Information

ZEXEL

101401-9070

1014019070

Rating:

Cross reference number

ZEXEL

101401-9070

1014019070

Zexel num

Bosch num

Firm num

Name

101401-9070

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 6-2-600

Outer diameter - inner diameter - length (mm) mm 6-2-600

Overflow valve

131424-6220

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

3.6

3.55

3.65

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.5 90.5

Cal 1-3 deg. 90 89.5 90.5

Difference between angles 2

Cal 1-4 deg. 180 179.5 180.5

Cal 1-4 deg. 180 179.5 180.5

Difference between angles 3

Cyl.1-2 deg. 270 269.5 270.5

Cyl.1-2 deg. 270 269.5 270.5

Injection quantity adjustment

Adjusting point

-

Rack position

10.2+-0.

5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46

45

47

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

-

Rack position

9.7+-0.5

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

10

8.7

11.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.2)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

46

45

47

Basic

*

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.3

Pump speed

r/min

1750

1750

1750

Average injection quantity

mm3/st.

60

56

64

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-0.

3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

37.7

33.7

41.7

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

D

Rack position

R2+0.4

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

30

26

34

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

67

67

72

Fixing the lever

*

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

R1-0.3

Boost pressure

kPa

20

18.7

21.3

Boost pressure

mmHg

150

140

160

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

R1(10.2)

Boost pressure

kPa

29.3

22.6

29.3

Boost pressure

mmHg

220

170

220

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

1750

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

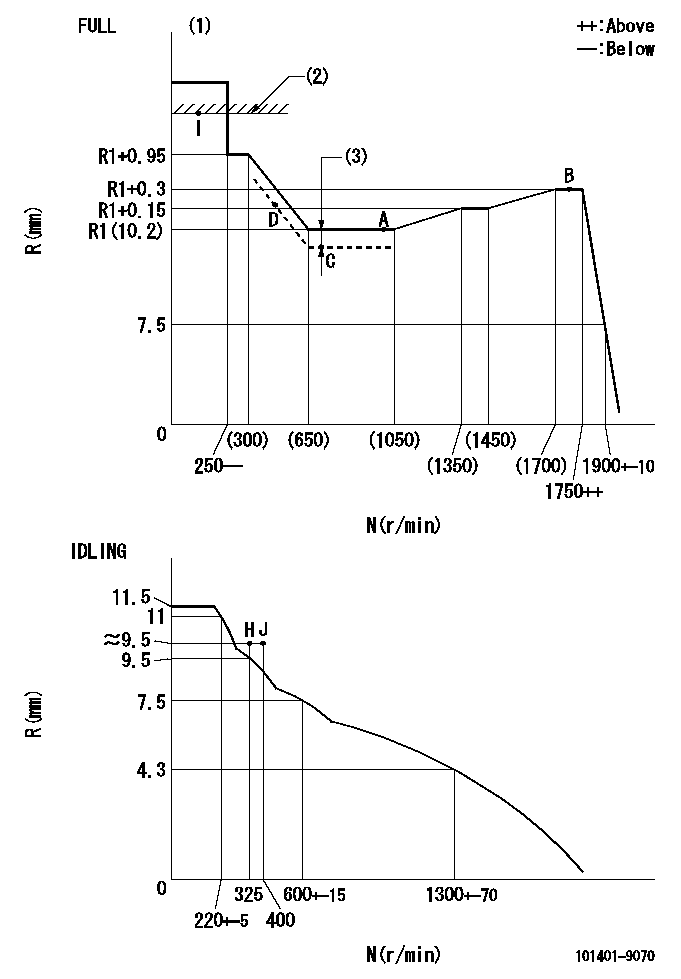

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

(3)Boost compensator stroke: BCL

----------

T1=B88 BCL=0.3+-0.1mm

----------

----------

T1=B88 BCL=0.3+-0.1mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=40mm

----------

a=26deg+-5deg b=42deg+-3deg

----------

aa=40mm

----------

a=26deg+-5deg b=42deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Free (at shipping)

(2)Use the hole at R = aa

(3)Rack position corresponding to bb

(4)Set the stopper bolt at speed = cc and rack position = dd.

(5)After setting the stopper bolt, confirm non-injection at speed ee. (Rack position = ff or less)

----------

aa=54mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=325r/min ff=8mm

----------

a=2deg+-5deg b=15deg+-5deg c=25deg+-5deg

----------

aa=54mm bb=16mm cc=1700r/min dd=6.5-0.5mm ee=325r/min ff=8mm

----------

a=2deg+-5deg b=15deg+-5deg c=25deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=950+-5r/min Ra=8mm

----------

----------

N1=950+-5r/min Ra=8mm

----------

Timing setting

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=11deg

----------

a=(130deg)

----------

aa=11deg

----------

a=(130deg)

Information:

Transmission Oil Cooler

The machine is equipped with a power shift transmission. A transmission oil cooler is installed in the outlet section of the radiator. The radiator coolant flows around the tubes of the cooler and cools the transmission oil as it flows through the cooler. The transmission oil then returns to the transmission inlet.Lubrication System

Oil Pump

(1) Strainer. (2) Oil pump relief valve. (3) Oil pump. (4) Idler gear. (5) Crankshaft gear.The lubrication system is the pressure type and the flow of oil goes from the oil pan through strainer (1) into oil pump (3). Oil pump (3) is driven by crankshaft gear (5) through the idler gear (4). The oil pump is connected to the front main bearing cap. Relief valve (2) which is spring loaded controls the maximum oil pressure. An oil pressure sending unit is connected to the main oil gallery.Oil under pressure goes from the oil pump through the relief valve, oil filter and into the main oil gallery that is a drilled passage the length of the crankcase. From the gallery the oil flows through drilled passages to the main bearing bores and then through the crankshaft passages to the big end (rod) bearings. The small end (rod) bearings, cylinder liners and pistons get splash lubrication from the big end (rod) bearings.The camshaft front bearing and journals are lubricated from numbers 1, 3 and 5 main bearings. The camshaft center journal supplies a controlled amount of oil to the rocker shaft assembly. Oil from the rocker shaft drains through a bleed hole in each rocker lever to lubricate the valves, guides, tappets (valve lifters) and cam lobes.

Timing Gears

(6) Idler gear. (7) Idler gear retainer plate.Oil also goes from the gallery through the rear of idler gear (6) hub, then through passages to lubricate the idler gear bearing and gear retainer plate (7). On engines equipped with hydraulic governed fuel injection pumps, the fuel pump adapter plate is also lubricated from the main oil gallery. The timing gears are splash lubricated from the idler gear hub.

Oil Lubrication SchematicAir Inlet And Exhaust System

Air Inlet Components

(1) Intake manifold. (2) Exhaust manifold.

Air Inlet Components

(3) Air cleaner.The air inlet and exhaust system components are: air cleaner (3), intake manifold (1), an air inlet hose, an air indicator, the cylinder head valves and valve mechanism components, exhaust manifold (2), pipe and muffler.Air is pulled in the air inlet system by the intake stroke of the piston. The air flows in air cleaner (3), through air inlet hose that directs the volume of air to intake manifold (1). The air flows through intake manifold (1) which directs even distribution of the air to each cylinder where the air is mixed with fuel from the injectors. The sequence and action of the engines' four cylinders and four strokes, (compression, power, exhaust and intake) give constant air flow to the intake system for engine operation.An air indicator located on the air inlet hose shows a red indication when too much air restriction (dirt)

The machine is equipped with a power shift transmission. A transmission oil cooler is installed in the outlet section of the radiator. The radiator coolant flows around the tubes of the cooler and cools the transmission oil as it flows through the cooler. The transmission oil then returns to the transmission inlet.Lubrication System

Oil Pump

(1) Strainer. (2) Oil pump relief valve. (3) Oil pump. (4) Idler gear. (5) Crankshaft gear.The lubrication system is the pressure type and the flow of oil goes from the oil pan through strainer (1) into oil pump (3). Oil pump (3) is driven by crankshaft gear (5) through the idler gear (4). The oil pump is connected to the front main bearing cap. Relief valve (2) which is spring loaded controls the maximum oil pressure. An oil pressure sending unit is connected to the main oil gallery.Oil under pressure goes from the oil pump through the relief valve, oil filter and into the main oil gallery that is a drilled passage the length of the crankcase. From the gallery the oil flows through drilled passages to the main bearing bores and then through the crankshaft passages to the big end (rod) bearings. The small end (rod) bearings, cylinder liners and pistons get splash lubrication from the big end (rod) bearings.The camshaft front bearing and journals are lubricated from numbers 1, 3 and 5 main bearings. The camshaft center journal supplies a controlled amount of oil to the rocker shaft assembly. Oil from the rocker shaft drains through a bleed hole in each rocker lever to lubricate the valves, guides, tappets (valve lifters) and cam lobes.

Timing Gears

(6) Idler gear. (7) Idler gear retainer plate.Oil also goes from the gallery through the rear of idler gear (6) hub, then through passages to lubricate the idler gear bearing and gear retainer plate (7). On engines equipped with hydraulic governed fuel injection pumps, the fuel pump adapter plate is also lubricated from the main oil gallery. The timing gears are splash lubricated from the idler gear hub.

Oil Lubrication SchematicAir Inlet And Exhaust System

Air Inlet Components

(1) Intake manifold. (2) Exhaust manifold.

Air Inlet Components

(3) Air cleaner.The air inlet and exhaust system components are: air cleaner (3), intake manifold (1), an air inlet hose, an air indicator, the cylinder head valves and valve mechanism components, exhaust manifold (2), pipe and muffler.Air is pulled in the air inlet system by the intake stroke of the piston. The air flows in air cleaner (3), through air inlet hose that directs the volume of air to intake manifold (1). The air flows through intake manifold (1) which directs even distribution of the air to each cylinder where the air is mixed with fuel from the injectors. The sequence and action of the engines' four cylinders and four strokes, (compression, power, exhaust and intake) give constant air flow to the intake system for engine operation.An air indicator located on the air inlet hose shows a red indication when too much air restriction (dirt)

Have questions with 101401-9070?

Group cross 101401-9070 ZEXEL

Mazda

Mazda

Mazda

Mazda

Mazda

Mitsubishi-Heav

Dpico

101401-9070