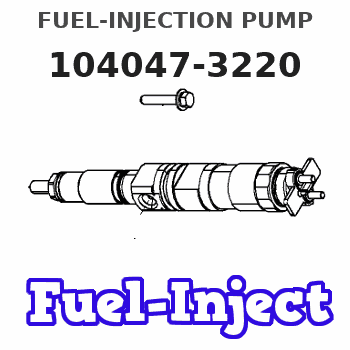

Information fuel-injection pump

BOSCH

9 410 617 289

9410617289

ZEXEL

104047-3220

1040473220

KUBOTA

1722606202

1722606202

Rating:

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 104047-3220 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105111-3030 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 27.9{285} |

| 10. | NOZZLE-HOLDER | 105041-7000 |

| 11. | NOZZLE | 105010-2320 |

Scheme ###:

| 5. | [1] | 141154-4220 | PLUNGER-AND-BARREL ASSY |

| 6. | [1] | 029332-5020 | GASKET D30&25T0.5 |

| 7. | [1] | 141106-7900 | CAPSULE |

| 8. | [1] | 029330-8050 | GASKET |

| 12. | [1] | 141140-4720 | DELIVERY-VALVE ASSEMBLY |

| 13. | [1] | 141112-0300 | COMPRESSION SPRING |

| 16. | [1] | 141115-4900 | GASKET |

| 17. | [1] | 141136-2520 | FITTING |

| 20. | [1] | 029632-9020 | O-RING |

| 50. | [1] | 141215-1900 | COMPRESSION SPRING |

| 51. | [1] | 141216-2400 | SLOTTED WASHER |

| 52. | [1] | 141217-1500 | SLOTTED WASHER |

| 53. | [1] | 141218-3700 | GUIDE |

| 55. | [1] | 141220-0300 | LOCKING WASHER |

| 60. | [1] | 141230-8300 | CONTROL RACK |

| 61. | [1] | 141226-3100 | BLEEDER SCREW |

| 77. | [1] | 141241-0600 | CONTROL SLEEVE |

| 81. | [1] | 141245-2000 | POINTER |

| 82/1. | [0] | 023500-6210 | PLAIN WASHER D11&6.4T1.5 |

| 82/1. | [0] | 029300-6010 | PLAIN WASHER D11&6.4T0.8 |

| 82/1. | [0] | 029300-6020 | PLAIN WASHER D11&6.4T0.35 |

| 83. | [1] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 92. | [1] | 027118-1540 | INLET UNION |

| 93. | [1] | 029731-8200 | EYE BOLT |

| 94. | [2] | 026518-2240 | GASKET D21.9&18.2T1 |

| 110. | [1] | 140420-1600 | BLEEDER SCREW |

| 111. | [1] | 026506-1040 | GASKET D9.9&6.2T1 |

| 112. | [1] | 141420-0400 | BLEEDER SCREW |

| 113. | [1] | 026506-1040 | GASKET D9.9&6.2T1 |

Include in #1:

106861-2131

as _

Include in #2:

104047-3220

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 1*******

0-500000 miles,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 6.0-hour job for Group 1

If the parts that are listed in the ACTION REQUIRED are on the engine, the engine has been previously updated and this Service Letter does not apply. Enter a claim against this service letter and charge 0.5 hours for the inspection time.

If the OEM CGI Flex line is replaced then it should be billed to your local OEM dealership as follows:

Cat Dealer Performs CGI Repair.

- Cat dealer purchases parts from Peterbilt / Kenworth dealer @ retail.

- Cat dealer performs repair (no charge to customer).

- Cat dealer files sublet invoice to Peterbilt / Kenworth dealer for parts (CAT will not increase part price to Peterbilt / Kenworth dealer) and labor reimbursement.

Invoice includes:

1) 17 digit VIN

2) Repair Order #

3) Vehicle mileage

4) Part pricing

5) Labor pricing

. Peterbilt / Kenworth dealer pays Cat dealer

. Peterbilt / Kenworth dealer files warranty claim (normal sublet) to Peterbilt / Kenworth

Peterbilt / Kenworth guarantees payment to Cat for the repairs performed.

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

*******Group 2*******

0-500000 miles,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 6.0-hour job for Group 2

If the parts that are listed in the ACTION REQUIRED are on the engine, the engine has been previously updated and this Service Letter does not apply. Enter a claim against this service letter and charge 0.5 hours for the inspection time.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Step 1:

Follow instructions outlined in REHS4803.

Step 2:

Attach Data Log of successful regen and attach Air Systems Verification Test report to the Warranty report and add Technician's CWS or SSO ID in the Technicians Name field of the "Warranty Report - User Information screen. See example on page 2 of REHS4803.

NOTE 1:

The seating of the heater wire to the ARD head is critical. There have been some cases of the heater wire interfering with the ARD head and not allowing it to seat properly. Refer to Image 1.1.1 for an example of proper seating.

If the heater wire hex interferes with the ARD head, use a file on the heater wire hex to allow proper seating (Image 1.1.2). DO NOT USE any cleaner after removing material from the hex as it can cause a heater failure. Usually less than 2mm reduction is necessary if proper seating does not take place.

Image1.1.1

Image1.1.2