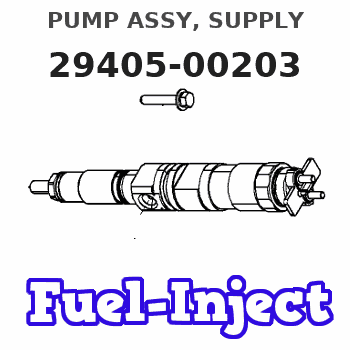

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel injection pump Fits for Hyundai D6GAD Engine HD120 HD170 HD500 Truck 294050-0204 33100-52001 33100-52000

KoovDem Part Number: 294050-0204 33100-52001 || Product Name: 294050-0204 33100-52001 Fuel injection pump || Compatible with Hyundai D6GAD engine, this product enhances HD120, HD170, and HD500 trucks' performance. Built for durability and optimal function, it is a reliable solution for maintaining and upgrading engine systems. Trust it to keep your Hyundai vehicle running smoothly and efficiently. || 1 unit of Fuel Injection Pump || . Our team will assist you in verifying the compatibility of the part with your engine. It is essential to ensure that you are purchasing the correct product to avoid any issues during installation or operation. Feel free to reach out to us for any assistance or clarification regarding the product or its compatibility with your engine. Your satisfaction is our priority. Thank you for your cooperation.

KoovDem Part Number: 294050-0204 33100-52001 || Product Name: 294050-0204 33100-52001 Fuel injection pump || Compatible with Hyundai D6GAD engine, this product enhances HD120, HD170, and HD500 trucks' performance. Built for durability and optimal function, it is a reliable solution for maintaining and upgrading engine systems. Trust it to keep your Hyundai vehicle running smoothly and efficiently. || 1 unit of Fuel Injection Pump || . Our team will assist you in verifying the compatibility of the part with your engine. It is essential to ensure that you are purchasing the correct product to avoid any issues during installation or operation. Feel free to reach out to us for any assistance or clarification regarding the product or its compatibility with your engine. Your satisfaction is our priority. Thank you for your cooperation.

Compatible with Hyundai Engine D6GAD Truck HD120 HD170 HD500 Fuel Injection Pump 294050-0204 33100-52001 33100-52000

KoovDem Part Number: 294050-0204 33100-52001 33100-52000 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || The D6GAD engine is a trusted diesel engine used in heavy machinery. Known for its durability, high performance, and fuel efficiency, it offers consistent power in tough conditions. Popular in construction, mining, and agriculture, it boasts advanced technology and a long lifespan. Ideal for those seeking reliable power for their equipment. || Suitable for use with the Hyundai Engine D6GAD Truck models HD120, HD170, and HD500. || Included in the package is one piece of Fuel Injection Pump with the part numbers 294050-0204, 33100-52001, and 33100-52000.

KoovDem Part Number: 294050-0204 33100-52001 33100-52000 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || The D6GAD engine is a trusted diesel engine used in heavy machinery. Known for its durability, high performance, and fuel efficiency, it offers consistent power in tough conditions. Popular in construction, mining, and agriculture, it boasts advanced technology and a long lifespan. Ideal for those seeking reliable power for their equipment. || Suitable for use with the Hyundai Engine D6GAD Truck models HD120, HD170, and HD500. || Included in the package is one piece of Fuel Injection Pump with the part numbers 294050-0204, 33100-52001, and 33100-52000.

IMIFAFTAbT High Pressure Pump 294050-0204 33100-52001 33100-52000 Fits for Hyundai D6GAD Engine HD120 HD170 HD500 Truck

IMIFAFTAbT Product Name: 294050-0204 33100-52001 High Pressure Pump || Part number: 294050-0204 33100-52001 || Fits for Hyundai D6GAD Engine HD120 HD170 HD500 Truck || 1 PCS High Pressure Pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 294050-0204 33100-52001 High Pressure Pump || Part number: 294050-0204 33100-52001 || Fits for Hyundai D6GAD Engine HD120 HD170 HD500 Truck || 1 PCS High Pressure Pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

You can express buy:

USD 441

13-05-2025

13-05-2025

Good Quality fuel pump assembly Common Rail fuel injection pumps 33100-52000 33100-52001 294050-0204

USD 1051.39

19-05-2025

19-05-2025

Fuel Pump 294050-0203 2940500203 33100-52001 294050-0280 22100-51041 294050-0282 22100-51042 294050-0283 22100-51042

Images:

USD 391.72

[14-Jun-2025]

USD 393.12

[14-Jun-2025]

USD 384.72

[14-Jun-2025]

USD 394.1

[29-May-2025]

Scheme ###:

| 000. | [01] | 29405-00203 | PUMP ASSY, SUPPLY | 3310052000 |

| 001. | [01] | 29410-05350 | HOUSING SUB-ASSY, | |

| 001. | [01] | 29410-05850 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 002. | [01] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15080 | CAMSHAFT, SUPPLY P | |

| 003. | [01] | 29419-15050 | CAMSHAFT, SUPPLY P | |

| 003. | [01] | 29419-15020 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | 3313345700 |

| 004. | [01] | 29402-10040 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05070 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [08] | 09644-90110 | BOLT, SOCKET | |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35020 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45000 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [05] | 09644-90050 | BOLT, SOCKET | |

| 015. | [01] | 29409-00340 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00360 | ELEMENT KIT, SUPPL | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 030. | [01] | 29409-00350 | ELEMENT KIT, SUPPL | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00670 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50010 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00130 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05020 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 043. | [01] | 09543-80170 | SCREW, HOLLOW | 3313745700 |

| 044. | [02] | 94901-02530 | WASHER | 3313745710 |

| 045. | [01] | 29409-90010 | COLLAR, FUEL OUTLE | |

| 046. | [01] | 94918-00310 | SCREW, HOLLOW | 3313645700 |

| 047. | [02] | 94901-02490 | WASHER | 3313645710 |

| 048. | [01] | 94919-80270 | COLLAR, PRESSBOARD | |

| 049. | [02] | 09031-70060 | PLUG, SCREW | |

| 050. | [02] | 09806-50020 | GASKET | |

| 051. | [01] | 29417-80120 | WASHER, CAMSHAFT | |

| 051. | [01] | 29417-80100 | WASHER, CAMSHAFT | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 055. | [01] | 94905-62390 | NUT | 3313245700 |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90050 | OVERHAUL KIT, SUPP |

Include in #3:

29405-00203

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00203 | 3310052000 | PUMP ASSY, SUPPLY |

Information:

Engine Oil (EO)

Caterpillar has an oil formulation to provide maximum performance and life in your truck engine.* Cat Engine Oil (EO)Cat Engine Oil (EO) is a lubricant that meets the performance requirements of today' newer truck engines as well as meeting the needs of earlier built truck engines. This oil has sufficient TBN and sulfated ash level to be effective in operation.This lubricating oil also meets the industry standards for both diesel and gasoline engine requirements.* Cat Diesel Engine Oil (DEO)Cat Diesel Engine Oil (DEO) may be used for current truck engines also. DEO provides the required performance for 3406B truck engines, however, it does not meet the API CE performance.Alternate Oils

Failure to follow these recommendations for CE performance oils can cause shortened engine life due to carbon deposits or excessive wear.

If an oil other than Cat oil is to be used, the following oil specifications provide selection guidelines: * API specifications CE, CE/SF, or CE/SGOil with these specifications may require shortened oil change periods as determined by close monitoring of oil condition with Scheduled Oil Sampling (S O S) and infrared analysis.Additional Notes

The percentage of sulfur in the fuel will affect the engine oil recommendations. For fuel sulfur effects, the Infrared Analysis and the ASTM D2896 procedure can be used to evaluate the residual neutralization properties of an engine oil. The sulfur products formation depends on the fuel sulfur content, oil formulation, crankcase blowby, engine operating conditions and ambient temperature.The Caterpillar 20 times rule for TBN versus fuel sulfur is a general requirement, but it can be modified by used oil analysis. The effectiveness of an oil formulation will depend on the additive package. A balanced additive package oil of a lower TBN can be as effective in fuel sulfur neutralization and overall performance as some oils with higher TBN values which have additives just for increased TBN. The used oil analysis can show these results.Consult the EMA Lubricating Oils Data Book, form SEBU6310 for a listing of oil brands meeting the CE requirements.For more information on oil and fuel sulfur content, refer to "Oil and Your Engine," form SEBD0640.Always consult with your Caterpillar dealer for the latest lubrication recommendations.Anti-Seize Compound (ASC)

Use 5P3931 Anti-Seize Compound (ASC) or equivalent.Cat Lubricating Grease

Caterpillar has greases for all applications.* Cat Multipurpose Lithium Grease (MPGL) (non-extreme pressure)This NLGI No. 2 grade is recommended for light duty automotive type applications where a high temperature [up to 175°C (350°F)] is required. This grease offers excellent mechanical stability, high resistance to oxidation, good rust protection and excellent breakaway torque.If this grease is not available, use a similar multipurpose grease.* Cat Special Purpose Grease (SPG)This grease is recommended for high temperature anti-friction bearings in such applications as electric motors, alternators, starters and generators. The grease is a NLGI No. 2 grade.This NLGI No. 2 grade is suitable for most temperatures [-28°C to +149°C (-18°F to +300°F)]. Use NLGI No. 1 or No. 0 grade for extremely low temperature.If this grease is not available, use a similar

Caterpillar has an oil formulation to provide maximum performance and life in your truck engine.* Cat Engine Oil (EO)Cat Engine Oil (EO) is a lubricant that meets the performance requirements of today' newer truck engines as well as meeting the needs of earlier built truck engines. This oil has sufficient TBN and sulfated ash level to be effective in operation.This lubricating oil also meets the industry standards for both diesel and gasoline engine requirements.* Cat Diesel Engine Oil (DEO)Cat Diesel Engine Oil (DEO) may be used for current truck engines also. DEO provides the required performance for 3406B truck engines, however, it does not meet the API CE performance.Alternate Oils

Failure to follow these recommendations for CE performance oils can cause shortened engine life due to carbon deposits or excessive wear.

If an oil other than Cat oil is to be used, the following oil specifications provide selection guidelines: * API specifications CE, CE/SF, or CE/SGOil with these specifications may require shortened oil change periods as determined by close monitoring of oil condition with Scheduled Oil Sampling (S O S) and infrared analysis.Additional Notes

The percentage of sulfur in the fuel will affect the engine oil recommendations. For fuel sulfur effects, the Infrared Analysis and the ASTM D2896 procedure can be used to evaluate the residual neutralization properties of an engine oil. The sulfur products formation depends on the fuel sulfur content, oil formulation, crankcase blowby, engine operating conditions and ambient temperature.The Caterpillar 20 times rule for TBN versus fuel sulfur is a general requirement, but it can be modified by used oil analysis. The effectiveness of an oil formulation will depend on the additive package. A balanced additive package oil of a lower TBN can be as effective in fuel sulfur neutralization and overall performance as some oils with higher TBN values which have additives just for increased TBN. The used oil analysis can show these results.Consult the EMA Lubricating Oils Data Book, form SEBU6310 for a listing of oil brands meeting the CE requirements.For more information on oil and fuel sulfur content, refer to "Oil and Your Engine," form SEBD0640.Always consult with your Caterpillar dealer for the latest lubrication recommendations.Anti-Seize Compound (ASC)

Use 5P3931 Anti-Seize Compound (ASC) or equivalent.Cat Lubricating Grease

Caterpillar has greases for all applications.* Cat Multipurpose Lithium Grease (MPGL) (non-extreme pressure)This NLGI No. 2 grade is recommended for light duty automotive type applications where a high temperature [up to 175°C (350°F)] is required. This grease offers excellent mechanical stability, high resistance to oxidation, good rust protection and excellent breakaway torque.If this grease is not available, use a similar multipurpose grease.* Cat Special Purpose Grease (SPG)This grease is recommended for high temperature anti-friction bearings in such applications as electric motors, alternators, starters and generators. The grease is a NLGI No. 2 grade.This NLGI No. 2 grade is suitable for most temperatures [-28°C to +149°C (-18°F to +300°F)]. Use NLGI No. 1 or No. 0 grade for extremely low temperature.If this grease is not available, use a similar