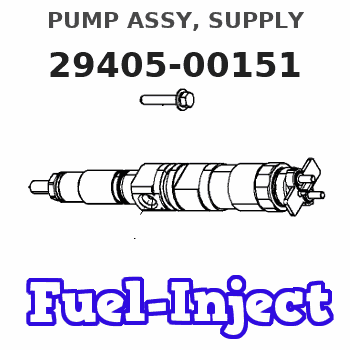

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Compatible with Hino 268 Medium Duty Truck Diesel Engine J08E Fuel Injection Pump 22100-E0101 294050-0151 2940500151 22100E0101

KoovDem Part Name: Fuel Injection Pump || Part Number: 22100-E0101 294050-0151 || The J08E engine is a powerful and reliable option for heavy-duty commercial vehicles, delivering high torque and horsepower with advanced technology. It is fuel-efficient and environmentally friendly, with durable construction for long-lasting performance. Ideal for trucking applications, the J08E engine provides the strength and reliability needed to tackle tough jobs efficiently. || This product is designed to be fully compatible with the Hino 268 Medium Duty Truck Diesel Engine J08E, meeting its specific requirements for optimal performance and reliability. Whether you need a replacement or upgrade, trust in this product to seamlessly integrate and enhance your Hino 268's efficiency and power. || Please provide your physical address (either your home or office address), and please do not use a P.O. box address.

KoovDem Part Name: Fuel Injection Pump || Part Number: 22100-E0101 294050-0151 || The J08E engine is a powerful and reliable option for heavy-duty commercial vehicles, delivering high torque and horsepower with advanced technology. It is fuel-efficient and environmentally friendly, with durable construction for long-lasting performance. Ideal for trucking applications, the J08E engine provides the strength and reliability needed to tackle tough jobs efficiently. || This product is designed to be fully compatible with the Hino 268 Medium Duty Truck Diesel Engine J08E, meeting its specific requirements for optimal performance and reliability. Whether you need a replacement or upgrade, trust in this product to seamlessly integrate and enhance your Hino 268's efficiency and power. || Please provide your physical address (either your home or office address), and please do not use a P.O. box address.

Compatible with Hino J08E Engine Fuel Injection Pump 294050-0150 294050-0151 294050-0153

KoovDem Part Name :Fuel Injection Pump || Part Number:294050-0150 294050-0151 294050-0153 || Designed to seamlessly work with the Hino J08E Engine, this application is compatible with a variety of vehicles and machinery. Engineered to meet specific requirements and standards, it ensures smooth operation and reliability in industrial and commercial settings. Utilizing the latest technology in engine design, it provides users with a durable and dependable solution for their equipment needs. || Accurate - To prevent unnecessary returns, it is important to refer to the old part number and machine model when ordering the correct product. If unsure, please contact us for assistance as we are committed to providing excellent customer service. || Our products are designed and tested to ensure reliable performance. With high reliability and stability, they can maintain optimal working conditions for extended periods of time.

KoovDem Part Name :Fuel Injection Pump || Part Number:294050-0150 294050-0151 294050-0153 || Designed to seamlessly work with the Hino J08E Engine, this application is compatible with a variety of vehicles and machinery. Engineered to meet specific requirements and standards, it ensures smooth operation and reliability in industrial and commercial settings. Utilizing the latest technology in engine design, it provides users with a durable and dependable solution for their equipment needs. || Accurate - To prevent unnecessary returns, it is important to refer to the old part number and machine model when ordering the correct product. If unsure, please contact us for assistance as we are committed to providing excellent customer service. || Our products are designed and tested to ensure reliable performance. With high reliability and stability, they can maintain optimal working conditions for extended periods of time.

CR HP4 Fuel Injection Pump for Hino J08E Engine Medium Heavy Duty Truck 294050-0151 294050-0152 294050-0153 22100-E0102 22100-E0101

KoovDem Part Number: 294050-0151 294050-0152 294050-0153 22100-E0102 22100-E0101 || Vehicle Application:For Hino Medium Heavy Duty Truck || Model for Hino J08E Engine is a durable and powerful option for heavy-duty vehicles, offering exceptional performance and efficiency. Known for its longevity and reliability, this engine meets industry standards with advanced technology and superior engineering. Whether for commercial trucks, buses, or construction equipment, it delivers consistent power to keep your vehicle running smoothly. Trust in the Model for Hino J08E Engine for a dependable driving experience. || for verification. This will help ensure that you receive the correct part for your vehicle. It is important to double check the accuracy of the part numbers to avoid any delays or inconvenience. Thank you for your attention to detail and for choosing our services. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

KoovDem Part Number: 294050-0151 294050-0152 294050-0153 22100-E0102 22100-E0101 || Vehicle Application:For Hino Medium Heavy Duty Truck || Model for Hino J08E Engine is a durable and powerful option for heavy-duty vehicles, offering exceptional performance and efficiency. Known for its longevity and reliability, this engine meets industry standards with advanced technology and superior engineering. Whether for commercial trucks, buses, or construction equipment, it delivers consistent power to keep your vehicle running smoothly. Trust in the Model for Hino J08E Engine for a dependable driving experience. || for verification. This will help ensure that you receive the correct part for your vehicle. It is important to double check the accuracy of the part numbers to avoid any delays or inconvenience. Thank you for your attention to detail and for choosing our services. || Service: We offer a 6-month warranty and 24-hour customer support for all products. If you have any questions or concerns, please don't hesitate to reach out to us via email.

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00151 | 22100-E010 | PUMP ASSY, SUPPLY |

Information:

Safety

The safety section lists basic safety precautions. In addition, this section identifies the text and locations of warning labels used on the engine.Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and repair on this product.Operation

Illustrations guide the operator through correct procedures of checking, starting, operating and stopping the engine.The operation section is a reference for the new operator and a refresher for the experienced one.The operating sections outlined in this publication are organized to assist you with developing the skills and techniques required to operate your engine more efficiently and economically.Maintenance

The maintenance section is a guide to equipment care. The illustrated, step-by-step instructions are grouped by Preventive Maintenance servicing intervals. Items in the "Maintenance Management Schedule" are referenced to detailed instructions that follow.The "Maintenance Management Schedule" items are organized for a Preventive Maintenance Program.If the Preventive Maintenance Program is followed, a periodic tune-up is not required. The implementation of a Preventive Maintenance Management Program should minimize operating costs through cost avoidances resulting from reductions in unscheduled downtime and failures.Maintenance Intervals

The service interval for each item listed in the "Maintenance Management Schedule" is primarily based on the item and its relationship to either engine speed or load.We recommend that these schedules be reproduced for ease of inspection. We also recommend that a maintenance record be maintained as part of the equipment's permanent record.See the "Maintenance Log" section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair.Your authorized Caterpillar dealer can assist you in tailoring your schedule to meet the needs of your operating environment.

The safety section lists basic safety precautions. In addition, this section identifies the text and locations of warning labels used on the engine.Read and understand the basic precautions listed in the safety section before operating or performing lubrication, maintenance and repair on this product.Operation

Illustrations guide the operator through correct procedures of checking, starting, operating and stopping the engine.The operation section is a reference for the new operator and a refresher for the experienced one.The operating sections outlined in this publication are organized to assist you with developing the skills and techniques required to operate your engine more efficiently and economically.Maintenance

The maintenance section is a guide to equipment care. The illustrated, step-by-step instructions are grouped by Preventive Maintenance servicing intervals. Items in the "Maintenance Management Schedule" are referenced to detailed instructions that follow.The "Maintenance Management Schedule" items are organized for a Preventive Maintenance Program.If the Preventive Maintenance Program is followed, a periodic tune-up is not required. The implementation of a Preventive Maintenance Management Program should minimize operating costs through cost avoidances resulting from reductions in unscheduled downtime and failures.Maintenance Intervals

The service interval for each item listed in the "Maintenance Management Schedule" is primarily based on the item and its relationship to either engine speed or load.We recommend that these schedules be reproduced for ease of inspection. We also recommend that a maintenance record be maintained as part of the equipment's permanent record.See the "Maintenance Log" section of this publication for information regarding documents that are generally accepted as proof of maintenance or repair.Your authorized Caterpillar dealer can assist you in tailoring your schedule to meet the needs of your operating environment.