Information

ZEXEL

106671-3080

1066713080

HINO

221001113B

221001113b

Rating:

Service parts 106671-3080 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1024

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-3080

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-3080

1066713080

HINO

221001113B

221001113b

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0620

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.2

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

126

123

129

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

142.5

140.5

144.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.8

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

155

152

158

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

16

13

19

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

11+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

125

145

Fixing the lever

*

Timer adjustment

Pump speed

r/min

700+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

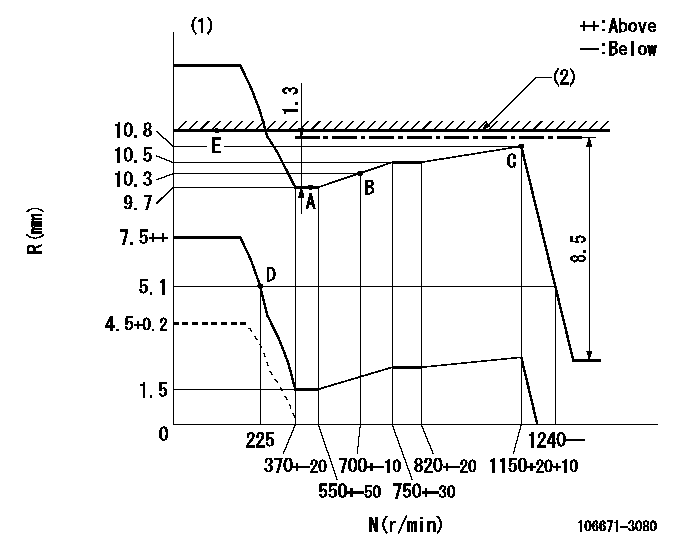

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)RACK LIMIT: RAL

----------

DL=4.8-0.2mm RAL=(11)mm

----------

----------

DL=4.8-0.2mm RAL=(11)mm

----------

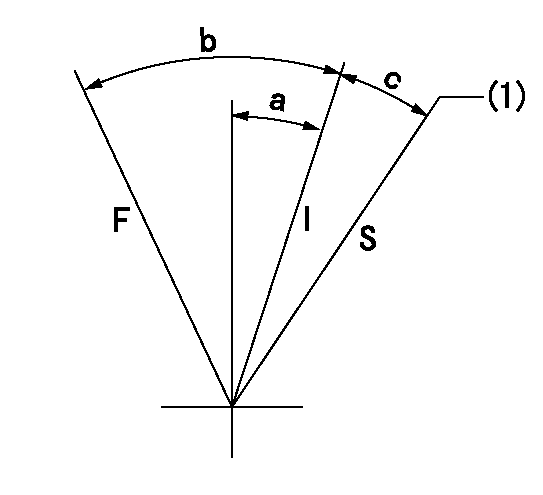

Speed control lever angle

F:Full speed

----------

----------

a=15deg+-5deg

----------

----------

a=15deg+-5deg

0000000901

F:Full load

I:Idle

S:Stop

(1)Set the load lever's stop position so that R = aa (N = 0).

----------

aa=4.5+0.2mm

----------

a=10deg+-5deg b=29deg+-3deg c=14deg+-3deg

----------

aa=4.5+0.2mm

----------

a=10deg+-5deg b=29deg+-3deg c=14deg+-3deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325-25r/min Ra=5.1mm

----------

----------

N1=325-25r/min Ra=5.1mm

----------

Information:

Below 0°C (32°F)

Ether is poisonous and flammable. Do not store replacement cylinders in living areas or in the operator's compartment.Do not smoke while changing ether cylinders.Use ether only in well ventilated areas.Use it with care to avoid fires.Keep the ether cylinders out of the reach of unauthorized persons.Avoid breathing of the vapors or repeated contact of ether with skin.Do not store cylinders in direct sunlight.Do not puncture or burn cylinders.Discard cylinders in a safe place.

Do not use excessive starting fluid during starting or after the engine is running. Engine damage can result. Do not crank the engine for more than 30 seconds. Allow 2 minutes for the starter to cool before cranking again.

Turn the battery disconnect switch (if equipped) OFF after the engine is stopped to prevent battery discharge, while starter motor is cooling.1. Repeat steps 1 through 4 in the "Above 0°C (32°F)" procedure.2. Try to start engine without ether. If it does not start, then use ether.3. While cranking the engine, spray starting fluid (ether) sparingly, into the engine air inlet or push the starting aid control switch and hold for three seconds (time required to fill chamber). Ether is injected when aid switch is released.Use additional starting fluid once every two seconds until engine runs smoothly.If oil pressure does not register within 15 seconds, stop the engine immediately to prevent damage.4. Do not apply load to the engine or increase engine speed until oil pressure and all temperature gauges reach operating temperature. Check all gauges during the warm-up period.For starting below -18°C (0°F), use of optional cold weather starting aids are recommended. A coolant heater or extra battery capacity may be required.Temperatures below -23°C (-10°F), consult your Caterpillar dealer or refer to the "Cold Weather Operation Guide," Form SEBU5338, available from your Caterpillar dealer.

Ether is poisonous and flammable. Do not store replacement cylinders in living areas or in the operator's compartment.Do not smoke while changing ether cylinders.Use ether only in well ventilated areas.Use it with care to avoid fires.Keep the ether cylinders out of the reach of unauthorized persons.Avoid breathing of the vapors or repeated contact of ether with skin.Do not store cylinders in direct sunlight.Do not puncture or burn cylinders.Discard cylinders in a safe place.

Do not use excessive starting fluid during starting or after the engine is running. Engine damage can result. Do not crank the engine for more than 30 seconds. Allow 2 minutes for the starter to cool before cranking again.

Turn the battery disconnect switch (if equipped) OFF after the engine is stopped to prevent battery discharge, while starter motor is cooling.1. Repeat steps 1 through 4 in the "Above 0°C (32°F)" procedure.2. Try to start engine without ether. If it does not start, then use ether.3. While cranking the engine, spray starting fluid (ether) sparingly, into the engine air inlet or push the starting aid control switch and hold for three seconds (time required to fill chamber). Ether is injected when aid switch is released.Use additional starting fluid once every two seconds until engine runs smoothly.If oil pressure does not register within 15 seconds, stop the engine immediately to prevent damage.4. Do not apply load to the engine or increase engine speed until oil pressure and all temperature gauges reach operating temperature. Check all gauges during the warm-up period.For starting below -18°C (0°F), use of optional cold weather starting aids are recommended. A coolant heater or extra battery capacity may be required.Temperatures below -23°C (-10°F), consult your Caterpillar dealer or refer to the "Cold Weather Operation Guide," Form SEBU5338, available from your Caterpillar dealer.