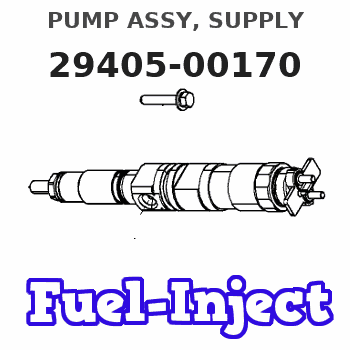

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Fuel Injection Pump 294050-0170 294050-0171 ME304719 ME306389 Compatible For MITSUBISHI 6M60T

VXRWKZEO Diesel Fuel Injection Pump 294050-0170 294050-0171 ME304719 ME306389 Compatible For MITSUBISHI 6M60T || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

VXRWKZEO Diesel Fuel Injection Pump 294050-0170 294050-0171 ME304719 ME306389 Compatible For MITSUBISHI 6M60T || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

DoraKvi Fuel Injection Pump 294050-0170 294050-0171 ME306389 Compatible with Mitsubishi Engine 6M60T Truck Fuso FK260

DoraKvi 🌟 Part Name : Fuel Injection Pump || 🌟 Part Number :294050-0170, 294050-0171, 294050-0172, ME306389, ME304719, 2940500170, 2940500171, 2940500172 || 🌟 Application : Compatible with Mitsubishi Engine 6M60T Truck Fuso FK260 || ✅ Accurate ✅- In Order To Avoid Unnecessary Returnplease. Please follow the old part number and machine model to find the right product, if you are not sure, please contact us, we are more than happy to provide services. || 💠 Reliable performance 💠- DoraKvi - our products have been carefully designed and tested, with high reliability and stability, can maintain good working condition for a long time.

DoraKvi 🌟 Part Name : Fuel Injection Pump || 🌟 Part Number :294050-0170, 294050-0171, 294050-0172, ME306389, ME304719, 2940500170, 2940500171, 2940500172 || 🌟 Application : Compatible with Mitsubishi Engine 6M60T Truck Fuso FK260 || ✅ Accurate ✅- In Order To Avoid Unnecessary Returnplease. Please follow the old part number and machine model to find the right product, if you are not sure, please contact us, we are more than happy to provide services. || 💠 Reliable performance 💠- DoraKvi - our products have been carefully designed and tested, with high reliability and stability, can maintain good working condition for a long time.

Diesel Fuel Injection Pump 294050-0170 294050-0171 ME304719 ME306389 Compatible For MITSUBISHI 6M60T

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || Diesel Fuel Injection Pump 294050-0170 294050-0171 ME304719 ME306389 Compatible For MITSUBISHI 6M60T

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || Diesel Fuel Injection Pump 294050-0170 294050-0171 ME304719 ME306389 Compatible For MITSUBISHI 6M60T

You can express buy:

Images:

USD 410.72

[19-May-2025]

USD 384.18

[19-May-2025]

USD 466.6

[19-May-2025]

USD 406.95

[19-May-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29405-00170 |

| 001. | PUMP ASSY, SUPPLY | 29405-00170 |

| 002. | OVERHAUL KIT, SUPP | 29400-90050 |

Scheme ###:

| 000. | [01] | 29405-00170 | PUMP ASSY, SUPPLY | ME304719 |

| 000. | [01] | 29405-00171 | PUMP ASSY, SUPPLY | ME306389 |

| 001. | [01] | 29410-05191 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15010 | CAMSHAFT, SUPPLY P | |

| 003. | [01] | 29419-15090 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10040 | KEY, WOODRUFF | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05000 | RING SUB-ASSY, CAM | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05030 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05070 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [08] | 09644-90110 | BOLT, SOCKET | ME736324 |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35030 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45010 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [03] | 09644-90050 | BOLT, SOCKET | |

| 015. | [01] | 29409-00350 | ELEMENT KIT, SUPPL | |

| 015. | [01] | 29409-00620 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00340 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00710 | ELEMENT KIT, SUPPL | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 021. | [01] | 29409-00360 | ELEMENT KIT, SUPPL | |

| 021. | [01] | 29409-00630 | ELEMENT KIT, SUPPL | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00180 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60030 | O-RING, VALVE | |

| 034. | [01] | 29428-50040 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00200 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05050 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 041. | [01] | 09543-80170 | SCREW, HOLLOW | ME743860 |

| 042. | [02] | 94901-02530 | WASHER | ME743814 |

| 044. | [01] | 94918-00310 | SCREW, HOLLOW | ME702236 |

| 045. | [02] | 94901-02490 | WASHER | ME743859 |

| 047. | [01] | 09031-70060 | PLUG, SCREW | ME702176 |

| 048. | [01] | 09806-50020 | GASKET | |

| 050. | [01] | 29425-90020 | GASKET, SOLENOID | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 053. | [01] | 94919-80260 | COLLAR, PRESSBOARD | ME702848 |

| 054. | [01] | 94919-80270 | COLLAR, PRESSBOARD | ME702632 |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90050 | OVERHAUL KIT, SUPP |

Include in #3:

29405-00170

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00170 | ME304719 | PUMP ASSY, SUPPLY | |

| ME304719 | MITSUBISHI | PUMP ASSY SUPPLY | |

| ME304719 | MITSUBISHI | PUMP ASSY, SUPPLY | |

| ME306389 | MITSUBISHI | PUMP ASSY, SUPPLY |

Information:

Auxiliary engine braking devices are approved for use on the 3406B Engine.Compression Brake

Operation (Jacobs Brake or Pacific Brake)

The Jacobs Engine Brake should not be used as a primary or service brake. Do not allow the engine to exceed 2300 rpm. However, engines equipped with a Jacobs Engine Brake should not normally be operated above 2100 rpm.

The Jacobs Engine Brake is an engine attachment that converts a diesel engine into an air compressor. Its function is to slow the vehicle and reduce brake wear.Operating Controls-Compression Brake

The Jacobs Engine Brake controls may include a dash mounted module or an ON/OFF switch and a three position switch with "Lo," "Med" and "Hi" depending on how many cylinders of braking desired.On some applications a multiposition switch is used to provide variable retarding capability. Operators should become familiar with the controls used on their vehicles. Refer to the OEM vehicle manual for the type of operating controls that your vehicle is equipped with.Since the Jacobs Engine Brake is most effective at rated engine rpm, gear selection is very important. Gearing down the vehicle, within the limits of rated engine rpm, makes the engine brake a more effective retarder. Maximum retarding occurs at higher engine rpm.For information on adjustment to Jacobs Brake slave piston lash, refer to PM Level 2-Engine Valve Lash. Refer to Jacobs Brake Troubleshooting Manual, Form SENR4251 for information regarding this auxiliary braking system.There are differences in exhaust braking devices from those with little or no leakage when activated to those with a great deal of leakage.Sliding Gate Type (Williams Blue Ox)

This type of exhaust brake allows minimal leakage and must have a relief orifice to limit the maximum exhaust manifold back pressure to 50 psi (345 kPa) at maximum engine braking rpm. Flapper Type (Pacific)

With this type of exhaust brake, there is usually leakage around the movable plate. To obtain 50 psi (345 kPa) or 70 psi (485 kPa) performance level braking, a small hole would likely be required. The maximum permissible exhaust back pressure at maximum engine braking rpm is measured at the 1/4 NPT hole in the exhaust manifold below the turbocharger.Refer to the April, 1988 "Truck Engine Application and Installation Guide," Form LEBT8121

Operation (Jacobs Brake or Pacific Brake)

The Jacobs Engine Brake should not be used as a primary or service brake. Do not allow the engine to exceed 2300 rpm. However, engines equipped with a Jacobs Engine Brake should not normally be operated above 2100 rpm.

The Jacobs Engine Brake is an engine attachment that converts a diesel engine into an air compressor. Its function is to slow the vehicle and reduce brake wear.Operating Controls-Compression Brake

The Jacobs Engine Brake controls may include a dash mounted module or an ON/OFF switch and a three position switch with "Lo," "Med" and "Hi" depending on how many cylinders of braking desired.On some applications a multiposition switch is used to provide variable retarding capability. Operators should become familiar with the controls used on their vehicles. Refer to the OEM vehicle manual for the type of operating controls that your vehicle is equipped with.Since the Jacobs Engine Brake is most effective at rated engine rpm, gear selection is very important. Gearing down the vehicle, within the limits of rated engine rpm, makes the engine brake a more effective retarder. Maximum retarding occurs at higher engine rpm.For information on adjustment to Jacobs Brake slave piston lash, refer to PM Level 2-Engine Valve Lash. Refer to Jacobs Brake Troubleshooting Manual, Form SENR4251 for information regarding this auxiliary braking system.There are differences in exhaust braking devices from those with little or no leakage when activated to those with a great deal of leakage.Sliding Gate Type (Williams Blue Ox)

This type of exhaust brake allows minimal leakage and must have a relief orifice to limit the maximum exhaust manifold back pressure to 50 psi (345 kPa) at maximum engine braking rpm. Flapper Type (Pacific)

With this type of exhaust brake, there is usually leakage around the movable plate. To obtain 50 psi (345 kPa) or 70 psi (485 kPa) performance level braking, a small hole would likely be required. The maximum permissible exhaust back pressure at maximum engine braking rpm is measured at the 1/4 NPT hole in the exhaust manifold below the turbocharger.Refer to the April, 1988 "Truck Engine Application and Installation Guide," Form LEBT8121