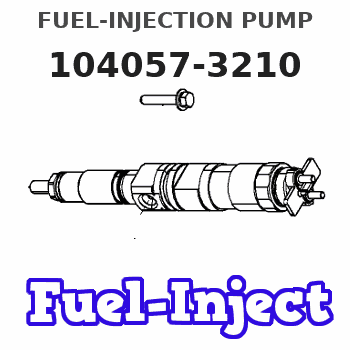

Information fuel-injection pump

BOSCH

9 410 617 015

9410617015

ZEXEL

104057-3210

1040573210

NIIGATA-URAWA

73047012A

73047012a

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104057-3210 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE | 105011-7310 |

Scheme ###:

| 5. | [1] | 141170-6920 | PLUNGER-AND-BARREL ASSY |

| 7. | [1] | 141106-8200 | CAPSULE |

| 8. | [1] | 029341-0010 | GASKET |

| 12. | [1] | 141110-8020 | DELIVERY-VALVE ASSEMBLY |

| 13. | [1] | 141112-0600 | COMPRESSION SPRING |

| 16. | [1] | 141115-4400 | GASKET |

| 17. | [1] | 141126-9420 | FITTING |

| 20. | [1] | 029633-2040 | O-RING |

| 50. | [1] | 141215-0300 | COMPRESSION SPRING |

| 51. | [1] | 141216-0100 | SLOTTED WASHER |

| 52. | [1] | 141217-2700 | SLOTTED WASHER |

| 53. | [1] | 141218-4600 | PLUNGER |

| 55. | [1] | 026110-6010 | LOCKING WASHER |

| 60. | [1] | 141243-0800 | CONTROL RACK |

| 61. | [1] | 141226-3000 | BLEEDER SCREW |

| 77. | [1] | 141241-0200 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 92. | [1] | 029702-2020 | INLET UNION |

| 93. | [1] | 029732-2050 | EYE BOLT |

| 94. | [2] | 026522-2740 | GASKET D26.9&22.2T1 |

| 94. | [2] | 026522-2740 | GASKET D26.9&22.2T1 |

| 110. | [1] | 140420-1600 | BLEEDER SCREW |

| 111. | [1] | 026506-1040 | GASKET D9.9&6.2T1 |

Include in #1:

106876-2000

as _

Include in #2:

104057-3210

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

9 410 617 015

73047012A NIIGATA-URAWA

FUEL-INJECTION PUMP

* K 24EA PF-1W(M) PF

* K 24EA PF-1W(M) PF

9 410 617 015

73047012C NIIGATA-TEKKOU

FUEL-INJECTION PUMP

* K 24EA PF-1W(M) PF

* K 24EA PF-1W(M) PF

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.DEF injectors are being replaced in the field and returned to Caterpillar for testing. Results of the testing are finding a large portion of the returned DEF injectors are found to be fault not repeated.This form is to be used and filled out in any case that a DEF injector is being replaced.The DEF injector troubleshooting return form needs to be completed and included within failed part returns documenting what was found that led to DEF injector replacement. Attach the photos of DEF injector tip and mount area along with a Product Status Report to the SIMS claim.References

Table 1

Engine Publication Type Media Number

C7.1 Troubleshooting UENR0668

Testing and Adjusting UENR4467

Disassembly and Assembly UENR4468

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly and Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly and Assembly UENR0131

C15/C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly and Assembly UENR0132 Procedure

What code are you troubleshooting? __________

Follow the correct troubleshooting procedure. Reference Table 1 for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document those results in Tables 2, 3, and 4.Tables

Table 2

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test Pass / Fail

3 DEF Concentration Test % at 20° C (68° F)

Illustration 1 g06175415

Table 3

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Result Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injectors from the applicable harness.

3 Inspect the connector for damage and debris.

4 Measure the temperature of the injector (aluminum body). C

5 Connect two 398-4987 Probes to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector. Reference Illustration 1 for example.

6 Measure the resistance of the DEF injector. Ohms

Table 4

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Aftertreatment SCR System Dosing - Test"

2 Remove the injector from the DPF outlet.

3 Take a photograph of the DEF injector mount on the DPF outlet and the tip of the DEF injector.

4 Install the injector on the beaker.

5 Run the DEF System Dosing Accuracy test through Cat® Electronic Technician (ET).

6 Use the beaker to measure the amount of fluid from the dosing test. ml

7 Repeat the test to verify consistency. ml

8 Install the injector back onto the DPF outlet.

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.DEF injectors are being replaced in the field and returned to Caterpillar for testing. Results of the testing are finding a large portion of the returned DEF injectors are found to be fault not repeated.This form is to be used and filled out in any case that a DEF injector is being replaced.The DEF injector troubleshooting return form needs to be completed and included within failed part returns documenting what was found that led to DEF injector replacement. Attach the photos of DEF injector tip and mount area along with a Product Status Report to the SIMS claim.References

Table 1

Engine Publication Type Media Number

C7.1 Troubleshooting UENR0668

Testing and Adjusting UENR4467

Disassembly and Assembly UENR4468

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly and Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly and Assembly UENR0131

C15/C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly and Assembly UENR0132 Procedure

What code are you troubleshooting? __________

Follow the correct troubleshooting procedure. Reference Table 1 for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document those results in Tables 2, 3, and 4.Tables

Table 2

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test Pass / Fail

3 DEF Concentration Test % at 20° C (68° F)

Illustration 1 g06175415

Table 3

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Result Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injectors from the applicable harness.

3 Inspect the connector for damage and debris.

4 Measure the temperature of the injector (aluminum body). C

5 Connect two 398-4987 Probes to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector. Reference Illustration 1 for example.

6 Measure the resistance of the DEF injector. Ohms

Table 4

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Aftertreatment SCR System Dosing - Test"

2 Remove the injector from the DPF outlet.

3 Take a photograph of the DEF injector mount on the DPF outlet and the tip of the DEF injector.

4 Install the injector on the beaker.

5 Run the DEF System Dosing Accuracy test through Cat® Electronic Technician (ET).

6 Use the beaker to measure the amount of fluid from the dosing test. ml

7 Repeat the test to verify consistency. ml

8 Install the injector back onto the DPF outlet.