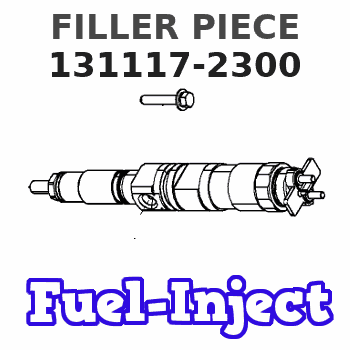

Information filler piece

BOSCH

9 411 610 093

9411610093

ZEXEL

131117-2300

1311172300

ISUZU

5156290450

5156290450

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$32.20

26 Nov 2024

Amazon.com

Dynamic Friction Company 3000 Semi-Metallic Brake Pads 1311-1723-00-Front Set

Dynamic Friction Company Excellent pad life and rotor friendly || Virtually noise free and low dust || Formulated for passenger vehicles and light duty trucks || Stable friction performance across a wide temperature range || 100% Copper Free Eco Friendly Formulation [California/Washington 2025] || If the “Confirmed Fit” bar appears at the top of this page, please check the “Confirmed Fit” bar before buying this product to ensure this product works for your vehicle. If the “Confirmed Fit” bar has an “i” in a blue circle, this product has additional notes. Please hover over the “i” on the bar to see notes before making your purchase.

Dynamic Friction Company Excellent pad life and rotor friendly || Virtually noise free and low dust || Formulated for passenger vehicles and light duty trucks || Stable friction performance across a wide temperature range || 100% Copper Free Eco Friendly Formulation [California/Washington 2025] || If the “Confirmed Fit” bar appears at the top of this page, please check the “Confirmed Fit” bar before buying this product to ensure this product works for your vehicle. If the “Confirmed Fit” bar has an “i” in a blue circle, this product has additional notes. Please hover over the “i” on the bar to see notes before making your purchase.

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

131117-2300

9 411 610 093

5156290450 ISUZU

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

131117-2300

9 411 610 093

221171090A HINO

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

131117-2300

9 411 610 093

221171160A HINO

FILLER PIECE

A C 14FL STOPPER parts(A,AD) Others

A C 14FL STOPPER parts(A,AD) Others

131117-2300

9 411 610 093

ME704288 MITSUBISHI

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

131117-2300

9 411 610 093

16764T9300 NISSAN

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

131117-2300

9 411 610 093

16779Z9000 NISSAN-DIESEL

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

131117-2300

9 411 610 093

SL0124122 MAZDA

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

Information:

Determination Of Overhaul Timing

Generally, the engine needs an overhaul when the compression pressure of the engine becomes low, and the amounts of engine oil consumption and blow-by gas increase.Reduced power output, increased fuel consumption, low oil pressure, difficult in starting, and increased operating noise are also signs that suggest the need for an overhaul; however, since these problems can be caused by various factors, they do not serve as reliable criteria for determining the need for an overhaul.Reduced compression pressure manifests a variety of symptoms, thus making it difficult to accurately determine when the engine needs an overhaul. The following shows typical problems caused by reduced compression pressure.(1) Decreased output power(2) Increased fuel consumption(3) Increased engine oil consumption(4) Increased blow-by gas from breather due to leakage of combustion gas through worn cylinder liners and piston rings(5) Increased gas leakage due to poor seating of inlet and exhaust valves(6) Difficulty in starting(7) Increased noise from engine parts(8) Abnormal exhaust color after warm-up operationThe engine can exhibit these conditions in various combinations.Some of these problems are directly caused by worn engine parts, while others are not.Phenomena described in (2) and (6) can also result from improper injection volume, incorrect fuel injection timing, worn plungers, defective nozzles, and faulty conditions of electrical devices such as battery, starter and alternator.The most valid reason to overhaul an engine is a decrease in the compression pressure due to worn cylinder liners and pistons, as described in (4), and once this is determined, other symptoms should be taken into consideration in order to make the final judgement of whether the engine needs an overhaul.Measurement of Compression Pressure

Preparation For Inspection

Check the following before inspection.(1) Make sure that the engine oil, air cleaner, starter, battery, etc. are in normal operating condition.

Measurement of compression pressureInspection

(1) Move the control lever to the Stop position.(2) Remove the glow plugs from all cylinders, and attach the gage adapter and compression gage to the cylinder to be tested. (3) Crank the engine with the starter, and read the compression gage indication when the indication stabilizes.(4) If the measured compression pressure is lower than the limit, consider overhauling the engine.

(a) Measure the compression pressure in all cylinders.(b) As compression pressure varies with the engine speed, measure the engine speed at the same time.

Measure the compression pressure while the engine is running at 150 to 200 min-1. The oil and coolant temperatures should be between 20 and 30 °C [68 and 86°F].

(a) Measure the compression pressure at regular intervals to keep the record of changes in compression pressure.(b) Compression pressure will be slightly higher when the engine is new or immediately after an overhaul due to tight clearances of piston rings and valve seats, but it decreases to the standard level after the parts break in.

Generally, the engine needs an overhaul when the compression pressure of the engine becomes low, and the amounts of engine oil consumption and blow-by gas increase.Reduced power output, increased fuel consumption, low oil pressure, difficult in starting, and increased operating noise are also signs that suggest the need for an overhaul; however, since these problems can be caused by various factors, they do not serve as reliable criteria for determining the need for an overhaul.Reduced compression pressure manifests a variety of symptoms, thus making it difficult to accurately determine when the engine needs an overhaul. The following shows typical problems caused by reduced compression pressure.(1) Decreased output power(2) Increased fuel consumption(3) Increased engine oil consumption(4) Increased blow-by gas from breather due to leakage of combustion gas through worn cylinder liners and piston rings(5) Increased gas leakage due to poor seating of inlet and exhaust valves(6) Difficulty in starting(7) Increased noise from engine parts(8) Abnormal exhaust color after warm-up operationThe engine can exhibit these conditions in various combinations.Some of these problems are directly caused by worn engine parts, while others are not.Phenomena described in (2) and (6) can also result from improper injection volume, incorrect fuel injection timing, worn plungers, defective nozzles, and faulty conditions of electrical devices such as battery, starter and alternator.The most valid reason to overhaul an engine is a decrease in the compression pressure due to worn cylinder liners and pistons, as described in (4), and once this is determined, other symptoms should be taken into consideration in order to make the final judgement of whether the engine needs an overhaul.Measurement of Compression Pressure

Preparation For Inspection

Check the following before inspection.(1) Make sure that the engine oil, air cleaner, starter, battery, etc. are in normal operating condition.

Measurement of compression pressureInspection

(1) Move the control lever to the Stop position.(2) Remove the glow plugs from all cylinders, and attach the gage adapter and compression gage to the cylinder to be tested. (3) Crank the engine with the starter, and read the compression gage indication when the indication stabilizes.(4) If the measured compression pressure is lower than the limit, consider overhauling the engine.

(a) Measure the compression pressure in all cylinders.(b) As compression pressure varies with the engine speed, measure the engine speed at the same time.

Measure the compression pressure while the engine is running at 150 to 200 min-1. The oil and coolant temperatures should be between 20 and 30 °C [68 and 86°F].

(a) Measure the compression pressure at regular intervals to keep the record of changes in compression pressure.(b) Compression pressure will be slightly higher when the engine is new or immediately after an overhaul due to tight clearances of piston rings and valve seats, but it decreases to the standard level after the parts break in.

Have questions with 131117-2300?

Group cross 131117-2300 ZEXEL

Isuzu

131117-2300

9 411 610 093

5156290450

FILLER PIECE

Hino

131117-2300

9 411 610 093

221171090A

FILLER PIECE

131117-2300

9 411 610 093

221171160A

FILLER PIECE

Mitsubishi

131117-2300

9 411 610 093

ME704288

FILLER PIECE

Nissan

131117-2300

9 411 610 093

16764T9300

FILLER PIECE

Nissan-Diesel

131117-2300

9 411 610 093

16779Z9000

FILLER PIECE

Mazda

131117-2300

9 411 610 093

SL0124122

FILLER PIECE