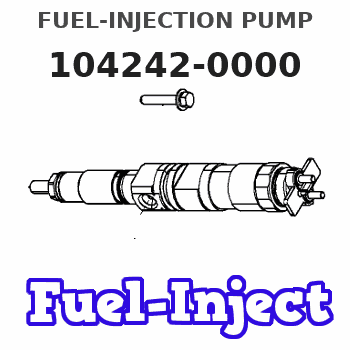

Information fuel-injection pump

BOSCH

9 410 617 413

9410617413

ZEXEL

104242-0000

1042420000

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104242-0000 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | 105033-6030 |

| 11. | NOZZLE |

Scheme ###:

| 5. | [1] | 141185-5121 | PLUNGER-AND-BARREL ASSY |

| 7. | [2] | 141133-4701 | CAPSULE |

| 7. | [2] | 141133-4701 | CAPSULE |

| 8. | [2] | 150934-1100 | GASKET |

| 8. | [2] | 150934-1100 | GASKET |

| 12. | [1] | 141142-9720 | DELIVERY-VALVE ASSEMBLY |

| 20. | [1] | 141482-4901 | O-RING |

| 22. | [4] | 141124-1300 | BLEEDER SCREW |

| 25. | [1] | 141482-5001 | O-RING |

| 40. | [1] | 141200-2620 | TAPPET |

| 44. | [1] | 141212-0500 | BEARING PIN |

| 50. | [1] | 141215-6801 | COMPRESSION SPRING |

| 51. | [1] | 141216-4600 | SLOTTED WASHER |

| 52. | [1] | 141217-7100 | SLOTTED WASHER |

| 56/1. | [1] | 141254-1200 | PLATE T9.7 |

| 56/1. | [1] | 141254-1300 | PLATE T10.0 |

| 56/1. | [1] | 141254-1400 | PLATE T10.3 |

| 56/1. | [1] | 141254-1500 | PLATE T10.6 |

| 56/1. | [1] | 141254-1600 | PLATE T10.9 |

| 56/1. | [1] | 141254-1700 | PLATE T11.2 |

| 56/1. | [1] | 141254-1800 | PLATE T11.5 |

| 56/1. | [1] | 141254-1900 | PLATE T11.8 |

| 60. | [1] | 141244-9901 | CONTROL RACK |

| 77. | [1] | 141241-8400 | CONTROL SLEEVE |

| 93. | [1] | 141402-2100 | EYE BOLT |

| 110. | [1] | 141420-0700 | BLEEDER SCREW |

| 111. | [1] | 141403-1400 | GASKET |

| 152. | [1] | 029901-4010 | CAPSULE |

| 212. | [1] | 141482-2400 | O-RING |

| 220. | [1] | 141260-1900 | CONTROL LEVER |

| 221. | [1] | 141282-0300 | FLAT-HEAD SCREW |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Image1.1.1

Image1.1.2

Image1.1.3

Image1.1.4

Image1.1.5

Image1.1.6

Image1.1.7

Image1.1.8

Image1.1.9

PROCEDURES FOR DPF MODULE REWORK

PROCEDURE ( A ) See Image 1.2.1

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( B ) See Image 1.2.2

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( C ) See Image 1.2.3

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( D ) See Image 1.2.4

Butt weld ring flush to retainer ring on the inlet assembly in 4 spots.

Fillet weld (3 mm weld size) 4 tabs (at 0, 90,180 and 270 degrees.

PROCEDURE ( E ) See Image 1.2.5

Butt weld ring flush to retainer ring on inlet assembly in 4 spots.

Fillet weld 2 pins (at 0 and 180 degree orientation) to outlet side of DPF's 300 mm from each other.

Drill 5/8" holes in the outlet assembly flanges 300 mm from each other.

Place tube flush to the flange inside this hole and weld to outlet assembly.

PROCEDURE ( F ) See Image 1.2.6

Position plates (at 0 and 180 degree orientation) to outlet side of the DPF flange.

Allow plates to extend ( minimum 1/4 inch ) past outer edge. Using slots in plates

weld into place.

PROCEDURE ( G ) See Image 1.2.7

Fillet weld (3 mm weld size) 2 pins (at 0 and 180 degree orientation) to outlet side of DPF 260 mm from each other.

Drill a 5/8" hole in the outlet assembly flange 260 mm from each other 13 mm deep.

Place tube flush to the flange inside this hole and weld to outlet assembly.

PROCEDURE ( H ) See Image 1.2.8

Fillet weld 2 pins (at 0 and 180 degree orientation) to outlet side of both DPF's 300 mm from each other.

Drill 5/8" holes in the outlet assembly flanges 300 mm from each other 13 mm deep.

Place tubes flush to the flange inside this hole and weld to outlet assembly.

PROCEDURE ( I ) See Image 1.2.9 and Image 1.2.10

Remove the clamp and gasket from DPF inlet side.

Mate inlet flange to DPF without gasket or clamp.

Tack weld in place.

Apply a continuous weld to the inlet flange/DPF seam.

Image1.2.1

Image1.2.2

Image1.2.3

Image1.2.4

Image1.2.5

Image1.2.6

Image1.2.7

Image1.2.8

Image1.2.9

Image1.2.10

Filter Module Cross Reference Guide See Image 1.3.1.

Image1.3.1