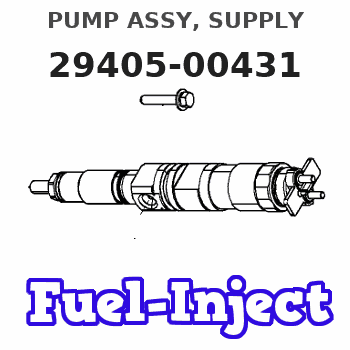

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

HP4 Diesel Injector Pump Fuel Injection Pump 294050-0430 294050-0431 ME306444 ME307486 Compatible For MITSUBISHI 6M60T

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

IUFDCVRJ Convenient installation: it fits the structure of the vehicle, is simple and convenient to install, and can be upgraded and used directly without complicated modification. || Durable material: high-strength material, with excellent wear resistance and corrosion resistance, can withstand high pressure and complex working environment. || Silent operation: optimize the internal structure and working principle, and the noise is extremely low during operation, creating a quiet and comfortable driving experience for you. || Precise fuel control: the fuel injection quantity is accurately controlled, and the injected fuel quantity is accurately adapted to different road conditions to maximize fuel utilization. || Improve power: optimize fuel injection time and pressure, so that the engine's working efficiency is greatly improved, the acceleration is faster and the torque is stronger.

HP4 Diesel Injector Pump Fuel Injection Pump 294050-0430 294050-0431 ME306444 ME307486 Compatible For MITSUBISHI 6M60T

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

HP4 Diesel Injector Pump Fuel Injection Pump 294050-0430 294050-0431 ME306444 ME307486 Compatible For MITSUBISHI 6M60T

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

You can express buy:

USD 421.8

14-06-2025

14-06-2025

HP4 Diesel Fuel Injection pump 294050-0430 ME306444 294050-0431 ME307486 IN STOCK For MITSUBISHI 6M60T engine

Images:

USD 569.05

[13-May-2025]

USD 512.05

[13-May-2025]

USD 438.52

[19-May-2025]

USD 389.2

[08-May-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00431 | ME307486 | PUMP ASSY, SUPPLY |

Information:

Auxiliary engine braking devices are approved for use on the 3406B PEEC Engine.Compression Brake

Operation (Jacobs Brake or Pacific Brake)

The Jacobs Engine Brake should not be used as a primary or service brake. Do not allow the engine to exceed 2300 rpm. However, engines equipped with a Jacobs Engine Brake should not normally be operated above 2100 rpm.

The Jacobs Engine Brake is an engine attachment that converts a diesel engine into an air compressor. Its function is to slow the vehicle and reduce brake wear.Operating Controls-Compression Brake

The Jacobs Engine Brake controls may include a dash mounted module or an ON/OFF switch and a three position switch with "Lo" and "Hi" depending on how many cylinders of braking desired. Refer to the OEM vehicle manual for the type of operating controls that your vehicle is equipped with.The PEEC ECM monitors the clutch, brake, throttle position and engine rpm to determine when the Jacobs Brake can operate. It may take up to two seconds before Jacobs Brake activates.Since the Jacobs Engine Brake is most effective at rated engine rpm, gear selection is very important. Gearing down the vehicle, within the limits of rated engine rpm, makes the engine brake a more effective retarder. Maximum retarding occurs at higher engine rpm.Cruise Control (If Equipped) OFF

With the Cruis Control (CC) in the OFF position the Jacobs Engine Brake will function like any vehicle and engine that is not equipped with Cruise Control (CC).Cruise Control (If Equipped) ON

The driver must apply the service brake approximately two seconds and then release the service brake pedal. If the retarder "Latch" mode has been programmed, the retarder will continue to slow the vehicle. To release or deactivate the retarder, the clutch or throttle foot pedal must be depressed or the engine rpm drop to 950 rpm.When using "Coast" mode, the Jacobs Brake should activate within two seconds after the brake pedal is applied and remain on as long as the brake pedal is applied. At the time the brake pedal is applied, the Cruise Control (CC) will deactivate.For information on adjustment to Jacobs Brake slave piston lash, refer to PM Level 2-Engine Valve Lash. Refer to Jacobs Brake Troubleshooting Manual, Form SENR4251 for information regarding this auxiliary braking system.There are differences in exhaust braking devices from those with little or no leakage when activated to those with a great deal of leakage.Sliding Gate Type (Williams Blue Ox)

This type of exhaust brake allows minimal leakage and must have a relief orifice to limit the maximum exhaust manifold back pressure to 50 psi (345 kPa) at maximum engine braking rpm. Flapper Type (Pacific)

With this type of exhaust brake, there is usually leakage around the movable plate. To obtain 50 psi (345 kPa) or 70 psi (485 kPa) performance level braking, a small hole would likely be required. The maximum permissible exhaust back pressure at maximum engine braking rpm is measured at the 1/4 NPT hole in the exhaust manifold below the turbocharger.Refer to the April, 1988 "Truck Engine Application

Operation (Jacobs Brake or Pacific Brake)

The Jacobs Engine Brake should not be used as a primary or service brake. Do not allow the engine to exceed 2300 rpm. However, engines equipped with a Jacobs Engine Brake should not normally be operated above 2100 rpm.

The Jacobs Engine Brake is an engine attachment that converts a diesel engine into an air compressor. Its function is to slow the vehicle and reduce brake wear.Operating Controls-Compression Brake

The Jacobs Engine Brake controls may include a dash mounted module or an ON/OFF switch and a three position switch with "Lo" and "Hi" depending on how many cylinders of braking desired. Refer to the OEM vehicle manual for the type of operating controls that your vehicle is equipped with.The PEEC ECM monitors the clutch, brake, throttle position and engine rpm to determine when the Jacobs Brake can operate. It may take up to two seconds before Jacobs Brake activates.Since the Jacobs Engine Brake is most effective at rated engine rpm, gear selection is very important. Gearing down the vehicle, within the limits of rated engine rpm, makes the engine brake a more effective retarder. Maximum retarding occurs at higher engine rpm.Cruise Control (If Equipped) OFF

With the Cruis Control (CC) in the OFF position the Jacobs Engine Brake will function like any vehicle and engine that is not equipped with Cruise Control (CC).Cruise Control (If Equipped) ON

The driver must apply the service brake approximately two seconds and then release the service brake pedal. If the retarder "Latch" mode has been programmed, the retarder will continue to slow the vehicle. To release or deactivate the retarder, the clutch or throttle foot pedal must be depressed or the engine rpm drop to 950 rpm.When using "Coast" mode, the Jacobs Brake should activate within two seconds after the brake pedal is applied and remain on as long as the brake pedal is applied. At the time the brake pedal is applied, the Cruise Control (CC) will deactivate.For information on adjustment to Jacobs Brake slave piston lash, refer to PM Level 2-Engine Valve Lash. Refer to Jacobs Brake Troubleshooting Manual, Form SENR4251 for information regarding this auxiliary braking system.There are differences in exhaust braking devices from those with little or no leakage when activated to those with a great deal of leakage.Sliding Gate Type (Williams Blue Ox)

This type of exhaust brake allows minimal leakage and must have a relief orifice to limit the maximum exhaust manifold back pressure to 50 psi (345 kPa) at maximum engine braking rpm. Flapper Type (Pacific)

With this type of exhaust brake, there is usually leakage around the movable plate. To obtain 50 psi (345 kPa) or 70 psi (485 kPa) performance level braking, a small hole would likely be required. The maximum permissible exhaust back pressure at maximum engine braking rpm is measured at the 1/4 NPT hole in the exhaust manifold below the turbocharger.Refer to the April, 1988 "Truck Engine Application