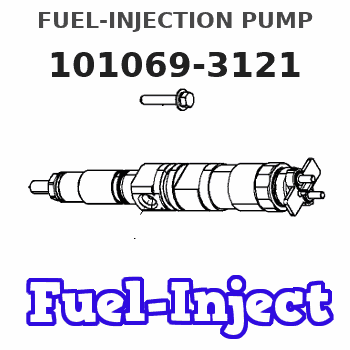

Information fuel-injection pump

BOSCH

9 410 612 792

9410612792

ZEXEL

101069-3121

1010693121

HINO

221002070A

221002070a

Rating:

Scheme ###:

| 1. | [1] | 131071-3220 | PUMP HOUSING |

| 1/30. | [3] | 029040-6220 | STUD |

| 1/35A. | [1] | 131400-0100 | ADAPTOR |

| 1/40. | [1] | 131423-0300 | ADAPTOR |

| 1/40A. | [1] | 131420-0420 | BLEEDER SCREW |

| 2. | [1] | 131028-6020 | COVER |

| 2/2. | [1] | 131011-0800 | GASKET |

| 3. | [2] | 131017-1000 | FLAT-HEAD SCREW |

| 5. | [2] | 029340-6020 | GASKET D10&6.5T1.00 |

| 16. | [6] | 131034-1401 | CAPSULE |

| 21. | [3] | 139206-0400 | UNION NUT |

| 23. | [1] | 029633-1010 | O-RING |

| 30. | [6] | 131151-3020 | PLUNGER-AND-BARREL ASSY |

| 36. | [6] | 131110-1820 | DELIVERY-VALVE ASSEMBLY |

| 37. | [6] | 131112-0600 | COILED SPRING |

| 40. | [6] | 131115-0200 | GASKET |

| 41. | [6] | 131116-0400 | FITTING |

| 45. | [3] | 131122-0520 | PLATE |

| 55. | [6] | 131200-0620 | TAPPET |

| 55/2. | [1] | 131201-0100 | UNION NUT |

| 55/3. | [1] | 131202-0100 | HEXAGON SCREW |

| 55/4. | [1] | 131203-0200 | BEARING PIN |

| 55/5. | [1] | 131204-1000 | ROLLER |

| 55/6. | [1] | 131205-0500 | BUSHING |

| 55/7. | [1] | 131206-0200 | SLIDER |

| 61. | [6] | 131215-2400 | COMPRESSION SPRING |

| 62. | [6] | 131216-0100 | SLOTTED WASHER |

| 63. | [6] | 131217-0100 | SLOTTED WASHER |

| 67. | [1] | 131256-0000 | CONTROL RACK |

| 68. | [1] | 131226-0300 | FLAT-HEAD SCREW |

| 76. | [6] | 131240-0100 | PINION |

| 77. | [6] | 131241-0100 | CONTROL SLEEVE |

| 78. | [6] | 131242-0100 | FLAT-HEAD SCREW |

| 90. | [1] | 131370-0000 | CAMSHAFT |

| 91. | [1] | 028001-7010 | BEARING PLATE |

| 91A. | [1] | 016630-2030 | BEARING PLATE |

| 91B. | [1] | 028201-7020 | BEARING PLATE |

| 91E. | [1] | 016630-2030 | BEARING PLATE |

| 91F. | [1] | 028201-7020 | BEARING PLATE |

| 92. | [1] | 131302-0300 | SPACER RING |

| 92A. | [1] | 131302-0300 | SPACER RING |

| 93/1. | [0] | 029311-7010 | SHIM D22&17T0.1 |

| 93/1. | [0] | 029311-7020 | SHIM D22&17T0.12 |

| 93/1. | [0] | 029311-7030 | SHIM D22&17T0.14 |

| 93/1. | [0] | 029311-7040 | SHIM D22&17T0.16 |

| 93/1. | [0] | 029311-7050 | SHIM D22&17T0.18 |

| 93/1. | [0] | 029311-7060 | SHIM D22&17T0.5 |

| 93/1. | [0] | 029311-7070 | SHIM D22&17T1.0 |

| 93/1. | [0] | 029311-7090 | SHIM D22&17T0.3 |

| 93/1. | [0] | 029311-7210 | SHIM D22&17T0.7 |

| 93/1. | [0] | 029311-7220 | SHIM D22&17T1.4 |

| 93/1. | [0] | 139417-0000 | SHIM D22&17T2.4 |

| 93A/1. | [0] | 029311-7010 | SHIM D22&17T0.1 |

| 93A/1. | [0] | 029311-7020 | SHIM D22&17T0.12 |

| 93A/1. | [0] | 029311-7030 | SHIM D22&17T0.14 |

| 93A/1. | [0] | 029311-7040 | SHIM D22&17T0.16 |

| 93A/1. | [0] | 029311-7050 | SHIM D22&17T0.18 |

| 93A/1. | [0] | 029311-7060 | SHIM D22&17T0.5 |

| 93A/1. | [0] | 029311-7070 | SHIM D22&17T1.0 |

| 93A/1. | [0] | 029311-7090 | SHIM D22&17T0.3 |

| 93A/1. | [0] | 029311-7210 | SHIM D22&17T0.7 |

| 93A/1. | [0] | 029311-7220 | SHIM D22&17T1.4 |

| 93A/1. | [0] | 139417-0000 | SHIM D22&17T2.4 |

| 95. | [1] | 131306-0800 | BEARING SHELL |

| 96. | [2] | 029050-5010 | FLAT-HEAD SCREW M5P0.8L32 |

| 97. | [2] | 026505-0940 | GASKET |

| 100A. | [1] | 139617-0000 | PACKING RING |

| 101A. | [1] | 131330-3100 | COVER |

| 102A. | [1] | 131563-0900 | SLIDING PIECE |

| 104A. | [4] | 020006-1440 | BLEEDER SCREW M6P1L14 |

| 106A. | [1] | 029634-4020 | O-RING |

| 112A. | [1] | 025803-1610 | WOODRUFF KEY |

| 117A. | [1] | 029731-4080 | EYE BOLT |

| 118A. | [2] | 139514-0300 | GASKET |

| 130. | [1] | 131424-4120 | OVER FLOW VALVE |

| 132. | [2] | 139512-0600 | GASKET |

| 152. | [1] | 029731-6030 | EYE BOLT |

| 154. | [2] | 139516-0200 | GASKET |

| 334. | [1] | 134430-0200 | EYE BOLT |

| 336. | [2] | 139510-0300 | GASKET |

| 360A. | [1] | 131496-0300 | POINTER |

| 361A. | [2] | 139006-0800 | BLEEDER SCREW |

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

If the procedure did not correct the issue, contact your Cat dealer Technical Communicator (TC). For further assistance, your TC can confer with the Dealer Solutions Network (DSN).E1156(1) - Filter intake pressure greater than 10 kPa (1.50 psi) for more than 10 seconds. Refer to Table14 for troubleshooting.E1156(2) - Filter intake pressure greater than 15 kPa (2.25 psi) for more than 10 seconds. Refer to Table14 for troubleshooting.A faulty sensor may cause this diagnostic code. First determine that the sensor is not faulty.

Table 14

Troubleshooting Test Steps Values Results

1. Check for Associated Diagnostic Codes.

A. Establish communication between the Cat® Electronic Technician (ET) and the engine Electronic Control Module (ECM).

B. Troubleshoot any associated diagnostic codes that are present before continuing with this procedure.

Associated Diagnostic Codes

Result: An associated diagnostic code is not present.

Proceed to Test Step 2.

Result: An associated diagnostic code is active or logged.

1. Troubleshoot the associated diagnostic code before continuing with this procedure.

2. Service Maintenance.

A. Determine the most recent cleaning of the Wall Flow Filter (WFF).

Cleaning Interval

Result: The WFF was cleaned within the last 1000 hours.

Proceed to Test Step 3.

Result: The WFF was not cleaned within the last 1000 hours.

Proceed to Test Step 4.

3. Check for Contamination.

A. Reset all active codes and clear all logged codes.

B. Remove the WFF.

C. Check for contamination on the face of the WFF.

Contamination

Result: There is no sign of oil, fuel, or coolant on the WFF.

Proceed to Test Step 4.

Result: There is oil, fuel, or coolant on the WFF.

1. Diagnose the cause of the contamination.

2. The engine must be run with no load at 1400 rpm for at least 15 minutes, or until there is no white smoke.

3. If white smoke continues, or if the diagnostic code remains active, proceed to Test Step 5.

4. Clean the WFF.

A. Clean the WFF. Refer to "Wall Flow Diesel Particulate Filter - Clean".

B. Reset all active codes and clear all logged codes.

Clean was successful

Result: Cleaning the WFF was successful.

Return the machine to service.

Result: Cleaning the WFF was not successful.

1. Troubleshoot any diagnostic codes that are present, if no codes are present, proceed to Test Step 6.

5. Replace the WFF.

Replacement was successful

Result: Replacing the WFF was successful.

Return the machine to service.

If the procedure did not correct the issue, contact your Cat dealer Technical Communicator (TC). For further assistance, your TC can confer with the Dealer Solutions Network (DSN).Exhaust Temperature Is High

Certain operating conditions may cause the exhaust temperature to increase to a level that may damage engine components.Probable Causes

Boost Leak

Engine operating conditions

High altitude

Obstructed aftercooler

Table 15

Troubleshooting Test Steps Values Results

1. Check for Boost Leakage.

A. Apply a light load to the engine and check for boost leakage.

Boost Leaks

Result: Boost leakage was found.

Repair: Repair the leaks. Return the machine to service.

Result: Boost leakage was not found.

Proceed to Test Step 2.

2. Check the Engine Operating Conditions.

A. Check the histogram to determine if the high exhaust temperature was due to normal operation.

When possible, interview the operator. Determine if the engine is being operated under heavy load. Ensure that the engine is being operated at the

Table 14

Troubleshooting Test Steps Values Results

1. Check for Associated Diagnostic Codes.

A. Establish communication between the Cat® Electronic Technician (ET) and the engine Electronic Control Module (ECM).

B. Troubleshoot any associated diagnostic codes that are present before continuing with this procedure.

Associated Diagnostic Codes

Result: An associated diagnostic code is not present.

Proceed to Test Step 2.

Result: An associated diagnostic code is active or logged.

1. Troubleshoot the associated diagnostic code before continuing with this procedure.

2. Service Maintenance.

A. Determine the most recent cleaning of the Wall Flow Filter (WFF).

Cleaning Interval

Result: The WFF was cleaned within the last 1000 hours.

Proceed to Test Step 3.

Result: The WFF was not cleaned within the last 1000 hours.

Proceed to Test Step 4.

3. Check for Contamination.

A. Reset all active codes and clear all logged codes.

B. Remove the WFF.

C. Check for contamination on the face of the WFF.

Contamination

Result: There is no sign of oil, fuel, or coolant on the WFF.

Proceed to Test Step 4.

Result: There is oil, fuel, or coolant on the WFF.

1. Diagnose the cause of the contamination.

2. The engine must be run with no load at 1400 rpm for at least 15 minutes, or until there is no white smoke.

3. If white smoke continues, or if the diagnostic code remains active, proceed to Test Step 5.

4. Clean the WFF.

A. Clean the WFF. Refer to "Wall Flow Diesel Particulate Filter - Clean".

B. Reset all active codes and clear all logged codes.

Clean was successful

Result: Cleaning the WFF was successful.

Return the machine to service.

Result: Cleaning the WFF was not successful.

1. Troubleshoot any diagnostic codes that are present, if no codes are present, proceed to Test Step 6.

5. Replace the WFF.

Replacement was successful

Result: Replacing the WFF was successful.

Return the machine to service.

If the procedure did not correct the issue, contact your Cat dealer Technical Communicator (TC). For further assistance, your TC can confer with the Dealer Solutions Network (DSN).Exhaust Temperature Is High

Certain operating conditions may cause the exhaust temperature to increase to a level that may damage engine components.Probable Causes

Boost Leak

Engine operating conditions

High altitude

Obstructed aftercooler

Table 15

Troubleshooting Test Steps Values Results

1. Check for Boost Leakage.

A. Apply a light load to the engine and check for boost leakage.

Boost Leaks

Result: Boost leakage was found.

Repair: Repair the leaks. Return the machine to service.

Result: Boost leakage was not found.

Proceed to Test Step 2.

2. Check the Engine Operating Conditions.

A. Check the histogram to determine if the high exhaust temperature was due to normal operation.

When possible, interview the operator. Determine if the engine is being operated under heavy load. Ensure that the engine is being operated at the