Information

ZEXEL

106971-3000

1069713000

HINO

220001960A

220001960a

Rating:

Cross reference number

ZEXEL

106971-3000

1069713000

HINO

220001960A

220001960a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

1324240-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-10-9-4

-3-6-5-8

-7-2

Pre-stroke

mm

4

3.9

4

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-10 deg. 27 26.5 27.5

Cal 1-10 deg. 27 26.5 27.5

Difference between angles 2

Cal 1-9 deg. 72 71.5 72.5

Cal 1-9 deg. 72 71.5 72.5

Difference between angles 3

Cal 1-4 deg. 99 98.5 99.5

Cal 1-4 deg. 99 98.5 99.5

Difference between angles 4

Cal 1-3 deg. 144 143.5 144.5

Cal 1-3 deg. 144 143.5 144.5

Difference between angles 5

Cal 1-6 deg. 171 170.5 171.5

Cal 1-6 deg. 171 170.5 171.5

Difference between angles 6

Cal 1-5 deg. 216 215.5 216.5

Cal 1-5 deg. 216 215.5 216.5

Difference between angles 7

Cal 1-8 deg. 243 242.5 243.5

Cal 1-8 deg. 243 242.5 243.5

Difference between angles 8

Cal 1-7 deg. 288 287.5 288.5

Cal 1-7 deg. 288 287.5 288.5

Difference between angles 9

Cyl.1-2 deg. 315 314.5 315.5

Cyl.1-2 deg. 315 314.5 315.5

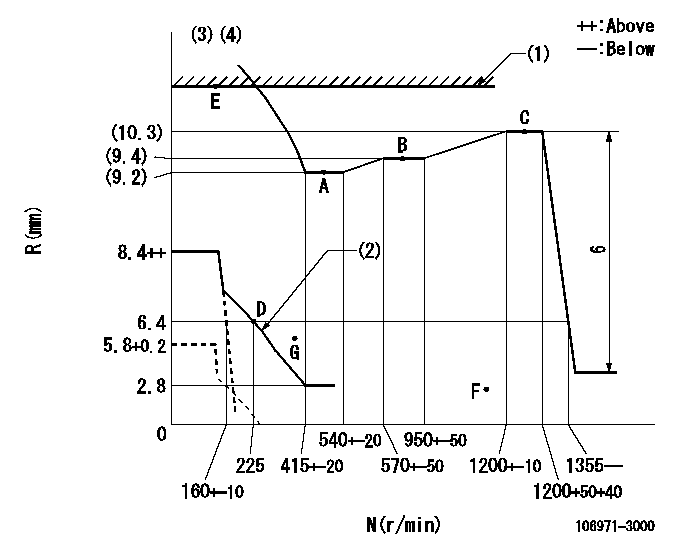

Injection quantity adjustment

Adjusting point

A

Rack position

9.2+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

113.1

110.1

116.1

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.4+-0.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

117

115

119

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.3+-0.

5

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

140.2

137.2

143.2

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.7

10.7

16.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

122

112

132

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

F

Rack position

-

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

0

0

0

Fixing the lever

*

Timer adjustment

Pump speed

r/min

950+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Beginning of damper spring operation: DL

(3)Set idle at point G (N = N1, R = R1) and confirm that the fuel injection quantity at N = N2 does not exceed F.

(4)Adjust so that the control lever's stop position is R = R2 (N = 0).

----------

DL=5.4-0.2mm N1=300r/min R1=5.4mm N2=1000r/min R2=5.8+0.2mm

----------

----------

DL=5.4-0.2mm N1=300r/min R1=5.4mm N2=1000r/min R2=5.8+0.2mm

----------

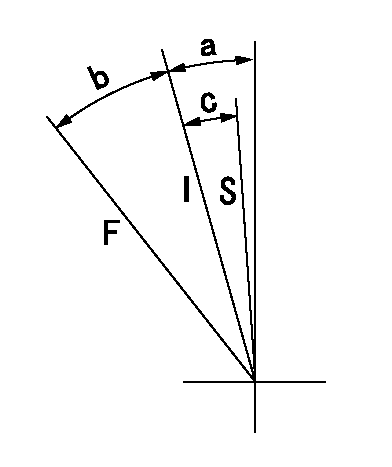

Speed control lever angle

F:Full speed

----------

----------

a=12deg+-5deg

----------

----------

a=12deg+-5deg

0000000901

F:Full load

I:Idle

S:Stop

----------

----------

a=19deg+-5deg b=36deg+-3deg c=16deg+-3deg

----------

----------

a=19deg+-5deg b=36deg+-3deg c=16deg+-3deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325-25r/min Ra=6.4mm

----------

----------

N1=325-25r/min Ra=6.4mm

----------

Information:

(1) Thickness of spacer plate ... 9.970 0.025 mm (.3925 .0010 in.) Thickness of spacer plate gasket ... 0.208 0.025 mm (.0082 .0010 in.) For height of liner over top of spacer plate make reference to Cylinder Liner Projection.(2) Camshaft bearing bore (installed) ... 58.80 0.06 mm (2.315 .002 in.) Bore in block for camshaft bearings ... 65.100 0.025 mm (2.5630 .0010 in.)(3) Bore in block for main bearings (standard size) ... 96.926 0.013 mm (3.8160 .0005 in.) Bore in block for main bearings 0.51 mm (.020 in.) oversize ... 97.436 0.013 mm (3.8361 .0005 in.)(4) Dimension from center of main bearing bore to top of cylinder block (new) ... 383.515 0.165 mm (15.099 .0064 in.)(5) Dimension from center of main bearing bore to bottom of cylinder block (new) ... 153.99 0.10 mm (6.063 .004 in.)(6) Torque for bolts holding bearing caps for main bearings: a. Put 2P2506 Thread Lubricant on threads and washer face.b. Tighten all bolts to ... 41 4 N m (30 3 lb ft)c. Put a mark on each bolt and cap.d. Tighten all bolts from mark ... 90 5° Install bearing caps with the part number toward the front of the engine. Be sure that the mark (number) on the bearing cap next to the bolt hole is in agreement with the mark in the cylinder block.(7) Clearance between main bearing cap and cylinder block ... 0.033 mm (.0013 in.)tight to ... 0.043 mm (.0017 in.) loose Main bearing cap width ... 165.095 0.020 mm (6.4998 .0008 in.)Width of cylinder block for main bearing cap ... 165.100 0.018 mm (6.5000 .0007 in.) (8) Piston cooling orifice.

There are holes in the bores for the main bearings, between the cylinders for piston cooler orifices. These holes must have orifices (8) installed.

(9) Distance two dowels extend from the surface of the cylinder block ... 19.8 0.5 mm (.78 .02 in.)(10) Distance hollow dowel extends from the surface of the cylinder block ... 16.0 0.5 mm (.63 .02 in.)(11) Depth to install two dowels below the surface of the cylinder block (apply loctite #11358) ... 1.0 0.5 mm (.04 .02 in.)(12) Distance dowels extend from the front face of the cylinder block ... 22.4 0.5 mm (.88 .02 in.)(13) Distance stud extends from the front face of the cylinder block ... 15.7 0.5 mm (.62 .02 in.)(14) Distance two dowels extend from the rear face of the cylinder block ... 12.7 0.5 mm (.50 .02 in.)

There are holes in the bores for the main bearings, between the cylinders for piston cooler orifices. These holes must have orifices (8) installed.

(9) Distance two dowels extend from the surface of the cylinder block ... 19.8 0.5 mm (.78 .02 in.)(10) Distance hollow dowel extends from the surface of the cylinder block ... 16.0 0.5 mm (.63 .02 in.)(11) Depth to install two dowels below the surface of the cylinder block (apply loctite #11358) ... 1.0 0.5 mm (.04 .02 in.)(12) Distance dowels extend from the front face of the cylinder block ... 22.4 0.5 mm (.88 .02 in.)(13) Distance stud extends from the front face of the cylinder block ... 15.7 0.5 mm (.62 .02 in.)(14) Distance two dowels extend from the rear face of the cylinder block ... 12.7 0.5 mm (.50 .02 in.)