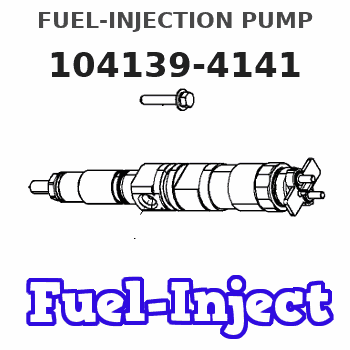

Information fuel-injection pump

BOSCH

9 410 618 333

9410618333

ZEXEL

104139-4141

1041394141

KUBOTA

1G92251012

1g92251012

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

New Fuel Injection Pump Compatible For Kubota V2403 V2203 1G922-51012 104139-4141 9410618333 Excavator Engine Replacement Parts

TBEFQVAW Lightweight design: effectively reduces vehicle load, improves fuel economy, and facilitates installation and handling || Multi specification adaptation: providing multiple flow specifications and models to meet the needs of different displacement engines || Adaptive installation: Standardized interface design, compatible with 95% of mainstream engine models, no need for complex modifications || Anti corrosion coating: The surface of key components is covered with anti-corrosion coating, which is not afraid of humid coastal environments and harsh weather conditions || New Fuel Injection Pump Compatible For Kubota V2403 V2203 1G922-51012 104139-4141 9410618333 Excavator Engine Replacement Parts

TBEFQVAW Lightweight design: effectively reduces vehicle load, improves fuel economy, and facilitates installation and handling || Multi specification adaptation: providing multiple flow specifications and models to meet the needs of different displacement engines || Adaptive installation: Standardized interface design, compatible with 95% of mainstream engine models, no need for complex modifications || Anti corrosion coating: The surface of key components is covered with anti-corrosion coating, which is not afraid of humid coastal environments and harsh weather conditions || New Fuel Injection Pump Compatible For Kubota V2403 V2203 1G922-51012 104139-4141 9410618333 Excavator Engine Replacement Parts

Czomoizc Fuel Injection Pump 1G922-51012 1G852-51010 1G852-51011 Compatible with Kubota V2403 V2203 Engines Bobcat 331 334 335 E42 E45 S130 S150 S185 S175 S510 S530 T110 T140 T190

Czomoizc Part Name: Fuel Injection Pump || Part Number: 1G922-51013,1G922-51012,1G922-51014,1G922-51010,1G852-51012,1G852-51010,1G92251013,1G92251012,1G92251014,1G92251010,1G85251012,1G85251010. || Application Models: Compatible with Kubota V2403 V2203 Engines || Compatible with Bobcat 331 334 335 E42 E45 S130 S150 S185 S175 S510 S530 T110 T140 T190 || Package Includes: 1PC Fuel Injection Pump, 1G922-51012 || This is a aftermarket Fuel Injection Pump , but the size is accurate and has been fully and strictly inspected before leaving the factory.Sold as shown in photos.

Czomoizc Part Name: Fuel Injection Pump || Part Number: 1G922-51013,1G922-51012,1G922-51014,1G922-51010,1G852-51012,1G852-51010,1G92251013,1G92251012,1G92251014,1G92251010,1G85251012,1G85251010. || Application Models: Compatible with Kubota V2403 V2203 Engines || Compatible with Bobcat 331 334 335 E42 E45 S130 S150 S185 S175 S510 S530 T110 T140 T190 || Package Includes: 1PC Fuel Injection Pump, 1G922-51012 || This is a aftermarket Fuel Injection Pump , but the size is accurate and has been fully and strictly inspected before leaving the factory.Sold as shown in photos.

IMIFAFTAbT 1G922-51012 104139-4141 9410618333 Fuel injection pump Fits for Kubota V2403 V2403-T Engine

IMIFAFTAbT Product Name: 1G922-51012 104139-4141 9410618333 Fuel injection pump || Part number: 1G922-51012 104139-4141 9410618333 || Fits for Kubota V2403 V2403-T Engine || 1 PCS Fuel injection pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 1G922-51012 104139-4141 9410618333 Fuel injection pump || Part number: 1G922-51012 104139-4141 9410618333 || Fits for Kubota V2403 V2403-T Engine || 1 PCS Fuel injection pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

You can express buy:

Images:

USD 697.4

[13-May-2025]

USD 432.32

[19-May-2025]

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104139-4141 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105118-8192 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 18.6{190}/22.6{230} |

| 10. | NOZZLE-HOLDER | 105048-2222 |

| 11. | NOZZLE | 105017-3020 |

Scheme ###:

| 5. | [4] | 140163-4420 | PLUNGER-AND-BARREL ASSY |

| 12. | [4] | 140110-6220 | DELIVERY-VALVE ASSEMBLY |

| 13. | [4] | 140112-3400 | COMPRESSION SPRING |

| 16. | [4] | 140115-1400 | GASKET |

| 17. | [4] | 140116-8520 | FITTING |

| 20. | [4] | 140118-0301 | O-RING |

| 30. | [3] | 140131-0521 | FLANGE BUSHING |

| 31. | [1] | 140131-1021 | FLANGE BUSHING |

| 32. | [8] | 140118-0201 | O-RING |

| 32. | [8] | 140118-0201 | O-RING |

| 37. | [8] | 140124-0200 | BLEEDER SCREW |

| 37. | [8] | 140124-0200 | BLEEDER SCREW |

| 40. | [4] | 140200-3120 | TAPPET |

| 44. | [4] | 140212-0300 | BEARING PIN |

| 45. | [1] | 140213-1500 | LOCKING WASHER |

| 50. | [4] | 140215-1900 | COMPRESSION SPRING |

| 51. | [4] | 140216-0800 | SLOTTED WASHER |

| 52. | [4] | 140217-2200 | SLOTTED WASHER |

| 53/1. | [1] | 140253-5001 | PLATE |

| 53/1. | [1] | 140253-5101 | PLATE |

| 53/1. | [1] | 140253-5201 | PLATE |

| 53/1. | [1] | 140253-5301 | PLATE |

| 53/1. | [1] | 140253-5401 | PLATE |

| 53/1. | [1] | 140253-5501 | PLATE |

| 53/1. | [1] | 140253-5601 | PLATE |

| 53/1. | [1] | 140253-5701 | PLATE |

| 53/1. | [1] | 140253-5801 | PLATE |

| 53/1. | [1] | 140253-5901 | PLATE |

| 53/1. | [1] | 140253-6001 | PLATE |

| 53/1. | [1] | 140253-6101 | PLATE |

| 53/1. | [1] | 140253-6201 | PLATE |

| 53/1. | [1] | 140253-6301 | PLATE |

| 53/1. | [1] | 140253-6401 | PLATE |

| 53/1. | [1] | 140253-6501 | PLATE |

| 53/1. | [1] | 140253-6601 | PLATE |

| 53/1. | [1] | 140253-6701 | PLATE |

| 53/1. | [1] | 140253-6801 | PLATE |

| 53/1. | [1] | 140253-6901 | PLATE |

| 53/1. | [1] | 140253-7001 | PLATE |

| 53/1. | [1] | 140253-7101 | PLATE |

| 53/1. | [1] | 140253-7201 | PLATE |

| 53/1. | [1] | 140253-7301 | PLATE |

| 53/1. | [1] | 140253-7401 | PLATE |

| 53/1. | [1] | 140253-7501 | PLATE |

| 53/1. | [1] | 140253-7601 | PLATE |

| 53/1. | [1] | 140253-7701 | PLATE |

| 53/1. | [1] | 140253-7801 | PLATE |

| 53/1. | [1] | 140253-7901 | PLATE |

| 53/1. | [1] | 140253-8001 | PLATE |

| 53/1. | [1] | 140253-8101 | PLATE |

| 53/1. | [1] | 140253-8201 | PLATE |

| 53/1. | [1] | 140253-8301 | PLATE |

| 53/1. | [1] | 140253-8401 | PLATE |

| 53/1. | [1] | 140253-8501 | PLATE |

| 53/1. | [1] | 140253-8601 | PLATE |

| 53/1. | [1] | 140253-8701 | PLATE |

| 53/1. | [1] | 140253-8801 | PLATE |

| 53/1. | [1] | 140253-8901 | PLATE |

| 53/1. | [1] | 140253-9001 | PLATE |

| 53/1. | [1] | 140253-9101 | PLATE |

| 53/1. | [1] | 140253-9201 | PLATE |

| 53/1. | [1] | 140253-9301 | PLATE |

| 53/1. | [1] | 140253-9401 | PLATE |

| 53/1. | [1] | 140296-0000 | PLATE |

| 53/1. | [1] | 140296-0100 | PLATE |

| 53/1. | [1] | 140296-0200 | PLATE |

| 53/1. | [1] | 140296-0300 | PLATE |

| 53/1. | [1] | 140296-0400 | PLATE |

| 53/1. | [1] | 140296-0500 | PLATE |

| 53/1. | [1] | 140296-0600 | PLATE |

| 53/1. | [1] | 140296-0700 | PLATE |

| 53/1. | [1] | 140296-0800 | PLATE |

| 53/1. | [1] | 140296-0900 | PLATE |

| 53/1. | [1] | 140296-1000 | PLATE |

| 53/1. | [1] | 140296-1100 | PLATE |

| 53/1. | [1] | 140296-1200 | PLATE |

| 53/1. | [1] | 140296-1300 | PLATE |

| 53/1. | [1] | 140296-1400 | PLATE |

| 53/1. | [1] | 140296-1500 | PLATE |

| 53/1. | [1] | 140296-1600 | PLATE |

| 53/1. | [1] | 140296-1700 | PLATE |

| 53/1. | [1] | 140296-1800 | PLATE |

| 53/1. | [1] | 140296-1900 | PLATE |

| 53/1. | [1] | 140296-2000 | PLATE |

| 53/1. | [1] | 140296-2100 | PLATE |

| 53/1. | [1] | 140296-2200 | PLATE |

| 53/1. | [1] | 140296-2300 | PLATE |

| 53/1. | [1] | 140296-2400 | PLATE |

| 53/1. | [1] | 140296-2500 | PLATE |

| 53/1. | [1] | 140296-2600 | PLATE |

| 53/1. | [1] | 140296-2700 | PLATE |

| 53/1. | [1] | 140296-2800 | PLATE |

| 53/1. | [1] | 140296-2900 | PLATE |

| 53/1. | [1] | 140296-3000 | PLATE |

| 53/1. | [1] | 140296-3100 | PLATE |

| 53/1. | [1] | 140296-3200 | PLATE |

| 53/1. | [1] | 140296-3300 | PLATE |

| 53/1. | [1] | 140296-3400 | PLATE |

| 53/1. | [1] | 140296-3500 | PLATE |

| 53/1. | [1] | 140296-3600 | PLATE |

| 53/1. | [1] | 140296-3700 | PLATE |

| 53/1. | [1] | 140296-3800 | PLATE |

| 53/1. | [1] | 140296-3900 | PLATE |

| 53/1. | [1] | 140296-4000 | PLATE |

| 53/1. | [1] | 140296-4100 | PLATE |

| 53/1. | [1] | 140296-4200 | PLATE |

| 53/1. | [1] | 140296-4300 | PLATE |

| 60. | [1] | 140243-5720 | CONTROL RACK |

| 77. | [4] | 140241-4200 | CONTROL SLEEVE |

| 93. | [1] | 140402-2500 | EYE BOLT |

| 94. | [2] | 026512-1540 | GASKET D15.4&12.2T1.50 |

| 112. | [2] | 140420-1400 | BLEEDER SCREW |

| 112. | [2] | 140420-1400 | BLEEDER SCREW |

| 113. | [2] | 026508-1240 | GASKET D11.9&8.2T1 |

| 113. | [2] | 026508-1240 | GASKET D11.9&8.2T1 |

| 170. | [2] | 140445-0320 | PLATE |

Include in #2:

104139-4141

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

1G92251012 KUBOTA

FUEL-INJECTION PUMP

* K 23AD FUEL INJECTION PUMP PFR-4KX PFR

* K 23AD FUEL INJECTION PUMP PFR-4KX PFR

1G92251013 KUBOTA

FUEL-INJECTION PUMP

A * K 23AD FUEL INJECTION PUMP PFR-4KX PFR

A * K 23AD FUEL INJECTION PUMP PFR-4KX PFR

Information:

Recommended Procedure1. Air in Fuel System With air in the fuel system the engine will normally be difficult to start, run rough and release a large amount of white smoke. Remove the air from the fuel system by either loosening the cap on the tee at the fuel filter or by loosening the fuel line nuts one at a time at the cylinder heads. Turn the engine with the starter until the fuel flow at this connection is free of air. If air is not removed in this way, put 5 psi (0,35 kg/cm2) [CAUTION do not use more than 8 psi (0,56 kg/cm2)] of air pressure to the fuel tank and check for leaks at connections between the fuel tank and the fuel transfer pump. If there are no leaks at the connections, remove the fuel supply line from the tank and connect it to an outside fuel supply. If this corrects the problem the suction line (standpipe) inside the fuel tank has a leak.2. Valve Adjustment Not Correct Check and make necessary adjustments as per Testing and Adjusting section of the Service Manual. Intake valve adjustment is .015 in. (0,38 mm) and exhaust valve adjustment is .025 in. (0,64 mm).3. Fuel Injection Timing Not Correct Check and make necessary adjustments as per Testing and Adjusting section of the Service Manual.4. Automatic Timing Advance Does Not Operate Correctly Check with engine warm. Use the 1P3500 Timing Light Group. Special Instruction (SMHS6964) gives the test procedure. If the timing light is not available, make rapid "acceleration" (increase in speed) from low idle to high idle. Engine must have smooth acceleration. A timing advance that does not operate correctly can cause delays of the engine acceleration at some rpm before high idle, or possibly cause the engine to run rough and have exhaust noise (backfire) during acceleration. This condition is difficult to find if engine acceleration is slow or at a constant engine rpm.5. Bad Fuel Nozzle(s) Find a bad nozzle by running engine at the rpm range where it runs rough. Loosen the fuel line nut at the cylinder head enough to stop fuel supply to that cylinder. Each cylinder must be checked this way. If a cylinder is found where loosening of the nut makes no difference in the rough running, test the nozzle for that cylinder. To test a nozzle, remove the nozzle from the engine and test as per Testing and Adjusting section of the Service Manual.6. Valve Leakage; Wear or Damage to Pistons and/or Piston Rings; Wear or Damage to Cylinder Walls Check with the cylinder leakage tester. If leakage is over specification and leaking is heard at the air inlet to the engine (intake valve leaks), exhaust manifold (exhaust valve leaks), or at the oil filler opening (leaking past piston rings). Special Instruction (GMG00694) gives the test procedure.7. Cylinder Head Gasket Leakage Check with the cylinder leakage tester. If leakage is higher than specification, check at the fuel nozzle hole of the