Information

ZEXEL

106661-0230

1066610230

NISSAN-DIESEL

1671796004

1671796004

Rating:

Cross reference number

ZEXEL

106661-0230

1066610230

NISSAN-DIESEL

1671796004

1671796004

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle

105015-3100

Nozzle holder

105031-4140

Opening pressure

MPa

22.6

Opening pressure

kgf/cm2

230

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-500

Outer diameter - inner diameter - length (mm) mm 6-2-500

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

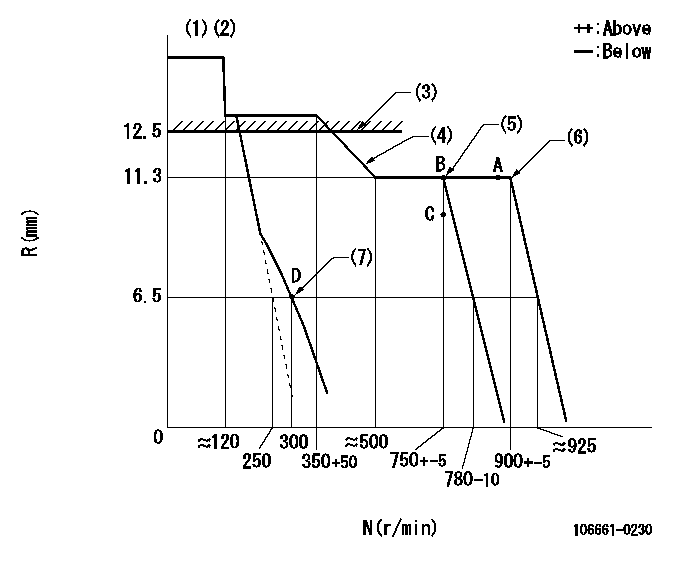

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

127

125

129

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

127

125

129

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

6.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

17

15.3

18.7

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.75

0.4

1.1

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.25

0.9

1.6

Timer adjustment_04

Pump speed

r/min

1100+50

Advance angle

deg.

2.5

1.9

2.7

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Confirm that the rack is pulled back to R = R1 or less at solenoid operation.

(3)RACK LIMIT: RAL

(4)Set the idle spring.

(5)Confirm speed droop.

(6)Set the maximum speed.

(7)Set idle sub-spring

----------

K=5 R1=4mm RAL=12.5+0.2mm

----------

----------

K=5 R1=4mm RAL=12.5+0.2mm

----------

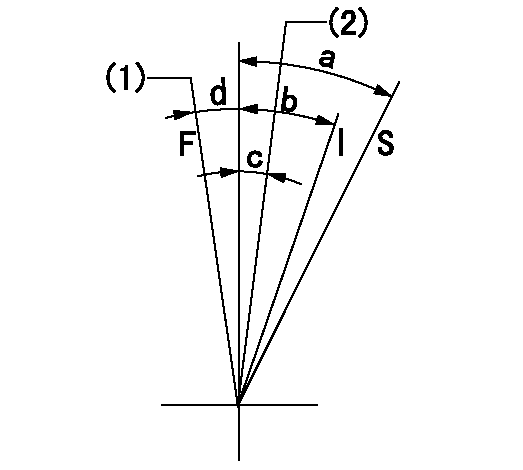

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Pump speed = aa

(2)Pump speed = bb

----------

aa=900r/min bb=750r/min

----------

a=(32deg) b=(27deg) c=(5deg) d=(3.5deg)

----------

aa=900r/min bb=750r/min

----------

a=(32deg) b=(27deg) c=(5deg) d=(3.5deg)

Information:

Illustration 1 g00293000

Junction Box-ETR Switchgear Required (OP, WT, OS)

(1) Electronic speed switch ("ESS").

(2) Lockwire (for seal screw plugs).

(3) Identification foil.

(4) Diode ("D4").

(5) Diode ("D3").

(6) Slave relay ("SR1").

(7) Slave relay ("SR2").

(8) Emergency stop switch ("ES").

(9) Circuit breakers.

Illustration 2 g00293001

Junction Box-ETS Switchgear Not Required (OP, WT, OS)

(1) Electronic speed switch ("ESS").

(2) Lockwire (for seal screw plugs).

(3) Identification foil.

(4) Slave relay ("SR1").

(5) Emergency stop switch ("ES").

(6) Time delay relay ("TD1").

(7) Start-stop switch ("SSS").

Illustration 3 g00293002

Junction Box-ETS Switchgear Required (OP, WT, OS)

(1) Electronic speed switch ("ESS").

(2) Lockwire (for seal screw plugs).

(3) Slave relay ("SR1").

(4) Emergency stop switch ("ES").

(5) Time delay relay ("TD1").

(6) Circuit breakers.

(7) Engine mounted start-stop switch ("EMSS."

Illustration 4 g00293003

Junction Box-ETS Switchgear Not Required (OP, WT)

(1) Time delay relay ("TD2").

(2) Emergency stop switch ("ES").

(3) Identification foil.

(4) Slave relay ("SR1").

(5) Slave relay ("SR2").

(6) Time delay relay ("TD1").

(7) Circuit breakers.

Illustration 5 g00293004

Junction Box With Start-stop Switch ("SSS")

(1) Emergency stop switch ("ES").

(2) Circuit breaker reset buttons.

(3) Start-stop switch ("SSS").

Illustration 6 g00293005

(1) Power distribution box. (2) Circuit breaker reset button.

Illustration 7 g00293006

(1) Hour meter.

Illustration 8 g00293007

(1) Air starting motor. (2) Air starting valve. (3) Air supply pipe.