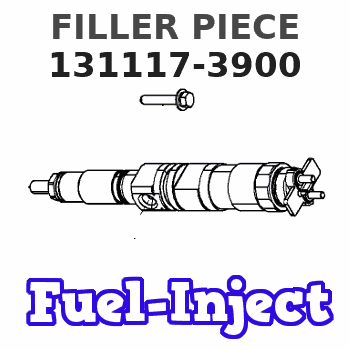

Information filler piece

BOSCH

9 411 610 569

9411610569

ZEXEL

131117-3900

1311173900

HINO

221171140A

221171140a

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$60.33

22 Mar 2024

2.0[0.90] pounds

US: Wheels Depot

Rear Dynamic Friction Company 3000 Semi-Met Brake Pads 1311-1739-00

Dynamic Friction Company Designed to deliver trouble-free, consistent performance || Right for your vehicle and lifestyle || Made from high-quality materials for ultimate durability || Manufactured to meet or exceed strict quality requirements || If you have any questions or need fitment information for your vehicle, please contact with us

Dynamic Friction Company Designed to deliver trouble-free, consistent performance || Right for your vehicle and lifestyle || Made from high-quality materials for ultimate durability || Manufactured to meet or exceed strict quality requirements || If you have any questions or need fitment information for your vehicle, please contact with us

Include in ###:

Number on scheme 42/1

1010408701

as FILLER PIECE

T4.9

1010409231

as FILLER PIECE

1010409233

as FILLER PIECE

T4.9

1010609581

as FILLER PIECE

1010609690

as FILLER PIECE

T4.9

Cross reference number

Zexel num

Bosch num

Firm num

Name

131117-3900

9 411 610 569

221171140A HINO

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

131117-3900

9 411 610 569

ME704347 MITSUBISHI

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

Information:

Removal of Fuel System

To prevent dust from entering the fuel system, cover all openings in the injection pump, nozzle inlet connectors and injection pipes.

Removal of Fuel Injection Pump

Removal of fuel injection pump (1)

Removal of fuel injection pump (2)(1) Check the alignment marks stamped on the flange of the fuel injection pump and the pump mounting flange.(2) Remove the front cover from the engine.(3) Place alignment marked on the fuel injection pump gear and idler gear.(4) Unscrew the mounting bolts from the fuel injection pump flange, and remove the fuel injection pump together with the flange from the front plate. (a) After the fuel injection pump is removed, do not turn the engine.(b) When removing the pump gear, loosen the gear retaining nut while the pump is mounted on the engine.Disassembly, Inspection and Reassembly of Fuel System

Disassembly of Fuel Injection Nozzles

Inspection of Fuel Injection Nozzles

Inspection of fuel injection nozzle valve openingCheck each fuel injection nozzle for the following, and if defects are found, repair or replace the fuel injection nozzle.(1) Inspection of injection start pressure(a) Install each fuel injection nozzle on the nozzle tester, and move the handle up and down to release air.(b) Operate the handle of the tester at a rate of about 1 stroke per second, and read the indication on the pressure gage. The indication rises slowly, and the indicator oscillates during spraying. To obtain the injection start pressure value, read the indication when the indicator starts to oscillate.(c) If the injection start pressure deviates significantly from the standard value, disassemble the fuel injection nozzle, and make an adjustment by changing the washer thickness.

Replacement of fuel injection nozzle tip 0.1 mm [0.0039 in.] thickness of shims will change the injection pressure 0.98 Mpa (10 kgf/cm2 [142 psi]. The shims are available in 10 different thickness from 1.25 to 1.70 mm [0.0492 to 0.0669 in.] increment of 0.05 mm [0.0020 in.]

Never tap the tip of the nozzle tip when removing the nozzle tip.

(2) Inspection f fuel injection nozzle spray pattern

Inspection of spray pattern of fuel injection nozzle(a) When inspecting each fuel injection nozzle with the nozzle tester, also check the nozzle for clogs, spray pattern and leakage.(b) Make sure that the fuel is sprayed straight from the nozzle when the handle of the tester is operated at a rate of about 1 stroke per second.(3) Cleaning and replacement of faulty nozzles

Cleaning of fuel injection nozzle tip(a) Loosen the nozzle retaining nut, remove the nozzle tip, and clean the needle valve and body.

Never tap the tip of the nozzle tip when removing the nozzle tip.

(b) Use a fresh cleaning solution to clean the needle valve and body. after cleaning, assemble the needle valve and body in clean diesel fuel. The needle valve and body are precision finished. Handle them carefully, and do not change the combination of parts.(c) Tighten the nozzle retaining nut on the nozzle tip to the specified torque.(d) If the spray pattern is still not acceptable after adjustment and cleaning, replace the nozzle tip.

To prevent dust from entering the fuel system, cover all openings in the injection pump, nozzle inlet connectors and injection pipes.

Removal of Fuel Injection Pump

Removal of fuel injection pump (1)

Removal of fuel injection pump (2)(1) Check the alignment marks stamped on the flange of the fuel injection pump and the pump mounting flange.(2) Remove the front cover from the engine.(3) Place alignment marked on the fuel injection pump gear and idler gear.(4) Unscrew the mounting bolts from the fuel injection pump flange, and remove the fuel injection pump together with the flange from the front plate. (a) After the fuel injection pump is removed, do not turn the engine.(b) When removing the pump gear, loosen the gear retaining nut while the pump is mounted on the engine.Disassembly, Inspection and Reassembly of Fuel System

Disassembly of Fuel Injection Nozzles

Inspection of Fuel Injection Nozzles

Inspection of fuel injection nozzle valve openingCheck each fuel injection nozzle for the following, and if defects are found, repair or replace the fuel injection nozzle.(1) Inspection of injection start pressure(a) Install each fuel injection nozzle on the nozzle tester, and move the handle up and down to release air.(b) Operate the handle of the tester at a rate of about 1 stroke per second, and read the indication on the pressure gage. The indication rises slowly, and the indicator oscillates during spraying. To obtain the injection start pressure value, read the indication when the indicator starts to oscillate.(c) If the injection start pressure deviates significantly from the standard value, disassemble the fuel injection nozzle, and make an adjustment by changing the washer thickness.

Replacement of fuel injection nozzle tip 0.1 mm [0.0039 in.] thickness of shims will change the injection pressure 0.98 Mpa (10 kgf/cm2 [142 psi]. The shims are available in 10 different thickness from 1.25 to 1.70 mm [0.0492 to 0.0669 in.] increment of 0.05 mm [0.0020 in.]

Never tap the tip of the nozzle tip when removing the nozzle tip.

(2) Inspection f fuel injection nozzle spray pattern

Inspection of spray pattern of fuel injection nozzle(a) When inspecting each fuel injection nozzle with the nozzle tester, also check the nozzle for clogs, spray pattern and leakage.(b) Make sure that the fuel is sprayed straight from the nozzle when the handle of the tester is operated at a rate of about 1 stroke per second.(3) Cleaning and replacement of faulty nozzles

Cleaning of fuel injection nozzle tip(a) Loosen the nozzle retaining nut, remove the nozzle tip, and clean the needle valve and body.

Never tap the tip of the nozzle tip when removing the nozzle tip.

(b) Use a fresh cleaning solution to clean the needle valve and body. after cleaning, assemble the needle valve and body in clean diesel fuel. The needle valve and body are precision finished. Handle them carefully, and do not change the combination of parts.(c) Tighten the nozzle retaining nut on the nozzle tip to the specified torque.(d) If the spray pattern is still not acceptable after adjustment and cleaning, replace the nozzle tip.

Have questions with 131117-3900?

Group cross 131117-3900 ZEXEL

Hino

131117-3900

9 411 610 569

221171140A

FILLER PIECE

Mitsubishi

131117-3900

9 411 610 569

ME704347

FILLER PIECE