 172. | [1] | 141402-3320 | EYE BOLT |

| 173. | [2] | 141403-1700 | GASKET |

Cross reference number

Zexel num

Bosch num

Firm num

Name

104257-1080

E226450620ZZ DAIHATSU

FUEL-INJECTION PUMP

K 24EV FUEL INJECTION PUMP PF-1WV PF

K 24EV FUEL INJECTION PUMP PF-1WV PF

Information:

- Generator Monitoring SystemI/O - Input/OutputMMS - Marine Monitoring SystemMMS II - Marine Monitoring System IIPLC - Programmable Logic ControllerThe 203-7811 Engine Monitoring Control Group is the service replacement for the 146-3117 Monitoring Control and the 162-1662 Monitoring Control that are used in MMS. The 203-7811 Engine Monitoring Control Group uses Wonderware as the "Graphic Display Application".The 203-7810 Engine Monitoring Control Group is the optional monitor that is used in the MMS II and the GMS. The 203-7810 Engine Monitoring Control Group uses the RSView as the "Graphic Display Application".When these engine monitoring control groups are used as service replacements in the field, use the procedure that follows to register the software to the user. This procedure can be done when the engine monitoring control group is connected to the PLC. This procedure can also be done when the engine monitoring control group is not connected to the PLC.

Connect a keyboard that is compatible with the PS/2 style of connector. Connect electrical power to the monitor.

Turn on the power.

When you are prompted, accept the license agreement. Press the "Next" button.

Enter the Microsoft Windows NT product identification number. This number is located on the right side of the computer. Press "Next".

When the message indicates that the system could not complete the login, select "OK".

Input "Administrator" for the login username. Input "3600" for the login password.

After a successful login as "Administrator", do one of the items that follow:

Restart the computer.

Close all of the programs and use a different login username.

When the message indicates that the system could not complete the login, select "OK".

Input "Operator" for the login username. Input "password" for the login password.

After a successful login as "Operator", one of the items that follow will occur:

If a 203-7811 Engine Monitoring Control Group is used, the Wonderware I/O Server and the Window Viewer will be started.

If a 203-7810 Engine Monitoring Control Group is used, the RSView Runtime will be started.

Remove the keyboard. The setup is complete.In applications that use Wonderware or RSView, the engine monitoring control group must be connected to the PLC in order for the data to be displayed.After a successful login to the "Operator" account, the computer will automatically start and the computer will start the application in the "Operator" account. The automatic start-up can be bypassed by doing the operations that follow:

Attach a keyboard.

Hold the "shift" key in the down position while the start-up of the computer is initiated.

Connect a keyboard that is compatible with the PS/2 style of connector. Connect electrical power to the monitor.

Turn on the power.

When you are prompted, accept the license agreement. Press the "Next" button.

Enter the Microsoft Windows NT product identification number. This number is located on the right side of the computer. Press "Next".

When the message indicates that the system could not complete the login, select "OK".

Input "Administrator" for the login username. Input "3600" for the login password.

After a successful login as "Administrator", do one of the items that follow:

Restart the computer.

Close all of the programs and use a different login username.

When the message indicates that the system could not complete the login, select "OK".

Input "Operator" for the login username. Input "password" for the login password.

After a successful login as "Operator", one of the items that follow will occur:

If a 203-7811 Engine Monitoring Control Group is used, the Wonderware I/O Server and the Window Viewer will be started.

If a 203-7810 Engine Monitoring Control Group is used, the RSView Runtime will be started.

Remove the keyboard. The setup is complete.In applications that use Wonderware or RSView, the engine monitoring control group must be connected to the PLC in order for the data to be displayed.After a successful login to the "Operator" account, the computer will automatically start and the computer will start the application in the "Operator" account. The automatic start-up can be bypassed by doing the operations that follow:

Attach a keyboard.

Hold the "shift" key in the down position while the start-up of the computer is initiated.