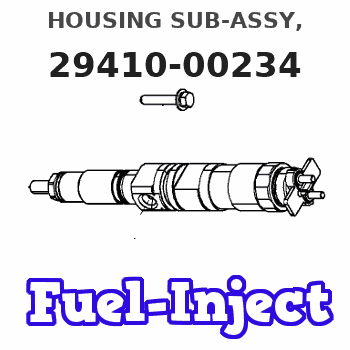

Information housing sub-assy,

Rating:

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29410-00234 | HOUSING SUB-ASSY, |

Information:

Landfill Compactor: 816F Series 2 (S/N: BZR1-UP)Soil Compactor: 815F Series 2 (S/N: BYN1-UP)Engine: C7 (S/N: RMF1-UP; FML1-UP; FMM1-UP; WAX1-UP; PRY1-UP) C9 (S/N: LFE1-UP; 9DG1-UP; CKP1-UP)Truck Engines: C7 TRUCK ENGINE (S/N: LBM1-UP)Excavator: 324D (S/N: LAB1-UP; EJC1-UP; MND1-UP; T2D1-UP; BYE1-UP; JJG1-UP; ECH1-UP; TRH1-UP; BTK1-UP; SYM1-UP; AWN1-UP; TSN1-UP; DFP1-UP; JKR1-UP; JZR1-UP; JLS1-UP; JAT1-UP; PYT1-UP; CJX1-UP) 325D (S/N: GPB1-UP; NAC1-UP; KBE1-UP; PKE1-UP; KDG1-UP; C4H1-UP; DBH1-UP; C7K1-UP; ERK1-UP; RJK1-UP; C8L1-UP; LAL1-UP; MCL1-UP; C9M1-UP; DAP1-UP; A3R1-UP; GBR1-UP; SCR1-UP) 328D (S/N: BYH1-UP; GTN1-UP; MKR1-UP) 329D (S/N: MNB1-UP; XDB1-UP; BFC1-UP; BBF1-UP; CZF1-UP; DJF1-UP; L5H1-UP; JHJ1-UP; RSK1-UP; WDK1-UP; EBM1-UP; TPM1-UP; BYS1-UP; WLT1-UP; LFW1-UP; YFW1-UP; SCY1-UP; TAY1-UP; DTZ1-UP) 330D (S/N: PFC1-UP; NBD1-UP; R2D1-UP; GGE1-UP; NEF1-UP; B6H1-UP; EAH1-UP; LCJ1-UP; THJ1-UP; C5K1-UP; E4K1-UP; FFK1-UP; H3K1-UP; L2K1-UP; RDK1-UP; PEL1-UP; JJM1-UP; LEM1-UP; LRM1-UP; ERN1-UP; JLP1-UP; MWP1-UP; RAS1-UP; MEY1-UP) 336D (S/N: SKE1-UP; JBF1-UP; J2F1-UP; PRF1-UP; LMG1-UP; MYG1-UP; KDJ1-UP; WRK1-UP; W3K1-UP; MPL1-UP; PPN1-UP; MYP1-UP; M2P1-UP; JER1-UP; DTS1-UP; NLS1-UP; JBT1-UP; KKT1-UP; M4T1-UP; WET1-UP; PGW1-UP; L5X1-UP)Forwarder: 584 (S/N: PAK1-UP) 584HD (S/N: PBK1-UP)Track Feller Buncher: 2390 (S/N: P3H1-UP) 2491 (S/N: P5J1-UP) 511 (S/N: 5111-UP) 521 (S/N: 5211-UP) 522 (S/N: 5221-UP) 532 (S/N: 5321-UP) 552 (S/N: 5521-UP)Motor Grader: 120K (S/N: SZN1-UP; JAP1-UP) 12K (S/N: JJA1-UP; SZP1-UP) 140K (S/N: JPA1-UP; SZL1-UP) 140M (S/N: B9D1-UP; B9G1-UP; D9G1-UP) 160K (S/N: SZM1-UP; JBP1-UP) 160M Series II (S/N: M9E1-UP) 160M (S/N: B9E1-UP; B9L1-UP; B9T1-UP; D9T1-UP)Mobile Hydraulic Power Unit: 323D MHPU (S/N: DCY1-UP) 324D MHPU (S/N: KJR1-UP) 325D MHPU (S/N: SRC1-UP; C3N1-UP; H3N1-UP; X3N1-UP) 328D MHPU (S/N: JTC1-UP) 329D MHPU (S/N: J9D1-UP) 330D MHPU (S/N: D3D1-UP; H3D1-UP; M3D1-UP; GMN1-UP) 336D MHPU (S/N: J6D1-UP; M3N1-UP)Track-Type Loader: 973C (S/N: LDX1-UP)Track-Type Tractor: D6R Series III (S/N: EXW1-UP) D6T (S/N: SNK1-UP)Wheel Dozer: 814F Series 2 (S/N: BXG1-UP)Wheel Loader: 950H (S/N: N1A1-UP; M1G1-UP; J5J1-UP; K5K1-UP) 962H (S/N: N4A1-UP; M3G1-UP; J6J1-UP; K6K1-UP; MAL1-UP)Wheel Skidder: 525C (S/N: 5251-UP) 535C (S/N: 5351-UP) 545C (S/N: 5451-UP)Wheel Tractor-Scraper: 627G (S/N: DBD1-UP; DBZ1-UP) 637G (S/N: DEX1-UP)Introduction

The problem that is identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is listed below.Problem

A significant amount of HEUI pumps and injectors have been returned, but no cause of failure can be determined.Solution

Diagnostic procedures have been updated and have been incorporated into the following publications:

Special Instruction, REHS3819, "Procedure for Troubleshooting and Cleaning the Oil Rail System for the Hydraulic Electronic Unit Injector (HEUI)"

Troubleshooting, "Injection Actuation Pressure - Test"Note: These publications have been translated into Mandarin and Spanish.In addition, a new troubleshooting checklist is included with all service repair for HUEI pumps and HEUI injectors. The checklist is a summary of the diagnostic procedure steps to be confirmed before a suspect component is replaced. The checklist must be completed and returned with the suspect components in order to aid engineering to determine the cause of failure.Following the instructions step-by-step is critical in order to diagnose the failed component correctly. Do not skip steps in the procedures. Skipping steps in the procedure will lead to incorrect diagnosis of the problem.

The problem that is identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is listed below.Problem

A significant amount of HEUI pumps and injectors have been returned, but no cause of failure can be determined.Solution

Diagnostic procedures have been updated and have been incorporated into the following publications:

Special Instruction, REHS3819, "Procedure for Troubleshooting and Cleaning the Oil Rail System for the Hydraulic Electronic Unit Injector (HEUI)"

Troubleshooting, "Injection Actuation Pressure - Test"Note: These publications have been translated into Mandarin and Spanish.In addition, a new troubleshooting checklist is included with all service repair for HUEI pumps and HEUI injectors. The checklist is a summary of the diagnostic procedure steps to be confirmed before a suspect component is replaced. The checklist must be completed and returned with the suspect components in order to aid engineering to determine the cause of failure.Following the instructions step-by-step is critical in order to diagnose the failed component correctly. Do not skip steps in the procedures. Skipping steps in the procedure will lead to incorrect diagnosis of the problem.