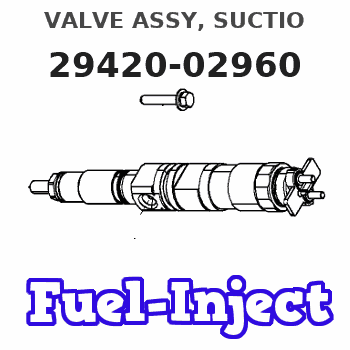

Information valve assy, suctio

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Common Rail Parts Fuel metering Solenoid Control Valve 294200-2960 for Mitsubishi ISF3.8 FAW CA4DD 1460A062

Generic 294000-0992 / 2940000992 || 294000-1630 / 2940001630 || 294000-1700 / 2940001700 || 294000-2030 / 2940002030 || 294000-2330 / 2940002330

Generic 294000-0992 / 2940000992 || 294000-1630 / 2940001630 || 294000-1700 / 2940001700 || 294000-2030 / 2940002030 || 294000-2330 / 2940002330

1pc/Package Fuel Pressure Control Valve 294200-2960 2942002960 YANGMO-AUTO

YANGMO-AUTO OEM NUMBER 294200-2960 2942002960 || In oder to confirm the parts fitment, you may send VIN or parts number to us || Simply remove and Easy to install || Excellent performance || YANGM-AUTO

YANGMO-AUTO OEM NUMBER 294200-2960 2942002960 || In oder to confirm the parts fitment, you may send VIN or parts number to us || Simply remove and Easy to install || Excellent performance || YANGM-AUTO

Parts Number 294200-2960 2942002960 Fuel Pressure Control Valve Pack of 1 Piece

CAIJUN-AUTO PARTS NUMBER: 294200-2960 2942002960 || You can send VIN to us if you are not sure about your OEM number || If you have any questions, please be free to contact us at any time || Durable materials with high performance || Enjoy your shopping from CAIJUN-AUTO

CAIJUN-AUTO PARTS NUMBER: 294200-2960 2942002960 || You can send VIN to us if you are not sure about your OEM number || If you have any questions, please be free to contact us at any time || Durable materials with high performance || Enjoy your shopping from CAIJUN-AUTO

You can express buy:

USD 59.71

19-05-2025

19-05-2025

294200-2960 Fuel Pump Regulator Suction Control SCV Valve For Mitsubishi Triton Lancer Mirage 4N13 4N15 Pajero 4N14 Cummins

USD 76.42

19-05-2025

19-05-2025

1460A062 Pressure Regulator Suction Control Valve For Mitsubishi Triton Lancer Mirage CUMMINS ISF3.8 FAW CA4DD 146 294200-2960

Images:

USD 51.9

[13-May-2025]

USD 34.28

[13-May-2025]

USD 33.22

[13-May-2025]

USD 33

[13-May-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29420-02960 | VALVE ASSY, SUCTIO |

Information:

Table 1

Part Number Container Size Volume of Finished Coolant Produced

351-9431 3.8 L (1 US gal) 50.5 L (13.3 US gal)

351-9432 20 L (5.3 US gal) 267 L (70.5 US gal)

351-9433 208 L (55 US gal) 2773 L (733 US gal)

366-2753 (1) 1000 L (264 US gal) 13333 L (3523 US gal)

(1) NACD and LACD onlyMixing Cat ELI

The recommended water for mixing with Cat ELI concentrate is distilled or deionized water. Water must meet requirements of ASTM 1193, "Type IV Reagent Water Specification". If distilled or deionized water is not available, water should meet the “Caterpillar Minimum Acceptable Water Requirements” provided in this Special Publication.To ensure a proper concentration, the preferred method is to mix Cat ELI concentrate with water. Then, add the mixed coolant to the engine cooling system. Add the proper amounts of water and Cat ELI into a clean container and mix thoroughly by manual stirring or mechanical agitation.If the preferred method cannot be performed, a Cat ELI mixture can be made by adding Cat ELI concentrate directly into engine cooling system. Add good quality water until the dilution level is approximately 7.5%. Adequate mixing is attained by operating the engine for at least 30 minutes.Appropriate mixing rates for available ELI container sizes are provided in Table 1.After the addition of water and proper mixing, the concentration of Cat ELI can be determined using the 360-0774 Digital Brix Refractometer.Changing to Cat ELI

For cooling systems previously running Cat ELC or an extended life coolant that meets Cat EC-1 requirements, drain the cooling system and flush with water. Then refill the cooling system with a mixture of 7.5% Cat ELI in water that meets the “Caterpillar Minimum Acceptable Water Requirements”.For cooling systems previously running a conventional heavy-duty coolant or a water/SCA mixture, follow the steps listed in this Special Publication, "Changing to Cat ELC". Then refill the cooling system with a mixture of 7.5% Cat ELI in water that meets the “Caterpillar Minimum Acceptable Water Requirements”.Cat ELI Maintenance

Maintenance of Cat ELI is similar to Cat ELC. A coolant sample should be submitted for S O S Level 2 Coolant Analysis after the first 500 hours of operation and then annually thereafter.Cat ELC Extender should be added at the midpoint of service life (typically 6,000 hours), or as recommended by S O S Coolant Analysis results.Analysis and interpretation of Cat ELI S O S results is similar to the analysis and interpretation of Cat ELC. There will be no glycol and glycol oxidation products, which do not apply to Cat ELI.The concentration of a sample of in-use Cat ELI taken from the cooling system can also be determined using the 360-0774 Digital Brix Refractometer.Note: Clean water is the only flushing agent that is required when Cat ELI is drained from a properly maintained cooling system.Mixing Cat ELI and Cat ELC

Since Cat ELI and Cat ELC are based on the same corrosion inhibitor technology, Cat ELI can be mixed with Cat