Information

ZEXEL

101681-9580

1016819580

Rating:

Service parts 101681-9580 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}

15.

NOZZLE SET

Include in #1:

101681-9580

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

101681-9580

1016819580

Zexel num

Bosch num

Firm num

Name

101681-9580

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.2

2.15

2.25

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

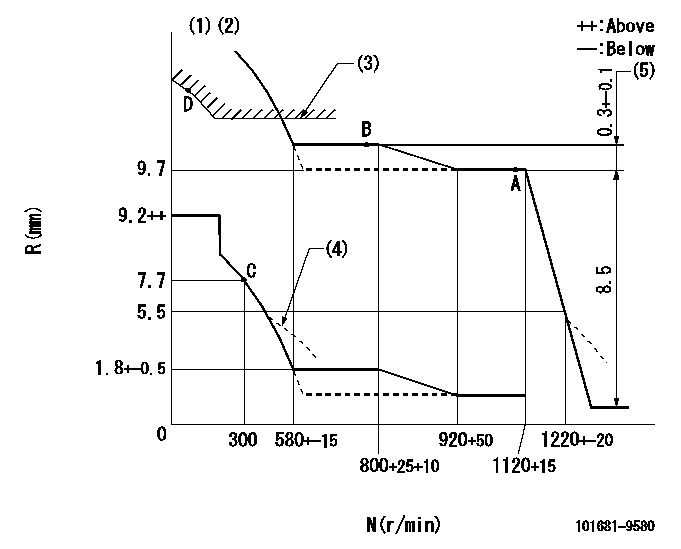

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

46

44.8

47.2

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

42

38.6

45.4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.7+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

9.4

8.1

10.7

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

65

55

75

Fixing the lever

*

Remarks

Startup boost setting

Startup boost setting

Timer adjustment

Pump speed

r/min

550--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

500

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

1

0.5

1.5

Timer adjustment_04

Pump speed

r/min

1100

Advance angle

deg.

2.7

2

3.4

Timer adjustment_05

Pump speed

r/min

1400

Advance angle

deg.

4.4

3.7

5.1

Timer adjustment_06

Pump speed

r/min

1500

Advance angle

deg.

4.8

4.1

5.5

Timer adjustment_07

Pump speed

r/min

-

Advance angle

deg.

6

6

6

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Excess fuel setting for starting: SXL

(4)Damper spring setting: DL

(5)Rack difference between N = N1 and N = N2

----------

RT=1 TH=2.3mm SXL=10.1+0.2mm DL=5.2-0.2mm N1=1100r/min N2=800r/min

----------

----------

RT=1 TH=2.3mm SXL=10.1+0.2mm DL=5.2-0.2mm N1=1100r/min N2=800r/min

----------

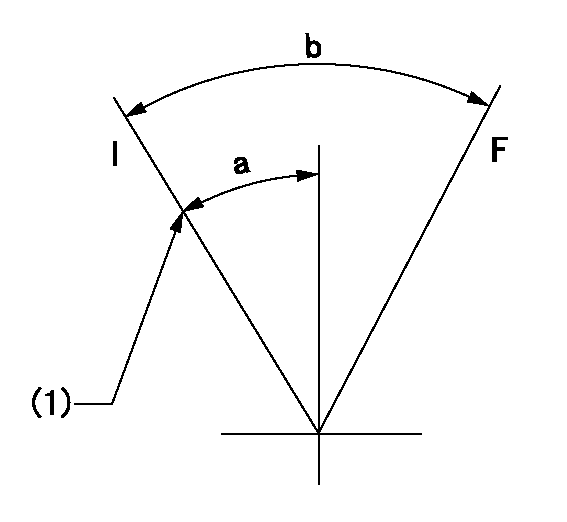

Speed control lever angle

F:Full speed

----------

----------

a=0deg+-5deg

----------

----------

a=0deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=16deg+-5deg b=30deg+-3deg

----------

----------

a=16deg+-5deg b=30deg+-3deg

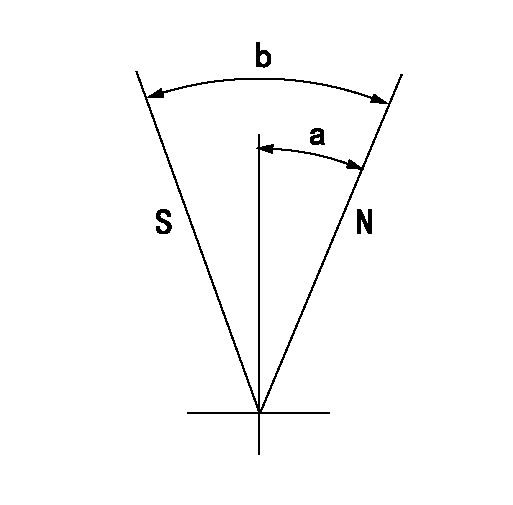

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=71deg+-5deg

----------

----------

a=20deg+-5deg b=71deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of gear's standard installation threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Safety is basically common sense. There are standard safety rules but each situation has its own peculiarities which cannot always be covered by rules. Your experience and common sense will be your best guide to safety. Be ever watchful for safety hazards and correct deficiencies promptly.Use the following safety precautions as a general guide to safe driving and maintenance practice. It is your responsibility to practice and promote safety. 1. Obey the rules of the road.2. Never adjust or repair engine or vehicle while it is in operation.3. Remove all tools and electrical cords before starting engine or operating vehicle.4. Keep work area clean.5. Store oily rags in containers.6. Store flammable liquids in a safe place away from the work area.7. Do not smoke around batteries. Hydrogen gas generated by charging is explosive. Keep batteries in a well ventilated area.8. Observe NO SMOKING signs.9. Do not wear loose clothing.10. Never operate an engine except in a well ventilated area.11. Do not exceed 30 PSI (2 kg/cm2) of air pressure when cleaning with air. Servicing cab-over truck engines require additional safety precautions as follows: Before Tilting Cab:1. Check clearance above and in front of truck cab.2. Keep tool chests and workbenches away from front of cab.3. Inspect sleeper and cab interior for loose luggage, tools and liquid containers which could fall forward.4. Check "Buddy" or "Jump" seats on right side of cab to be sure they are secured in place. While Tilting Cab1. Be sure the governor, transmission and clutch linkage do not interfere with the cab.2. Check position of steering shaft U-joint to prevent binding.

BEFORE TILTING CAB CHECK AREA FOR SUFFICIENT CLEARANCE AND OBSTRUCTIONS3. Never work under a partially tilted cab, unless it is properly secured.4. When cab is tilted past the over-center position, use cables or chains to prevent the cab from falling beyond the over-center point. Do not rely on cab hydraulic lift mechanism to retain or break the fall of the cab. While Cab is Tilted1. If it is necessary to open a door, take care to avoid damage to door hinges and/or window glass. While Lowering Cab1. Watch all governor, steering, clutch and transmission linkage. Bellcranks may turn over center, shift levers jam against bottom of cab and some models of clutch links separate when tilting cab. These clutch linkage components can miss their mating part when the cab is lowered.2. Be sure mating ends of exhaust and air cleaner inlet pipes align properly.3. Be sure cab lowers properly on mounting and locating pins. Twisted or misaligned cabs may miss locating pins and cab latch will not secure cab in locked position.4. Lock cab latching mechanism when cab is all the way down.

BEFORE TILTING CAB CHECK AREA FOR SUFFICIENT CLEARANCE AND OBSTRUCTIONS3. Never work under a partially tilted cab, unless it is properly secured.4. When cab is tilted past the over-center position, use cables or chains to prevent the cab from falling beyond the over-center point. Do not rely on cab hydraulic lift mechanism to retain or break the fall of the cab. While Cab is Tilted1. If it is necessary to open a door, take care to avoid damage to door hinges and/or window glass. While Lowering Cab1. Watch all governor, steering, clutch and transmission linkage. Bellcranks may turn over center, shift levers jam against bottom of cab and some models of clutch links separate when tilting cab. These clutch linkage components can miss their mating part when the cab is lowered.2. Be sure mating ends of exhaust and air cleaner inlet pipes align properly.3. Be sure cab lowers properly on mounting and locating pins. Twisted or misaligned cabs may miss locating pins and cab latch will not secure cab in locked position.4. Lock cab latching mechanism when cab is all the way down.

Have questions with 101681-9580?

Group cross 101681-9580 ZEXEL

Nissan-Diesel

101681-9580