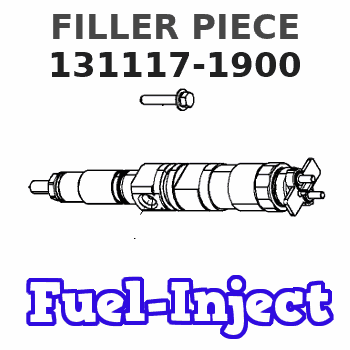

Information filler piece

BOSCH

9 411 617 042

9411617042

ZEXEL

131117-1900

1311171900

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Dynamic Friction Company 3000 Semi-Metallic Brake Pads 1311-1719-00-Rear Set

Dynamic Friction Company Brake Pads: Includes (4) Dynamic Friction Company Rear 3000 Semi-Metallic Brake Pads for improved braking performance || Reliable Semi-Metallic Formula: Designed for passenger vehicles and light-duty trucks with consistent braking performance || Long-Lasting Durability: Provides stable friction, long pad wear, and rotor-friendly performance across various conditions || Clean & Quiet Braking: Engineered for low dust and noise, ensuring a smooth and quiet ride || Compatible for (verify fitment details with AmazonConfirmFit bar above): 2012-2016 Chrysler Town & Country, Dodge Grand Caravan, 2009-2013 Dodge Journey, 2012-2015 Ram C/V, 2009-2014 Volkswagen Routan

Dynamic Friction Company Brake Pads: Includes (4) Dynamic Friction Company Rear 3000 Semi-Metallic Brake Pads for improved braking performance || Reliable Semi-Metallic Formula: Designed for passenger vehicles and light-duty trucks with consistent braking performance || Long-Lasting Durability: Provides stable friction, long pad wear, and rotor-friendly performance across various conditions || Clean & Quiet Braking: Engineered for low dust and noise, ensuring a smooth and quiet ride || Compatible for (verify fitment details with AmazonConfirmFit bar above): 2012-2016 Chrysler Town & Country, Dodge Grand Caravan, 2009-2013 Dodge Journey, 2012-2015 Ram C/V, 2009-2014 Volkswagen Routan

Include in ###:

Cross reference number

Zexel num

Bosch num

Firm num

Name

131117-1900

9 411 617 042

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

131117-1900

9 411 617 042

9411617042 BOSCH

FILLER PIECE

C 14FL STOPPER parts(A,AD) Others

C 14FL STOPPER parts(A,AD) Others

Information:

1. If necessary, remove the injector clamp bolt and clamp.

Illustration 1. Remove Clamp Bolt And Clamp.2. Remove jumper tube by removing two socket head cap screws on one end and loosening the tube nut on the other end. Refer to Illustrations 2 and 3.

Illustration 2. Remove Two Cap Screws.

Illustration 3. Loosen Tube Nut.

Make sure the small seat, shown in Illustration 4, is removed. Do not allow the seat to fall into any engine cavity, which could result in damage if unintentionally left inside the engine.Also, make sure the jumper tube is kept clean at all times. Dirt or other debris can get into the engine with this tube removed and cause possible damage.

Illustration 4. Do Not Lose Or Misplace Tube Seat.3. Remove four bolts and rocker arm assembly.

Illustration 5. Remove Rocker Arm Assembly.4. Remove inlet manifold bolt, as shown in Illustration 6.

Illustration 6. Remove Manifold Bolt.5. Remove the unit injector.6. Install a new injector brass sleeve or inspect and ream the existing sleeves as outlined in Tool Operating Manual NEHS0675. It is not necessary to ream new sleeves when using this procedure.7. Install the unit injector.

Do not install the injectors "off-engine" because the injector tip will protrude from the head and be subject to damage. If the injectors are installed off-engine, make sure the bottom surface of the head is raised off the surface of the work bench.

8. Install the injector forcing cover (8). Make sure the extending portion (small dowel) is in the oil supply hole of the injector. Also make sure wear button (10) is in place.

Illustration 7. Install Injector Forcing Cover (8) With Wear Button (10).9. Place a small amount of 4C-5591 Thread Lubricant on top of the injector forcing cover's wear button (10) and on the threads of forcing bolt (4).

Complete lubrication of the wear button and forcing bolt must be maintained for each injector seating procedure. Failure to relubricate each part before seating the next injector may cause premature wear or tool damage. Also, make sure the forcing bolt turns freely and does not have any damaged threads.

Illustration 8. Put A Small Amount Of Thread Lubricant On Wear Button.10. Install the forcing bridge with three 7X-0457 Bolts (5) and three 9M-1974 Hard Washers (6). Put the two long legs of the forcing bridge in the two rocker arm shaft support holes closest to the injector. The short leg of the forcing bridge sits on the intake manifold bolt boss.

Illustration 9. Install Forcing Bridge.11. Tighten forcing bridge mounting bolts (5) to 28 7 N m, 2.9 0.7 meter kg, (21 5 lb. ft.).

Damage to the head could occur if bridge mounting bolts (5) are not tightened to the specified torque.

Illustration 10. Tighten Forcing Bridge Bolts.12. Tighten the forcing bolt finger tight.13. Use a 9U-5019 Torque Wrench and tighten the forcing bolts to 34 1.4 N m, 3.5

Illustration 1. Remove Clamp Bolt And Clamp.2. Remove jumper tube by removing two socket head cap screws on one end and loosening the tube nut on the other end. Refer to Illustrations 2 and 3.

Illustration 2. Remove Two Cap Screws.

Illustration 3. Loosen Tube Nut.

Make sure the small seat, shown in Illustration 4, is removed. Do not allow the seat to fall into any engine cavity, which could result in damage if unintentionally left inside the engine.Also, make sure the jumper tube is kept clean at all times. Dirt or other debris can get into the engine with this tube removed and cause possible damage.

Illustration 4. Do Not Lose Or Misplace Tube Seat.3. Remove four bolts and rocker arm assembly.

Illustration 5. Remove Rocker Arm Assembly.4. Remove inlet manifold bolt, as shown in Illustration 6.

Illustration 6. Remove Manifold Bolt.5. Remove the unit injector.6. Install a new injector brass sleeve or inspect and ream the existing sleeves as outlined in Tool Operating Manual NEHS0675. It is not necessary to ream new sleeves when using this procedure.7. Install the unit injector.

Do not install the injectors "off-engine" because the injector tip will protrude from the head and be subject to damage. If the injectors are installed off-engine, make sure the bottom surface of the head is raised off the surface of the work bench.

8. Install the injector forcing cover (8). Make sure the extending portion (small dowel) is in the oil supply hole of the injector. Also make sure wear button (10) is in place.

Illustration 7. Install Injector Forcing Cover (8) With Wear Button (10).9. Place a small amount of 4C-5591 Thread Lubricant on top of the injector forcing cover's wear button (10) and on the threads of forcing bolt (4).

Complete lubrication of the wear button and forcing bolt must be maintained for each injector seating procedure. Failure to relubricate each part before seating the next injector may cause premature wear or tool damage. Also, make sure the forcing bolt turns freely and does not have any damaged threads.

Illustration 8. Put A Small Amount Of Thread Lubricant On Wear Button.10. Install the forcing bridge with three 7X-0457 Bolts (5) and three 9M-1974 Hard Washers (6). Put the two long legs of the forcing bridge in the two rocker arm shaft support holes closest to the injector. The short leg of the forcing bridge sits on the intake manifold bolt boss.

Illustration 9. Install Forcing Bridge.11. Tighten forcing bridge mounting bolts (5) to 28 7 N m, 2.9 0.7 meter kg, (21 5 lb. ft.).

Damage to the head could occur if bridge mounting bolts (5) are not tightened to the specified torque.

Illustration 10. Tighten Forcing Bridge Bolts.12. Tighten the forcing bolt finger tight.13. Use a 9U-5019 Torque Wrench and tighten the forcing bolts to 34 1.4 N m, 3.5

Have questions with 131117-1900?

Group cross 131117-1900 ZEXEL

131117-1900

9 411 617 042

FILLER PIECE

Bosch

131117-1900

9 411 617 042

9411617042

FILLER PIECE