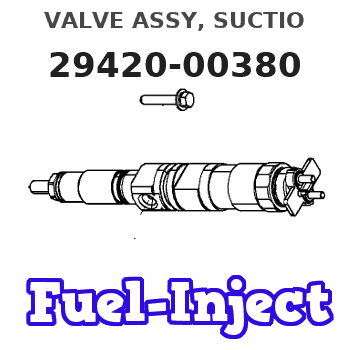

Information valve assy, suctio

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Compatible with 294200-0380 Fuel Pump Regulator SCV Suction Control Valve Fit For RAV4 Fit For John Fit For Deere Tractor S450 Industrial L6 Fit For Hino Fit For Isuzu 6HK1 Car accessories

HSZLYRWQM 1,Fuel injection fuel rail pressure sensor has excellent corrosion resistance, improve high mechanical strength, can work reliably for a long time under high pressure and harsh environments to ensure smooth operation and prolong the engine life. || 2,Replacing a new fuel pressure sensor can solve problems such as weak acceleration, difficulty starting, and abnormal shaking during driving caused by sensor failures. || 3, The fuel Rail Pressure Sensor is made of high-quality raw materials, with stable performance, can effectively detect pressure and transmit data, and has a long service life. || 4,Direct-fit OE replacement ensures ease of installation. Designed and manufactured to stringent quality standards at a certified facility, so you can install with confidence. || 5,Please check the part number when purchasing to facilitate matching with your vehicle.

HSZLYRWQM 1,Fuel injection fuel rail pressure sensor has excellent corrosion resistance, improve high mechanical strength, can work reliably for a long time under high pressure and harsh environments to ensure smooth operation and prolong the engine life. || 2,Replacing a new fuel pressure sensor can solve problems such as weak acceleration, difficulty starting, and abnormal shaking during driving caused by sensor failures. || 3, The fuel Rail Pressure Sensor is made of high-quality raw materials, with stable performance, can effectively detect pressure and transmit data, and has a long service life. || 4,Direct-fit OE replacement ensures ease of installation. Designed and manufactured to stringent quality standards at a certified facility, so you can install with confidence. || 5,Please check the part number when purchasing to facilitate matching with your vehicle.

Compatible with 294200-0380 294200-0180 Fuel Pump Regulator SCV Suction Control Valve Fit For RAV4 Fit For John Fit For Deere Tractor S450 Fit For Hino Fit For Isuzu 6HK1 Car accessories

HSZLYRWQM 1,Fuel injection fuel rail pressure sensor has excellent corrosion resistance, improve high mechanical strength, can work reliably for a long time under high pressure and harsh environments to ensure smooth operation and prolong the engine life. || 2,Replacing a new fuel pressure sensor can solve problems such as weak acceleration, difficulty starting, and abnormal shaking during driving caused by sensor failures. || 3, The fuel Rail Pressure Sensor is made of high-quality raw materials, with stable performance, can effectively detect pressure and transmit data, and has a long service life. || 4,Direct-fit OE replacement ensures ease of installation. Designed and manufactured to stringent quality standards at a certified facility, so you can install with confidence. || 5,Please check the part number when purchasing to facilitate matching with your vehicle.

HSZLYRWQM 1,Fuel injection fuel rail pressure sensor has excellent corrosion resistance, improve high mechanical strength, can work reliably for a long time under high pressure and harsh environments to ensure smooth operation and prolong the engine life. || 2,Replacing a new fuel pressure sensor can solve problems such as weak acceleration, difficulty starting, and abnormal shaking during driving caused by sensor failures. || 3, The fuel Rail Pressure Sensor is made of high-quality raw materials, with stable performance, can effectively detect pressure and transmit data, and has a long service life. || 4,Direct-fit OE replacement ensures ease of installation. Designed and manufactured to stringent quality standards at a certified facility, so you can install with confidence. || 5,Please check the part number when purchasing to facilitate matching with your vehicle.

High Pressure Pump Suction Control Valve SCV 294200-0360 294200-0260 294200-0160 294200-0300 294200-0380 294200-0190 2942000170(294009-0260)

KONGLIE High pressure pump suction control valve for various applications || Compatible with SCV 294200-0360, 294200-0260, 294200-0160, 294200-0300, 294200-0380, 294200-0190, 2942000170 || Made with high-quality materials for durability and reliability || Easy to install and replace,Improves the performance and efficiency of the pump || High Pressure Pump Suction Control Valve SCV 294200-0360 294200-0260 294200-0160 294200-0300 294200-0380 294200-0190 2942000170

KONGLIE High pressure pump suction control valve for various applications || Compatible with SCV 294200-0360, 294200-0260, 294200-0160, 294200-0300, 294200-0380, 294200-0190, 2942000170 || Made with high-quality materials for durability and reliability || Easy to install and replace,Improves the performance and efficiency of the pump || High Pressure Pump Suction Control Valve SCV 294200-0360 294200-0260 294200-0160 294200-0300 294200-0380 294200-0190 2942000170

You can express buy:

USD 25

14-06-2025

14-06-2025

New Pressure Regulator Suction Control Valve Fuel Common Rail Metering Unit for HINO Inustrial ISUZU 294200-0390 294200-0380

Images:

USD 146.74

[14-Jun-2025]

USD 62.96

[14-Jun-2025]

USD 16.99

[13-May-2025]

USD 23.56

[13-May-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29420-00380 | VALVE ASSY, SUCTIO |

Information:

Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Engine Air Cleaner - Check indicator, clean and replace elements, if necessary Air-to-Air Aftercooler System - Check, clean if necessaryPM Level 1

Every 2,000 gal (7580 L) of Fuel or 12,500 Miles (20 000 km) or 250 Hours* Scheduled Oil Sampling (S O S) Analysis -Obtain Engine Oil and Filter(s)2 - Replace 3 Fuel Filters - Replace final filter and Clean/Replace primary filter (if equipped) 3 Cooling System - Test for concentration/Add coolant additive or Replace supplemental additive element (if equipped) Crankcase Breather - Clean Alternator, Fan and Accessory Drive Belts -Inspect/Replace Hoses and Clamps - Inspect/Replace Air-to-Air Aftercooler System - Inspect/Check Cylinder Head Grounding Stud -Inspect/Clean/Tighten Engine Valve Lash (at Initial PM 1 Interval) -Check/Adjust Radiator Fins - Inspect/CheckPM Level 2

Every 26,600 gal (100 000 L) of Fuel or 166,000 Miles (267 250 km) or 3,330 Hours* Performance Analysis Report (PAR) - Obtain Engine - Steam clean Thermostat - Replace Cooling System - Clean/Flush Water Pump - Rebuild or Exchange Electronic Unit Injectors - Test Engine Valve Lash and Electronic Unit Injector Preload - Check/Adjust Jacobs Brake Slave Lash - Check/AdjustPM Level 3

Every 40,000 gal (151 600 L) of Fuel or 250,000 Miles (402 500 km) or 5,000 Hours* Air Compressor - Rebuild or Exchange Turbocharger - Rebuild or Exchange Engine Mounts - Inspect/Check Throttle Position Sensor - Check/Adjust calibrationOverhaul

Every 80,000 gal (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Hours* Overhaul Information Cylinder Head Assembly - Rebuild or Exchange Cylinder Packs - Exchange Spacer Block - Inspect Camshaft Followers - Inspect Oil Pump and Fuel Transfer Pump - Inspect Thrust, Main and Rod Bearings - Replace Valve Rotators - Replace Thermostat - Replace Throttle Position Sensor - Replace Crankshaft - Inspect Camshaft - Inspect Vibration Damper - Inspect Electronic Unit Injectors - Test Oil Cooler and Air-to-Air Aftercooler Core -Clean/Test*First Perform Previous Service Hour Items2Remote mounted or auxiliary filters require additional oil. When changing oil, overfill crankcase by amount needed for auxiliary system (if equipped).3To prevent crankshaft and/or bearing damage, crank engine to fill all filters before starting engine.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Engine Air Cleaner - Check indicator, clean and replace elements, if necessary Air-to-Air Aftercooler System - Check, clean if necessaryPM Level 1

Every 2,000 gal (7580 L) of Fuel or 12,500 Miles (20 000 km) or 250 Hours* Scheduled Oil Sampling (S O S) Analysis -Obtain Engine Oil and Filter(s)2 - Replace 3 Fuel Filters - Replace final filter and Clean/Replace primary filter (if equipped) 3 Cooling System - Test for concentration/Add coolant additive or Replace supplemental additive element (if equipped) Crankcase Breather - Clean Alternator, Fan and Accessory Drive Belts -Inspect/Replace Hoses and Clamps - Inspect/Replace Air-to-Air Aftercooler System - Inspect/Check Cylinder Head Grounding Stud -Inspect/Clean/Tighten Engine Valve Lash (at Initial PM 1 Interval) -Check/Adjust Radiator Fins - Inspect/CheckPM Level 2

Every 26,600 gal (100 000 L) of Fuel or 166,000 Miles (267 250 km) or 3,330 Hours* Performance Analysis Report (PAR) - Obtain Engine - Steam clean Thermostat - Replace Cooling System - Clean/Flush Water Pump - Rebuild or Exchange Electronic Unit Injectors - Test Engine Valve Lash and Electronic Unit Injector Preload - Check/Adjust Jacobs Brake Slave Lash - Check/AdjustPM Level 3

Every 40,000 gal (151 600 L) of Fuel or 250,000 Miles (402 500 km) or 5,000 Hours* Air Compressor - Rebuild or Exchange Turbocharger - Rebuild or Exchange Engine Mounts - Inspect/Check Throttle Position Sensor - Check/Adjust calibrationOverhaul

Every 80,000 gal (303 200 L) of Fuel or 500,000 Miles (805 000 km) or 10,000 Hours* Overhaul Information Cylinder Head Assembly - Rebuild or Exchange Cylinder Packs - Exchange Spacer Block - Inspect Camshaft Followers - Inspect Oil Pump and Fuel Transfer Pump - Inspect Thrust, Main and Rod Bearings - Replace Valve Rotators - Replace Thermostat - Replace Throttle Position Sensor - Replace Crankshaft - Inspect Camshaft - Inspect Vibration Damper - Inspect Electronic Unit Injectors - Test Oil Cooler and Air-to-Air Aftercooler Core -Clean/Test*First Perform Previous Service Hour Items2Remote mounted or auxiliary filters require additional oil. When changing oil, overfill crankcase by amount needed for auxiliary system (if equipped).3To prevent crankshaft and/or bearing damage, crank engine to fill all filters before starting engine.