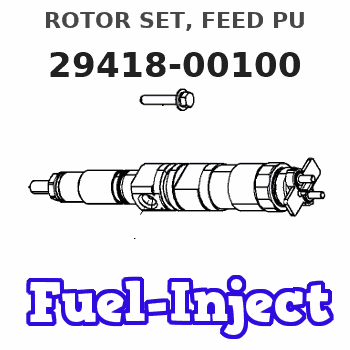

Information rotor set, feed pu

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

294180-0080, 294180-0090, 294180-0100, 294180-0110, 294180-0010 Feed Pump Rotor Set Gear Pump ,Compatible For HP3/HP4 Fuel Pump(294180-0100)

Sdvbfjnm High-quality replacement rotor set ,Compatible For HP3 and HP4 fuel pumps. || Durable construction ensures long-lasting performance and reliability in demanding conditions. || Easy installation process saves time and effort, making it suitable for both professionals and DIY enthusiasts. || Optimized for efficient fuel delivery, enhancing the overall performance of your fuel pump system. || Compatible with multiple models, providing versatility for various automotive applications.

Sdvbfjnm High-quality replacement rotor set ,Compatible For HP3 and HP4 fuel pumps. || Durable construction ensures long-lasting performance and reliability in demanding conditions. || Easy installation process saves time and effort, making it suitable for both professionals and DIY enthusiasts. || Optimized for efficient fuel delivery, enhancing the overall performance of your fuel pump system. || Compatible with multiple models, providing versatility for various automotive applications.

294180-0100 Pump Gear Rotor for HP3/HP4 Common Rail Pump 294000-1401

xinDieseltt Suitable for HP3/HP4 294000-1401 Common Rail Pump || Check whether the part number is correct to avoid installing incorrect parts || Our gear comes with six-month warranty || Every pump rotor is rigorously tested and verified || If you are unsure if it will fit your vehicle or have problems with installation, please contact our customer service staff to assist you

xinDieseltt Suitable for HP3/HP4 294000-1401 Common Rail Pump || Check whether the part number is correct to avoid installing incorrect parts || Our gear comes with six-month warranty || Every pump rotor is rigorously tested and verified || If you are unsure if it will fit your vehicle or have problems with installation, please contact our customer service staff to assist you

You can express buy:

USD 17.29

29-05-2025

29-05-2025

294180-0080 HP3 HP4 Common Rail Pump Rotor Set 2941800080 Feed Pump China made all new 294180-0100

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29418-00100 | S-M | ROTOR SET, FEED PU | |

| S-M | ISUZU | ROTOR SET, FEED PU | |

| SM | MITSUBISHI | ROTOR SET, FEED PU |

Information:

Illustration 1 g00569647

ETR Junction Box with oil pressure protection (OP), water temperature protection (WT), and overspeed protection (OS) that does not require a switchgear for use on 3200 through 3400 Engines

(1) Terminal strips (TS)

(2) Wiring harness

(3) Electronic speed switch (ESS)

(4) Junction box

(5) Identification foil

(6) Jumper between terminals (TS-3) and (TS-4)

(7) Diodes (D3) and (D4)

(8) Emergency stop switch (ES)

(9) Jumper between terminals (TS-28) and (TS-29)

(10) Jumper between terminals (TS-30) and (TS-31)

(11) Slave relay (SR1)

(12) Slave relay (SR2) for air shutoff solenoid (ASOS)

(13) Grommets for engine oil pressure switches

(14) Start/stop switch (SSS)

(15) Circuit breakers

(16) Engine oil pressure switch (OPS1)

(17) Mounting brackets for grommets

Illustration 2 g00290419

ETR Junction Box with oil pressure protection (OP), water temperature protection (WT), and overspeed protection (OS) that does not require a switchgear for use on 3500 Engines

(1) Terminal strips (TS)

(2) Wiring harness

(3) Electronic speed switch (ESS)

(4) Junction box

(5) Identification foil

(6) Jumper between terminals (TS-3) and (TS-4)

(7) Diodes (D3) and (D4)

(8) Emergency stop switch (ES)

(9) Jumper between terminals (TS-27) and (TS-28)

(10) Jumper between terminals (TS-28) and (TS-29)

(11) Jumper between terminals (TS-30) and (TS-31)

(12) Diode for electric governor actuator (if equipped)

(13) Slave relay (SR1)

(14) Slave relay (SR2) for air shutoff solenoid (ASOS)

(15) Slave relay (SR3) for starting aid switch (if equipped)

(16) Grommets for engine oil pressure switches

(17) Start/stop switch (SSS)

(18) Circuit breakers

(19) Engine oil pressure switch (OPS1)

(20) Mounting brackets for grommets

(21) Engine oil pressure switch (OPS2) (if equipped) Introduction

The ETR Junction Box with oil pressure protection (OP), water temperature protection (WT), and overspeed protection (OS) that does not require a switchgear is a system that has full protection. The system has a junction box arrangement that is designed to monitor four functions:

Engine overspeed

Crank termination

Oil pressure

Coolant temperatureThe junction box includes the following components:

Electronic speed switch (ESS) (3)

Start/stop switch (SSS) (17) and (14)

Slave relay (SR1) (11) and (13)

Slave relay (SR2) (if equipped) with an air shutoff solenoid (ASOS) (12) and (14)

Oil pressure switch (OPS1) (16) and (19)

Oil pressure switch (OPS2) that is only in 3500 Engines (21)

Emergency stop switch (ES) (8)The components that are listed below operate with the junction box. The components are also mounted on the engine.

Fuel shutoff solenoid (FSOS)

Air shutoff solenoid (ASOS)

Water temperature switch (WTS)The slave relay (SR1) must be energized in order for the engine to run with the ETR electric protection system.Electrical Schematics and Wiring Diagrams

This manual contains the point-to-point wiring diagrams for the complete electric protection system and the junction box. Four types of electrical schematics for each electric protection system arrangement are shown in this service manual.

Junction box wiring diagram

IEC (International Electro-Technical Commission) schematic

JIC (Joint Industrial Council) schematic

Junction box wiring harness diagramNote: The line number that follows a component code gives the location of the component on the IEC and JIC schematics.Circuit Operation With No Faults

Engine Shutdown

When the engine is stopped, power is always available across the terminals (ESS-5) and (ESS-6) (line 54) of the electronic speed switch (ESS). All of the switches are in the normally open position or the normally closed positions at that time.Engine Start-up

Illustration 3 g00282721

2W-6832 Switch

(1) Keyway.

Table 1

Switch Position Contacts that