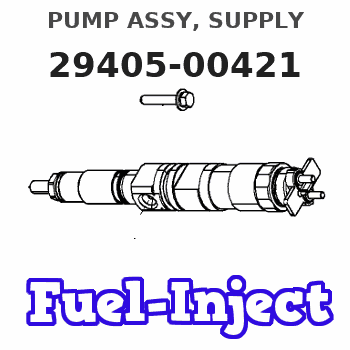

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

8-97605946-8 CR HP4 Fuel Injection Pump Compatible with Isuzu 6HK1 6HK1-TCC 6HK1-TCN 7.8L Engine F-Series FRR FSR FTR FVR FSS FVZ Trucks 294050-0422 294050-0423 294050-0424

KoovDem Part Number: 294050-0420 294050-0421 294050-0422 294050-0423 294050-0424 8-97605946-0 8-97605946-1 8-97605946-2 8-97605946-3 8-97605946-4 8-97605946-5 8-97605946-7 8-97605946-8 || Vehicle Application:For Isuzu F-Series FRR FSR FTR FVR FSS FVZ Trucks || Specifically designed for Isuzu 6HK1, the powerful 7.8L engine comes in 6HK1-TCC and 6HK1-TCN variants. Known for reliability and efficiency, it is a top choice for heavy-duty use in commercial fleets, construction equipment, and industrial machinery. Engineered for durability and performance, the Isuzu 6HK1 engine offers impressive power output in a compact, robust package, making it a trusted option for demanding applications. || We are committed to assisting you in finding the perfect pump for your vehicle to ensure optimal performance and prevent potential issues. Regular maintenance and inspections can help prolong the pump's lifespan and prevent breakdowns. Follow manufacturer guidelines for installation and usage. Contact us for any questions or assistance. Thank you for choosing our products. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

KoovDem Part Number: 294050-0420 294050-0421 294050-0422 294050-0423 294050-0424 8-97605946-0 8-97605946-1 8-97605946-2 8-97605946-3 8-97605946-4 8-97605946-5 8-97605946-7 8-97605946-8 || Vehicle Application:For Isuzu F-Series FRR FSR FTR FVR FSS FVZ Trucks || Specifically designed for Isuzu 6HK1, the powerful 7.8L engine comes in 6HK1-TCC and 6HK1-TCN variants. Known for reliability and efficiency, it is a top choice for heavy-duty use in commercial fleets, construction equipment, and industrial machinery. Engineered for durability and performance, the Isuzu 6HK1 engine offers impressive power output in a compact, robust package, making it a trusted option for demanding applications. || We are committed to assisting you in finding the perfect pump for your vehicle to ensure optimal performance and prevent potential issues. Regular maintenance and inspections can help prolong the pump's lifespan and prevent breakdowns. Follow manufacturer guidelines for installation and usage. Contact us for any questions or assistance. Thank you for choosing our products. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

294050-0420 294050-0421 8976059464 Fuel Injection Pump for Isuzu 6HK1 7.8L Engine FRR FSR FTR FVR FSS F Series Trucks

HIRINTOL 🔸Replace Part Number: 294050-0420, 294050-0421, 8976059464 || 🔸Engine Model: for Isuzu 6HK1 6HK1-TCC 6HK1-TCN 7.8L || 🔸Compatible Model: for Isuzu FRR FSR FTR FVR FSS F Series Trucks || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions.

HIRINTOL 🔸Replace Part Number: 294050-0420, 294050-0421, 8976059464 || 🔸Engine Model: for Isuzu 6HK1 6HK1-TCC 6HK1-TCN 7.8L || 🔸Compatible Model: for Isuzu FRR FSR FTR FVR FSS F Series Trucks || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions.

HP4 Common Rail Diesel Fuel Injection Feed Pump 8-97605946-5 294050-0420 294050-0421 294050-0422 For 6HK1

VWUNFRES Fuel delivery: the fuel pump pumps the fuel out of the fuel tank through negative pressure or positive pressure, and delivers it to the fuel injection system or carburetor of the engine through the fuel pipeline. || Improve fuel efficiency, reduce fuel waste, improve vehicle fuel economy, ensure engine performance, prolong engine life, protect engine fuel system, reduce engine wear caused by fuel pollution, adapt to different working conditions, and get the best fuel supply under different working conditions. || Sealing design: use our sealed high-pressure fuel pump to enjoy long-term leak-free operation. Small size: Our high-pressure fuel pump has a compact design, ensuring easy installation and saving space. High precision: Experience accurate fuel delivery with our high-pressure fuel pump specially designed for high precision. || To maintain the fuel pressure, the fuel pump needs to maintain a certain fuel pressure to ensure that the fuel can smoothly enter the combustion chamber of the engine. This is especially important for modern electronic fuel injection system, because fuel injection needs accurate fuel pressure to ensure the accuracy of fuel injection quantity. || HP4 Common Rail Diesel Fuel Injection Feed Pump 8-97605946-5 294050-0420 294050-0421 294050-0422 For 6HK1

VWUNFRES Fuel delivery: the fuel pump pumps the fuel out of the fuel tank through negative pressure or positive pressure, and delivers it to the fuel injection system or carburetor of the engine through the fuel pipeline. || Improve fuel efficiency, reduce fuel waste, improve vehicle fuel economy, ensure engine performance, prolong engine life, protect engine fuel system, reduce engine wear caused by fuel pollution, adapt to different working conditions, and get the best fuel supply under different working conditions. || Sealing design: use our sealed high-pressure fuel pump to enjoy long-term leak-free operation. Small size: Our high-pressure fuel pump has a compact design, ensuring easy installation and saving space. High precision: Experience accurate fuel delivery with our high-pressure fuel pump specially designed for high precision. || To maintain the fuel pressure, the fuel pump needs to maintain a certain fuel pressure to ensure that the fuel can smoothly enter the combustion chamber of the engine. This is especially important for modern electronic fuel injection system, because fuel injection needs accurate fuel pressure to ensure the accuracy of fuel injection quantity. || HP4 Common Rail Diesel Fuel Injection Feed Pump 8-97605946-5 294050-0420 294050-0421 294050-0422 For 6HK1

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00421 | 8-97605946 | PUMP ASSY, SUPPLY |

Information:

* Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps.* Inspect the fan and accessory drive belts for cracks, breaks or other damage. Belts for multiple groove pulleys are sold in matched sets. Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a two or three belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. The water pump seal is lubricated by coolant in the cooling system. It is normal for a small amount of leakage to occur as the engine cools down and parts contract. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, crankcase, oil filter and valve covers.* Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended service intervals prescribed in this publication until a leak is found or fixed, or until the suspicion for a leak has been proven to be unwarranted. * Inspect wiring for loose connections and worn or frayed wires.* Inspect air intake system hoses and elbows for cracks and loose clamps.* Inspect engine-to-frame ground strap for good connection and condition.Pre-Start Checks

* Measure the engine crankcase oil level. The correct oil level is shown by the marks between the words "ADD" and "FULL RANGE" on the dipstick (oil level gauge) on the "Engine Stopped" side.The location of the ADD and FULL RANGE marks on the engine dipstick are determined by the tilt angle of the engine after it is installed in the truck.If the ADD and FULL RANGE marks have not been stamped on the dipstick, see "Calibration" in the "Dipsticks" section of this manual or contact your authorized Caterpillar dealer. * Check the coolant level with the engine stopped and cold. Remove the filler cap slowly to relieve pressure.* Maintain the coolant level to within 1/2 inch (13 mm) of the bottom of the fill pipe. Install the filler cap.* If equipped with a sight glass, maintain the coolant to the proper level.

To prevent engine damage, never add coolant to an overheated engine. Allow the engine to cool first.

Typical Example* Observe the air cleaner service indicator (if equipped). Service the air cleaner when the yellow diaphragm enters the red zone or the red piston locks in the visible position. If your truck air cleaner is not equipped with an indicator, your authorized Caterpillar dealer can provide one for you.* Check fuel level. Do not fill fuel tank to top. Fuel expands as it gets warm and may overflow.

* Measure the engine crankcase oil level. The correct oil level is shown by the marks between the words "ADD" and "FULL RANGE" on the dipstick (oil level gauge) on the "Engine Stopped" side.The location of the ADD and FULL RANGE marks on the engine dipstick are determined by the tilt angle of the engine after it is installed in the truck.If the ADD and FULL RANGE marks have not been stamped on the dipstick, see "Calibration" in the "Dipsticks" section of this manual or contact your authorized Caterpillar dealer. * Check the coolant level with the engine stopped and cold. Remove the filler cap slowly to relieve pressure.* Maintain the coolant level to within 1/2 inch (13 mm) of the bottom of the fill pipe. Install the filler cap.* If equipped with a sight glass, maintain the coolant to the proper level.

To prevent engine damage, never add coolant to an overheated engine. Allow the engine to cool first.

Typical Example* Observe the air cleaner service indicator (if equipped). Service the air cleaner when the yellow diaphragm enters the red zone or the red piston locks in the visible position. If your truck air cleaner is not equipped with an indicator, your authorized Caterpillar dealer can provide one for you.* Check fuel level. Do not fill fuel tank to top. Fuel expands as it gets warm and may overflow.