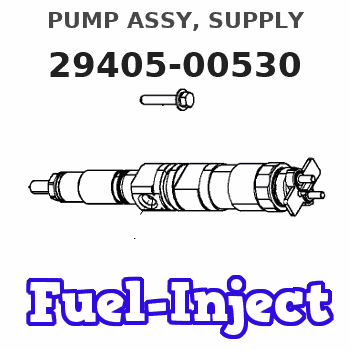

Information pump assy, supply

PUMP ASSY, SUPPLY

DA

- THIS CAN BE USED IN PLACE OF 294050-001# AS A SUPPLY.

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump CR HP4 294050-0530 22100-0273-A Compatible For Hino J08E J09C 7.7L Engine

SDETASOQ Precise control: precise fuel injection, optimized combustion efficiency, reduced fuel consumption, and improved engine power output || Long lifespan and low maintenance: using high-strength wear-resistant alloy materials and corrosion-resistant coatings to reduce maintenance costs and downtime || Stable operation under all operating conditions: tested in extreme environments, continuously stable, and adaptable to various complex road and climate conditions || Silent and efficient operation: Adopting a noise reduction structure, it can maintain quietness even during high-speed operation, without interfering with the driving experience || Fuel Injection Pump CR HP4 294050-0530 22100-0273-A Compatible For Hino J08E J09C 7.7L Engine

SDETASOQ Precise control: precise fuel injection, optimized combustion efficiency, reduced fuel consumption, and improved engine power output || Long lifespan and low maintenance: using high-strength wear-resistant alloy materials and corrosion-resistant coatings to reduce maintenance costs and downtime || Stable operation under all operating conditions: tested in extreme environments, continuously stable, and adaptable to various complex road and climate conditions || Silent and efficient operation: Adopting a noise reduction structure, it can maintain quietness even during high-speed operation, without interfering with the driving experience || Fuel Injection Pump CR HP4 294050-0530 22100-0273-A Compatible For Hino J08E J09C 7.7L Engine

294050-0530 22100-E0273 22100-E0273-A HP4 Fuel Injection Pump Suitable for Hino J08E J09C 7.7L ND NE NJ NV Engine 500 Series Trucks

OfkZynodor Part Name:Fuel Injection Pump || Part Number:294050-0530 22100-E0273 22100-E0273-A || Application:Suitable for Hino J08E J09C 7.7L ND NE NJ NV Engine 500 Series Trucks || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

OfkZynodor Part Name:Fuel Injection Pump || Part Number:294050-0530 22100-E0273 22100-E0273-A || Application:Suitable for Hino J08E J09C 7.7L ND NE NJ NV Engine 500 Series Trucks || Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

For Hino 500 series Truck Fuel Injection Pump 294050-0530 22100-E0273 For Hino J08E J09C Engine

KoovDem Part Number: 294050-0530 22100-E0273 2940500530 22100E0273 || Part Name: 294050-0530 22100-E0273 Fuel Injection Pump || Suitable for use with Hino J08E J09C Engine. || Designed for Hino's 500 series trucks, this product is built to seamlessly integrate with the vehicle for smooth operation. With high-quality construction and engineering tailored for Hino 500 series, it guarantees optimal performance for maintenance, repairs, or upgrades. Trustworthy and dependable, it meets rigorous Hino standards, ensuring your truck runs efficiently and effectively. || Please carefully review the product image and part number to ensure that it is the correct item before making a purchase. This will help prevent any unnecessary returns or exchanges.

KoovDem Part Number: 294050-0530 22100-E0273 2940500530 22100E0273 || Part Name: 294050-0530 22100-E0273 Fuel Injection Pump || Suitable for use with Hino J08E J09C Engine. || Designed for Hino's 500 series trucks, this product is built to seamlessly integrate with the vehicle for smooth operation. With high-quality construction and engineering tailored for Hino 500 series, it guarantees optimal performance for maintenance, repairs, or upgrades. Trustworthy and dependable, it meets rigorous Hino standards, ensuring your truck runs efficiently and effectively. || Please carefully review the product image and part number to ensure that it is the correct item before making a purchase. This will help prevent any unnecessary returns or exchanges.

You can express buy:

USD 402.48

01-06-2025

01-06-2025

Diesel Injector Pump Fuel Injection Pump 294050-0360 294050-0530 22100-E0351 22100-E0273-A For HINO J08E

USD 406.83

14-06-2025

14-06-2025

Diesel Injector Pump Fuel Injection Pump 294050-0360 294050-0530 22100-E0351 22100-E0273-A For HINO J08E

Images:

USD 771.12

[05-May-2025]

USD 384.72

[14-Jun-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29405-00530 |

| 002. | OVERHAUL KIT, SUPP | 29400-90051 |

Scheme ###:

| 000. | [01] | 29405-00530 | PUMP ASSY, SUPPLY | 22100-E0273-A |

| 001. | [01] | 29410-05720 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15040 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10040 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90110 | BOLT, SOCKET | |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35020 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45040 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [05] | 09644-90050 | BOLT, SOCKET | S2273-31010-A |

| 015. | [02] | 29409-00660 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00670 | ELEMENT KIT, SUPPL | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00020 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-03680 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50010 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00200 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05000 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 041. | [01] | 94918-00060 | SCREW, HOLLOW | S2283-51110-A |

| 042. | [02] | 94901-02470 | WASHER | S2284-71900-A |

| 043. | [01] | 94919-80260 | COLLAR, PRESSBOARD | S2233-21650-A |

| 044. | [01] | 94918-00310 | SCREW, HOLLOW | S2283-51310-A |

| 045. | [02] | 94901-02490 | WASHER | S2287-71100-A |

| 046. | [01] | 94919-80270 | COLLAR, PRESSBOARD | S2284-32240-A |

| 047. | [02] | 09031-70060 | PLUG, SCREW | S2284-51060-A |

| 048. | [02] | 09806-50020 | GASKET | |

| 049. | [01] | 94905-62390 | NUT | S2282-52570-A |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90020 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90051 | OVERHAUL KIT, SUPP |

Include in #3:

29405-00530

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00530 | 22100-E027 | PUMP ASSY, SUPPLY | |

| 22100-E0273-A | HINO | PUMP ASSY, SUPPLY |

Information:

Governors and Actuators

Your engine may be equipped with a:* full-range governor* Woodward PSG Governor* Woodward 1724 Actuator* Woodward 524 Actuator

PSG Actuator

1724/524 ActuatorWoodward Governors/Actuators are usually electrically operated from a control panel. The application is usually an EPG power generator set. On standby gen sets the governor may be set to operate only at Full Load Speed.Change Engine Speed

If equipped with a control panel, a RAISE/LOWER switch or a speed setting potentiometer is used to adjust the operating speed.Starting, Operating and Stopping Engines Equipped with Control Panels

For all information regarding the generator control panel used for starting, operating and stopping the engine, refer to the Engine Protection Devices Generator Set Control Panel topic in this publication or Caterpillar SR4 Generators and Control Panels, SEBU6150. Additional information and programming instructions are provided in the Service Manual for your specific control panel.Mechanical Governors (If Equipped)

Governor Control LeverYour engine may be equipped with a full-range governor. Most other manufacturers' engines have min-max type governors that only govern at high and low idle to prevent the engine from overspeeding or dying. With the min-max governor, the position of the speed lever determines the amount of fuel delivered to the engine.With the full-range governor, the position of the speed lever sets engine speed and helps hold a constant speed independent of load which makes operation easier.The governor control motor is a 24 volt motor which allows for engine speed control from a remote location through a governor RAISE/LOWER switch. This governor control switch is used with the optional EMCP II. Always increase engine speed to high idle before applying load.For information regarding initial checks and adjustments, refer to the Service Manual or contact your Caterpillar dealer.Driven Equipment Without Load

1. Move the governor control lever to half engine speed.2. Interrupted starts put excessive stress on the drive train and waste fuel. To get the driven equipment in motion, engage the clutch smoothly, with no load on the equipment. This should result in a smooth, easy start without increasing the engine speed above low idle or slipping the clutch. For generator sets, move the governor control to high idle (full load) position (1800 rpm for 60 Hz and 1500 rpm for 50 Hz).3. Apply the load and check the gauges and equipment for proper operation. Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load. Do not allow the engine speed (rpm) to exceed the limit above rated rpm. DO NOT allow the engine to overspeed.If the load varies, or is cyclic, the governor will adjust the engine speed as required.The governor control lever should remain in the full governed position while operating at full load.Extended operation at low idle or reduced load may cause increased oil consumption and carbon build-up in the cylinders. This carbon build-up results in loss of power and/or poor performance. When operating at reduced load, the engine should be fully loaded to burn

Your engine may be equipped with a:* full-range governor* Woodward PSG Governor* Woodward 1724 Actuator* Woodward 524 Actuator

PSG Actuator

1724/524 ActuatorWoodward Governors/Actuators are usually electrically operated from a control panel. The application is usually an EPG power generator set. On standby gen sets the governor may be set to operate only at Full Load Speed.Change Engine Speed

If equipped with a control panel, a RAISE/LOWER switch or a speed setting potentiometer is used to adjust the operating speed.Starting, Operating and Stopping Engines Equipped with Control Panels

For all information regarding the generator control panel used for starting, operating and stopping the engine, refer to the Engine Protection Devices Generator Set Control Panel topic in this publication or Caterpillar SR4 Generators and Control Panels, SEBU6150. Additional information and programming instructions are provided in the Service Manual for your specific control panel.Mechanical Governors (If Equipped)

Governor Control LeverYour engine may be equipped with a full-range governor. Most other manufacturers' engines have min-max type governors that only govern at high and low idle to prevent the engine from overspeeding or dying. With the min-max governor, the position of the speed lever determines the amount of fuel delivered to the engine.With the full-range governor, the position of the speed lever sets engine speed and helps hold a constant speed independent of load which makes operation easier.The governor control motor is a 24 volt motor which allows for engine speed control from a remote location through a governor RAISE/LOWER switch. This governor control switch is used with the optional EMCP II. Always increase engine speed to high idle before applying load.For information regarding initial checks and adjustments, refer to the Service Manual or contact your Caterpillar dealer.Driven Equipment Without Load

1. Move the governor control lever to half engine speed.2. Interrupted starts put excessive stress on the drive train and waste fuel. To get the driven equipment in motion, engage the clutch smoothly, with no load on the equipment. This should result in a smooth, easy start without increasing the engine speed above low idle or slipping the clutch. For generator sets, move the governor control to high idle (full load) position (1800 rpm for 60 Hz and 1500 rpm for 50 Hz).3. Apply the load and check the gauges and equipment for proper operation. Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load. Do not allow the engine speed (rpm) to exceed the limit above rated rpm. DO NOT allow the engine to overspeed.If the load varies, or is cyclic, the governor will adjust the engine speed as required.The governor control lever should remain in the full governed position while operating at full load.Extended operation at low idle or reduced load may cause increased oil consumption and carbon build-up in the cylinders. This carbon build-up results in loss of power and/or poor performance. When operating at reduced load, the engine should be fully loaded to burn