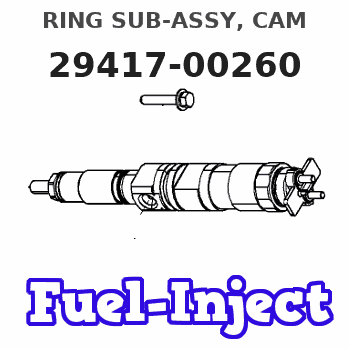

Information ring sub-assy, cam

Rating:

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29417-00260 | SM | RING SUB-ASSY, CAM | |

| SM | MITSUBISHI | RING SUB-ASSY, CAM |

Information:

Introduction

The information in the Testing and Adjusting is a supplement to the Troubleshooting section of this Service Manual. The Troubleshooting section references several procedures in the Testing and Adjusting. The references are made when more detailed information is necessary in order to complete the diagnosis, the calibration, or the testing of a component.The Abbreviations and Symbols section contains the following items that are used in the wiring drawings for the ETR electric protection system and the ETS electric protection system.

Abbreviations

Symbols

Wiring sizes

Wiring color

Number codesThe section for the junction box arrangements contains the four types of electrical diagrams and the schematics that are listed below in order to describe each arrangement of the electric protection system.

Junction box wiring diagram

IEC (International Electro-Technical Commission) schematic

JIC (Joint Industrial Council) schematic

Diagram for the wiring harness in the junction box

Table 1

Speed Specification Chart

Engine Model No. of flywheel teeth Typical Rated Engine Speeds Functions of the Electronic Speed Switch(1)

Rated Engine RPM Magnetic Pickup(2)

Frequency (+ 25 hz)

Note C Overspeed Setting

(+ 25 rpm)

Note A 75% Overspeed Verify

(+ 25 rpm)

Note B Crank Termination Setting (rpm) Oil Step Setting (rpm)

3200 126 2600

2800 5460

5880 3068

3304 2301

2478 400 1325

134 1500

1800

2000

2200 3550

4020

4667

4913 1770

2124

2360

2596 1328

1593

1770

1947 400 1325

2400

2500

2600

2800 5360

5583

5807

6253 2832

2950

3068

3304 2124

2213

2301

2478

3300 130 2200 4767 2596 1947 400 1250

132 1400

1500

1800

2200 3080

3300

3960

4840 1652

1770

2124

2596 1239

1328

1593

1947 400 1125

156 1400

1500

1800 3640

3900

4680 1652

1770

2124 1239

1328

1593 400 1125

2000

2100

2200 5200

5460

5720 2360

2478

2596 1770

1859

1947 1250

3400 113 1000

1200

1300 1883

2260

2448 1180

1416

1534 885

1062

1151 400 750

1500

1600 2825

3013 1770

1888 1328

1416 1350

1750

1800 3296

3390 2065

2124 1549

1593 1125

1900

2100 3578

3955 2242

2478 1682

1859 1250

136 1000

1200 2267

2720 1180

1416 885

1062 400 750

1500 3400 1770 1328 1125

1800

2100 4080

4760 2124

2478 1593

1859 1350

343

346

348

349 140 1000

1200 2333

2800 1180

1416 885

1062 400 750

151 1500

1800 3775

4530 1770

2124 1328

1593 400 1200

342 151 1000

1200 2517

3020 1180

1416 885

1062 400 800

353

379

398

399 151 1000

1200 2517

3020 1180

1416 885

1062 400 800

183 1000

1200 3050

3660 1180

1416 885

1062 400 800

3500 151 1000

1200

1500

1800 2517

3020

3775

4530 1180

1416

1770

2124 885

1062

1328

1593 400 800

183 1000

1200 3050

3660 1180

1416 885

1062&nbs

The information in the Testing and Adjusting is a supplement to the Troubleshooting section of this Service Manual. The Troubleshooting section references several procedures in the Testing and Adjusting. The references are made when more detailed information is necessary in order to complete the diagnosis, the calibration, or the testing of a component.The Abbreviations and Symbols section contains the following items that are used in the wiring drawings for the ETR electric protection system and the ETS electric protection system.

Abbreviations

Symbols

Wiring sizes

Wiring color

Number codesThe section for the junction box arrangements contains the four types of electrical diagrams and the schematics that are listed below in order to describe each arrangement of the electric protection system.

Junction box wiring diagram

IEC (International Electro-Technical Commission) schematic

JIC (Joint Industrial Council) schematic

Diagram for the wiring harness in the junction box

Table 1

Speed Specification Chart

Engine Model No. of flywheel teeth Typical Rated Engine Speeds Functions of the Electronic Speed Switch(1)

Rated Engine RPM Magnetic Pickup(2)

Frequency (+ 25 hz)

Note C Overspeed Setting

(+ 25 rpm)

Note A 75% Overspeed Verify

(+ 25 rpm)

Note B Crank Termination Setting (rpm) Oil Step Setting (rpm)

3200 126 2600

2800 5460

5880 3068

3304 2301

2478 400 1325

134 1500

1800

2000

2200 3550

4020

4667

4913 1770

2124

2360

2596 1328

1593

1770

1947 400 1325

2400

2500

2600

2800 5360

5583

5807

6253 2832

2950

3068

3304 2124

2213

2301

2478

3300 130 2200 4767 2596 1947 400 1250

132 1400

1500

1800

2200 3080

3300

3960

4840 1652

1770

2124

2596 1239

1328

1593

1947 400 1125

156 1400

1500

1800 3640

3900

4680 1652

1770

2124 1239

1328

1593 400 1125

2000

2100

2200 5200

5460

5720 2360

2478

2596 1770

1859

1947 1250

3400 113 1000

1200

1300 1883

2260

2448 1180

1416

1534 885

1062

1151 400 750

1500

1600 2825

3013 1770

1888 1328

1416 1350

1750

1800 3296

3390 2065

2124 1549

1593 1125

1900

2100 3578

3955 2242

2478 1682

1859 1250

136 1000

1200 2267

2720 1180

1416 885

1062 400 750

1500 3400 1770 1328 1125

1800

2100 4080

4760 2124

2478 1593

1859 1350

343

346

348

349 140 1000

1200 2333

2800 1180

1416 885

1062 400 750

151 1500

1800 3775

4530 1770

2124 1328

1593 400 1200

342 151 1000

1200 2517

3020 1180

1416 885

1062 400 800

353

379

398

399 151 1000

1200 2517

3020 1180

1416 885

1062 400 800

183 1000

1200 3050

3660 1180

1416 885

1062 400 800

3500 151 1000

1200

1500

1800 2517

3020

3775

4530 1180

1416

1770

2124 885

1062

1328

1593 400 800

183 1000

1200 3050

3660 1180

1416 885

1062&nbs