Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

ME307484 ME306611 CR HP4 Fuel Injection Pump for Mitsubishi Fuso 6M60 6M60T Engine 294050-0460 294050-0461

KoovDem Part Number: 294050-0460 294050-0461 ME307484 ME306611 || Engine Model: for Mitsubishi Engine 6M60 6M60T || The HP4 Diesel Common Rail Fuel Pump is a high-performing and efficient fuel pump designed for diesel engines. With advanced common rail technology, it provides precise and consistent fuel delivery to enhance engine performance and fuel efficiency. Made with high-quality materials for durability, it is suitable for a variety of diesel engines and can handle high-pressure fuel systems. This reliable and essential component ensures the proper functioning of diesel engines. || for verification. This will help ensure that you receive the correct part for your vehicle. It is important to double check the accuracy of the part numbers to avoid any delays or inconvenience. Thank you for your attention to detail and for choosing our services. || Service: Enjoy peace of mind with our 6-month warranty and round-the-clock support for all your customer service needs. For any inquiries or concerns about our product, don't hesitate to reach out to us via email.

KoovDem Part Number: 294050-0460 294050-0461 ME307484 ME306611 || Engine Model: for Mitsubishi Engine 6M60 6M60T || The HP4 Diesel Common Rail Fuel Pump is a high-performing and efficient fuel pump designed for diesel engines. With advanced common rail technology, it provides precise and consistent fuel delivery to enhance engine performance and fuel efficiency. Made with high-quality materials for durability, it is suitable for a variety of diesel engines and can handle high-pressure fuel systems. This reliable and essential component ensures the proper functioning of diesel engines. || for verification. This will help ensure that you receive the correct part for your vehicle. It is important to double check the accuracy of the part numbers to avoid any delays or inconvenience. Thank you for your attention to detail and for choosing our services. || Service: Enjoy peace of mind with our 6-month warranty and round-the-clock support for all your customer service needs. For any inquiries or concerns about our product, don't hesitate to reach out to us via email.

Compatible with Mitsubishi Engine 6M60 6M60T Fuel Injection Pump 294050-0461 ME306611 294050-0460

KoovDem Part Number: 294050-0461 ME306611 294050-0460 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with the Mitsubishi Engine 6M60 and 6M60T, this product is fully compatible and ready for installation. Designed to seamlessly integrate with the engine system, this component ensures optimal performance and efficiency. Whether for maintenance, repair, or upgrades, this product is the perfect fit for your Mitsubishi Engine 6M60 and 6M60T. || 1 piece of Fuel Injection Pump is included in the package, with model numbers 294050-0461, ME306611, and 294050-0460.

KoovDem Part Number: 294050-0461 ME306611 294050-0460 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with the Mitsubishi Engine 6M60 and 6M60T, this product is fully compatible and ready for installation. Designed to seamlessly integrate with the engine system, this component ensures optimal performance and efficiency. Whether for maintenance, repair, or upgrades, this product is the perfect fit for your Mitsubishi Engine 6M60 and 6M60T. || 1 piece of Fuel Injection Pump is included in the package, with model numbers 294050-0461, ME306611, and 294050-0460.

306611 294050-0461 ME307484 HP4 Diesel Common Rail Fuel Pump ME Suitable for Mitsubishi 6M60T 6M60 Engine

OfkZynodor Part Name:Fuel Pump || Part Number:ME306611 294050-0461 ME307484 || Application:Suitable for Mitsubishi 6M60T 6M60 Engine || Attention:Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || NOTE:Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

OfkZynodor Part Name:Fuel Pump || Part Number:ME306611 294050-0461 ME307484 || Application:Suitable for Mitsubishi 6M60T 6M60 Engine || Attention:Please make sure to carefully compare the photos and check the part numbers before making the purchase. If you are unable to confirm your engine model or part number, please leave us a message and we will assist you in confirming that the product you purchase is the one you need. || NOTE:Your order is not merely a single purchase but the beginning of a cooperative journey, aiming to ensure the safe and smooth operation of your vehicle. We are proud to offer you reliable precision engineering components and unparalleled services.

You can express buy:

USD 525

13-05-2025

13-05-2025

Fuel Pump For Mitsubishi Fuso Fighter 6M60T 6M60 High Pressure Common Rail Oil Pump 294050-0460 294050-0461 ME307484 ME306611

USD 400.98

13-05-2025

13-05-2025

HP4 Diesel Injector Pump Fuel Injection Pump 294050-0460 294050-0461 ME307484 ME306611 for MITSUBISHI 6M60T

Images:

USD 651.84

[19-May-2025]

USD 499.13

[30-Apr-2025]

USD 461.01

[26-May-2025]

USD 51.9

[27-Apr-2025]

Components :

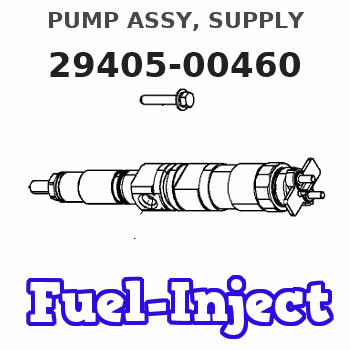

| 001. | PUMP ASSY, SUPPLY | 29405-00460 |

| 001. | PUMP ASSY, SUPPLY | 29405-00460 |

| 002. | OVERHAUL KIT, SUPP | 29400-90050 |

Scheme ###:

| 000. | [01] | 29405-00460 | PUMP ASSY, SUPPLY | ME306611 |

| 000. | [01] | 29405-00461 | PUMP ASSY, SUPPLY | ME307484 |

| 001. | [01] | 29410-05052 | HOUSING SUB-ASSY, | |

| 001. | [01] | 29410-05571 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15010 | CAMSHAFT, SUPPLY P | |

| 003. | [01] | 29419-15090 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10040 | KEY, WOODRUFF | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05070 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [08] | 09644-90110 | BOLT, SOCKET | ME736324 |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35030 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45010 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [03] | 09644-90050 | BOLT, SOCKET | |

| 015. | [01] | 29409-00620 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00710 | ELEMENT KIT, SUPPL | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 021. | [01] | 29409-00630 | ELEMENT KIT, SUPPL | |

| 022. | [03] | 29419-80020 | O-RING, SUPPLY PUM | |

| 023. | [03] | 29413-50012 | PLUG, CYLINDER | |

| 024. | [03] | 29414-00150 | VALVE SUB-ASSY, SU | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00670 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50010 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00200 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05050 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 041. | [01] | 09543-80170 | SCREW, HOLLOW | ME743860 |

| 042. | [02] | 94901-02530 | WASHER | ME743814 |

| 044. | [01] | 94918-00310 | SCREW, HOLLOW | ME702236 |

| 045. | [02] | 94901-02490 | WASHER | ME743859 |

| 047. | [01] | 09031-70060 | PLUG, SCREW | ME702176 |

| 048. | [01] | 09806-50020 | GASKET | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 053. | [01] | 94919-80260 | COLLAR, PRESSBOARD | ME702848 |

| 054. | [01] | 94919-80270 | COLLAR, PRESSBOARD | ME702632 |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90050 | OVERHAUL KIT, SUPP | |

| 201. | [03] | 29400-90940 | OVERHAUL KIT, SUPP | |

| 300. | [01] | 29409-05050 | ELEMENT KIT, SUPPL | |

| 301. | [02] | 29409-05060 | ELEMENT KIT, SUPPL |

Include in #3:

29405-00460

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00460 | ME306611 | PUMP ASSY, SUPPLY | |

| ME306611 | MITSUBISHI | PUMP ASSY, SUPPLY | |

| ME307484 | MITSUBISHI | PUMP ASSY, SUPPLY |

Information:

Safety

The safety section lists basic safety precautions. In addition, this section identifies the text and locations of warning labels used on the engine.Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and repair on this product.Operation

Illustrations guide the operator through correct procedures of checking, starting, operating and stopping the engine.The operation section is a reference for the new operator and a refresher for the experienced one.The operating sections outlined in this publication are organized to assist you with developing the skills and techniques required to operate your engine more efficiently and economically.Maintenance

The maintenance section is a guide to equipment care. The illustrated, step-by-step instructions are grouped by Preventive Maintenance servicing intervals. Items in the "Maintenance Management Schedule" are referenced to detailed instructions that follow.The "Maintenance Management Schedule" items are organized for a Preventive Maintenance Program.If the Preventive Maintenance Program is followed, a periodic tune-up is not required. The implementation of a Preventive Maintenance Management Program should minimize operating costs through cost avoidances resulting from reductions in unscheduled downtime and failures.Maintenance Intervals

The service interval for each item listed in the "Maintenance Management Schedule" is primarily based on the item and its relationship to either engine speed or load.We recommend that these schedules be reproduced for ease of inspection. We also recommend that a maintenance record be maintained as part of the equipment's permanent record.See the "Maintenance Log" section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair.Your authorized Caterpillar dealer can assist you in tailoring your schedule to meet the needs of your operating environment.

The safety section lists basic safety precautions. In addition, this section identifies the text and locations of warning labels used on the engine.Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and repair on this product.Operation

Illustrations guide the operator through correct procedures of checking, starting, operating and stopping the engine.The operation section is a reference for the new operator and a refresher for the experienced one.The operating sections outlined in this publication are organized to assist you with developing the skills and techniques required to operate your engine more efficiently and economically.Maintenance

The maintenance section is a guide to equipment care. The illustrated, step-by-step instructions are grouped by Preventive Maintenance servicing intervals. Items in the "Maintenance Management Schedule" are referenced to detailed instructions that follow.The "Maintenance Management Schedule" items are organized for a Preventive Maintenance Program.If the Preventive Maintenance Program is followed, a periodic tune-up is not required. The implementation of a Preventive Maintenance Management Program should minimize operating costs through cost avoidances resulting from reductions in unscheduled downtime and failures.Maintenance Intervals

The service interval for each item listed in the "Maintenance Management Schedule" is primarily based on the item and its relationship to either engine speed or load.We recommend that these schedules be reproduced for ease of inspection. We also recommend that a maintenance record be maintained as part of the equipment's permanent record.See the "Maintenance Log" section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair.Your authorized Caterpillar dealer can assist you in tailoring your schedule to meet the needs of your operating environment.