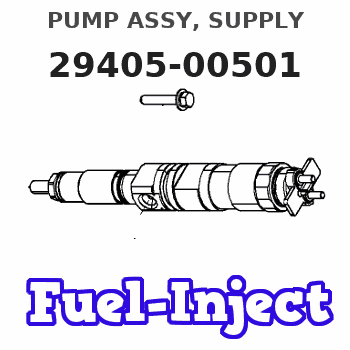

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Injection Fuel Pump Assy 294050-0500 294050-0501 33100-52701 3310052701

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

Diesel Injection Fuel Pump Assy 294050-0500 294050-0501 33100-52701 3310052701

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

Diesel Injection Fuel Pump Assy 294050-0500 294050-0501 33100-52701 3310052701

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

You can express buy:

USD 410

14-06-2025

14-06-2025

New Diesel Injection Fuel Pump Assy 294050-0500 294050-0501 33100-52701 3310052701

Images:

USD 688.75

[19-May-2025]

USD 424.27

[19-May-2025]

USD 382.67

[13-May-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00501 | 3310052701 | PUMP ASSY, SUPPLY |

Information:

S O S Sampling Valve (if equipped) Obtain at Every 250 Hour Interval or Oil Change.Obtain S O S samples at regularly scheduled intervals to monitor the condition and maintenance requirements of your engine. Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the engine crankcase.Consult your Caterpillar dealer for complete information and assistance in establishing an S O S program for your engine(s).S O S Analysis

S O S is composed of three basic tests: * Wear Analysis* Chemical and Physical Tests* Oil Condition Analysis Wear analysis is performed with an atomic absorption spectrophotometer to monitor component wear by identifying and measuring concentrations, in parts per million, of wear elements present in the oil. Based on known normal concentration data, maximum limits of wear elements are established. Impending failures can be identified when test results deviate from concentration levels established as acceptable, based on normal wear. Chemical and physical tests detect the presence of water, fuel and glycol (antifreeze) in the oil and determine whether or not their concentrations exceed established maximum limits. Oil condition is evaluated with infrared analysis. This test determines the presence and measures the amount of contaminants such as soot, sulfur products, oxidation, and nitration products in the oil. Infrared analysis can also assist in customizing (reducing, maintaining or extending) oil change intervals for particular conditions and applications.Infrared analysis should always be accompanied by wear element analysis and chemical and physical tests to assure accurate diagnosis. Infrared analysis must be used to determine oil change intervals. S O S must include Infrared (IR) in the analysis.The test results of the oil samples will then be used as a basis for determining the oil change interval for your engine, giving you the ultimate time between oil changes without the risk of engine damage.Refer to Caterpillar pamphlet Scheduled Oil Sampling, form PEDP7105 for information and benefits of S O S.