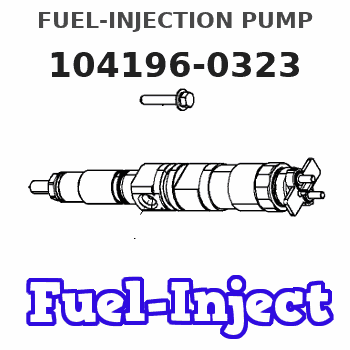

Information fuel-injection pump

BOSCH

9 410 617 168

9410617168

ZEXEL

104196-0323

1041960323

NIIGATA-TEKKOU

11247016A

11247016a

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104196-0323 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 1. | [1] | 141054-5300 | PUMP HOUSING |

| 5. | [1] | 141156-9021 | PLUNGER-AND-BARREL ASSY |

| 7. | [1] | 141106-6500 | CAPSULE |

| 8. | [1] | 029331-2090 | GASKET D17&12.5T1 |

| 12. | [1] | 141140-0620 | DELIVERY-VALVE ASSEMBLY |

| 13. | [1] | 141112-3800 | COMPRESSION SPRING |

| 17. | [1] | 141136-2420 | FITTING |

| 17/1. | [1] | 141136-2400 | FITTING |

| 17/2. | [1] | 141117-5000 | FILLER PIECE |

| 17/3. | [1] | 141405-1000 | CAPSULE |

| 17/4. | [1] | 141405-1100 | BLEEDER SCREW |

| 20. | [1] | 029636-0070 | O-RING |

| 21. | [1] | 141119-3800 | FLANGE BUSHING |

| 22. | [6] | 141124-1000 | BLEEDER SCREW |

| 23. | [1] | 029635-0080 | O-RING |

| 50. | [1] | 141215-2200 | COMPRESSION SPRING |

| 51. | [1] | 141216-1500 | SLOTTED WASHER |

| 52. | [1] | 141217-1600 | SLOTTED WASHER |

| 53. | [1] | 141218-3020 | GUIDE |

| 55. | [1] | 141220-1800 | LOCKING WASHER |

| 60. | [1] | 141243-7600 | CONTROL RACK |

| 77. | [1] | 141292-0800 | CONTROL SLEEVE |

| 81. | [1] | 141245-1500 | POINTER |

| 82/1. | [0] | 141246-0000 | SHIM D66&41.5T0.2 |

| 82/1. | [0] | 141246-0100 | SHIM D66&41.5T0.5 |

| 82/1. | [0] | 141246-0200 | SHIM D66&41.5T1.0 |

| 82/1. | [0] | 141246-0300 | SHIM D66&41.5T3.2 |

| 83. | [2] | 012255-1620 | FLAT-HEAD SCREW |

| 87. | [1] | 029851-0030 | HINGED LID |

| 90. | [2] | 141400-0500 | BUSHING |

| 90. | [2] | 141400-0500 | BUSHING |

| 91. | [2] | 029331-6140 | GASKET D22&16.1T1 |

| 91. | [2] | 029331-6140 | GASKET D22&16.1T1 |

| 204. | [1] | 141010-5100 | COVER |

| 205. | [1] | 141011-0400 | GASKET |

| 206. | [4] | 029001-0280 | BLEEDER SCREW |

| 207. | [1] | 141040-0400 | COVER |

| 208. | [1] | 141041-0100 | GASKET |

| 209. | [2] | 029001-0280 | BLEEDER SCREW |

| 210. | [1] | 029428-0010 | BEARING PIN |

| 230. | [1] | 010212-2020 | HEX-SOCKET-HEAD CAP SCREW |

| 231. | [1] | 026512-1840 | GASKET D17.9&12.2T1.50 |

Include in #1:

106873-2181

as _

Include in #2:

104196-0323

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

104196-0323

9 410 617 168

11247016A NIIGATA-TEKKOU

FUEL-INJECTION PUMP

K 24LB FUEL INJECTION PUMP PF-PC2-5 PF

K 24LB FUEL INJECTION PUMP PF-PC2-5 PF

104196-0323

9 410 617 168

11247017B NIIGATA-TEKKOU

FUEL-INJECTION PUMP

A K 24LB FUEL INJECTION PUMP PF-PC2-5 PF

A K 24LB FUEL INJECTION PUMP PF-PC2-5 PF

Information:

Fluids/Filters Recommendation

Literature InformationThis manual should be stored in the literature holder or in the literature storage area on the machine. Immediately replace this manual if lost, damaged, or unreadable.The information contained in this document is the most current information available for fluid maintenance and service products. Special maintenance and service products may be required for some machine compartments. Refer to the Operation and Maintenance Manual for your machine for the maintenance and service requirements. Read, study, and keep this manual with the product. This manual should be read carefully before using this product for the first time and before performing maintenance.Whenever a question arises regarding your product, or this publication, consult your dealer for the latest available information.SafetyRefer to the Operation and Maintenance Manual for your machine for all safety information. Read and understand the basic safety precautions listed in the Safety Section. In addition to safety precautions, this section identifies the text and locations of warning signs used on the machine.Read and understand the applicable precautions listed in the Maintenance and Operation Sections before operating or performing lubrication, maintenance, and repair on this machine.MaintenanceRefer to the Operation and Maintenance Manual for your machine to determine all maintenance requirements.Proper maintenance and repair are essential to keep the equipment and systems operating correctly. As the owner, you are responsible for the performance of the required maintenance listed in the Owner Manual, Operation and Maintenance Manual, and Service Manual.Maintenance Interval ScheduleUse the Maintenance Interval Schedule in the Operation and Maintenance Manual for your machine to determine servicing intervals. Use the service hour meter to determine servicing intervals. Calendar intervals shown (daily, weekly, monthly, etc.) can be used instead of service hour meter intervals if calendar intervals provide more convenient servicing schedules and approximate the indicated service hour meter reading. Recommended service should always be performed at the interval that occurs first.Under extremely severe, dusty, or wet operating conditions, more frequent lubrication and/or filter changes than is specified in the maintenance intervals chart might be necessary.Following the recommended maintenance intervals reduces the risk of excessive wear and potential failures of components.Aftermarket Products and Warranty

When auxiliary devices, accessories or consumables (filters, oil, additives, catalysts, fuel, etc.) made by other manufacturers are used on Cat products, the Caterpillar warranty is not affected simply because of such use. Failures that result from the installation or usage of other manufacturers auxiliary devices, accessories or consumables, however, are not Caterpillar factory defects and therefore are NOT covered by Caterpillar's warranty.Caterpillar is not in a position to evaluate the many auxiliary devices, accessories or consumables promoted by other manufacturers and their effect on Cat products. Installation or use of such items is at the discretion of the customer who assumes ALL risks for the effects that result from this usage.Furthermore, Caterpillar does not authorize the use of its trade name, trademark, or logo in a manner which implies our endorsement of these aftermarket products.

Literature InformationThis manual should be stored in the literature holder or in the literature storage area on the machine. Immediately replace this manual if lost, damaged, or unreadable.The information contained in this document is the most current information available for fluid maintenance and service products. Special maintenance and service products may be required for some machine compartments. Refer to the Operation and Maintenance Manual for your machine for the maintenance and service requirements. Read, study, and keep this manual with the product. This manual should be read carefully before using this product for the first time and before performing maintenance.Whenever a question arises regarding your product, or this publication, consult your dealer for the latest available information.SafetyRefer to the Operation and Maintenance Manual for your machine for all safety information. Read and understand the basic safety precautions listed in the Safety Section. In addition to safety precautions, this section identifies the text and locations of warning signs used on the machine.Read and understand the applicable precautions listed in the Maintenance and Operation Sections before operating or performing lubrication, maintenance, and repair on this machine.MaintenanceRefer to the Operation and Maintenance Manual for your machine to determine all maintenance requirements.Proper maintenance and repair are essential to keep the equipment and systems operating correctly. As the owner, you are responsible for the performance of the required maintenance listed in the Owner Manual, Operation and Maintenance Manual, and Service Manual.Maintenance Interval ScheduleUse the Maintenance Interval Schedule in the Operation and Maintenance Manual for your machine to determine servicing intervals. Use the service hour meter to determine servicing intervals. Calendar intervals shown (daily, weekly, monthly, etc.) can be used instead of service hour meter intervals if calendar intervals provide more convenient servicing schedules and approximate the indicated service hour meter reading. Recommended service should always be performed at the interval that occurs first.Under extremely severe, dusty, or wet operating conditions, more frequent lubrication and/or filter changes than is specified in the maintenance intervals chart might be necessary.Following the recommended maintenance intervals reduces the risk of excessive wear and potential failures of components.Aftermarket Products and Warranty

When auxiliary devices, accessories or consumables (filters, oil, additives, catalysts, fuel, etc.) made by other manufacturers are used on Cat products, the Caterpillar warranty is not affected simply because of such use. Failures that result from the installation or usage of other manufacturers auxiliary devices, accessories or consumables, however, are not Caterpillar factory defects and therefore are NOT covered by Caterpillar's warranty.Caterpillar is not in a position to evaluate the many auxiliary devices, accessories or consumables promoted by other manufacturers and their effect on Cat products. Installation or use of such items is at the discretion of the customer who assumes ALL risks for the effects that result from this usage.Furthermore, Caterpillar does not authorize the use of its trade name, trademark, or logo in a manner which implies our endorsement of these aftermarket products.

Have questions with 104196-0323?

Group cross 104196-0323 ZEXEL

Niigata-Urawa

Niigata-Tekkou

104196-0323

9 410 617 168

11247016A

FUEL-INJECTION PUMP

104196-0323

9 410 617 168

11247017B

FUEL-INJECTION PUMP