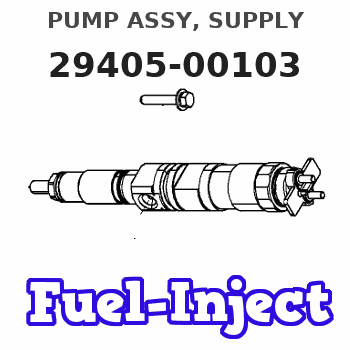

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

IMIFAFTAbT 8-98091565-0 8-98091565-1 8-98091565-2 Fuel Injection Pump HP4 Fits For Isuzu 6HK1 7.8L Engine FRR FSR FTR FVR FSS NPR NQR NRR Trucks Fits For Hitachi ZX330-3 ZX330-5A Excavator

IMIFAFTAbT Part Name:Fuel Injection Pump 294050-0105 294050-0103 || Part Number:8-98091565-0 8-98091565-1 8-98091565-2 || APPlication: Compatible For Isuzu 6HK1 7.8L Engine FRR FSR FTR FVR FSS NPR NQR NRR Trucks Compatible For Hitachi ZAX330-3 ZAX350-3 ZAX360-3 Excavator || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

IMIFAFTAbT Part Name:Fuel Injection Pump 294050-0105 294050-0103 || Part Number:8-98091565-0 8-98091565-1 8-98091565-2 || APPlication: Compatible For Isuzu 6HK1 7.8L Engine FRR FSR FTR FVR FSS NPR NQR NRR Trucks Compatible For Hitachi ZAX330-3 ZAX350-3 ZAX360-3 Excavator || If you are not sure if the product is suitable please leave us a message and send us your original || product picture and part number and we will send the correct part after confirmation

HP4 Fuel Injection Pump Compatible with Isuzu 6HK1 7.8L Engine FRR FSR FTR FVR FSS NPR NQR NRR Trucks Hitachi ZAX330-3 ZAX350-3 ZAX360-3 294050-0105 294050-0103 294050-0100 8-98091565-2 8-98091565-3

KoovDem Part Number: 294050-0105, 294050-0104, 294050-0103, 294050-0102, 294050-0101, 294050-0100. || Part Number: 8-98091565-0, 8-98091565-1, 8-98091565-2, 8-98091565-3, 8-98091565-4, 8-98091565-5, 8-98091565-6, 8-98091565-7, 8-98091565-8, 8-98091565-9. || This application is suitable for Isuzu 6HK1 7.8L engine models used in a variety of trucks including the FRR, FSR, FTR, FVR, FSS, NPR, NQR, and NRR. It can also be used in Hitachi ZAX330-3, ZAX350-3, ZAX360-3, SH350A5, SH300, SH360, CX350B, and JCB360 excavators. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

KoovDem Part Number: 294050-0105, 294050-0104, 294050-0103, 294050-0102, 294050-0101, 294050-0100. || Part Number: 8-98091565-0, 8-98091565-1, 8-98091565-2, 8-98091565-3, 8-98091565-4, 8-98091565-5, 8-98091565-6, 8-98091565-7, 8-98091565-8, 8-98091565-9. || This application is suitable for Isuzu 6HK1 7.8L engine models used in a variety of trucks including the FRR, FSR, FTR, FVR, FSS, NPR, NQR, and NRR. It can also be used in Hitachi ZAX330-3, ZAX350-3, ZAX360-3, SH350A5, SH300, SH360, CX350B, and JCB360 excavators. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

Compatible with Isuzu Engine 6HK1 Excavator ZAX330-3 ZAX350-3 ZAX360-3 SH350A5 SH300 SH360 Fuel Injection Pump 8-98091565-3 294050-0105 294050-0103 8-98091565-2

KoovDem Part Number:16030-51052 16030-51053 1603051052 || Part Name: Fuel Injection Pump || The S1200 engine, renowned for its versatility and efficiency, is commonly found in marine vessels, backup power systems, and industrial machinery. With a 1.2-liter capacity, it delivers exceptional performance while minimizing fuel usage. Its durable build and minimal maintenance needs make it a popular choice for various applications, ensuring reliable and long-lasting operation. || Compatible with Kubota Engine models D905, D1005, D1105, and D1305, this product is specifically designed for optimal performance and reliability. It is engineered to seamlessly integrate with these engines, providing a seamless fit and reliable operation. Whether for industrial or agricultural applications, this product is a perfect choice for ensuring smooth and efficient operation with your Kubota engine. || Suitable for use with Kubota tractor models B2301, B2601, B2320, B2620, B2920, and BX2680, in addition to utility vehicles RTV-X1100, RTV-X1120, and RTV-X1140.

KoovDem Part Number:16030-51052 16030-51053 1603051052 || Part Name: Fuel Injection Pump || The S1200 engine, renowned for its versatility and efficiency, is commonly found in marine vessels, backup power systems, and industrial machinery. With a 1.2-liter capacity, it delivers exceptional performance while minimizing fuel usage. Its durable build and minimal maintenance needs make it a popular choice for various applications, ensuring reliable and long-lasting operation. || Compatible with Kubota Engine models D905, D1005, D1105, and D1305, this product is specifically designed for optimal performance and reliability. It is engineered to seamlessly integrate with these engines, providing a seamless fit and reliable operation. Whether for industrial or agricultural applications, this product is a perfect choice for ensuring smooth and efficient operation with your Kubota engine. || Suitable for use with Kubota tractor models B2301, B2601, B2320, B2620, B2920, and BX2680, in addition to utility vehicles RTV-X1100, RTV-X1120, and RTV-X1140.

You can express buy:

USD 907.29

13-05-2025

13-05-2025

Excavator Spare Parts High Pressure Common Rail Diesel Fuel Injection Pump 8-98091565-3 294050-0103 for ISUZU 6HK1 Engine

USD 536.47

19-05-2025

19-05-2025

CR HP4 Fuel Injection Pump 294050-0105 294050-0103 8-98091565-3 8-98091565-1 For Isuzu 6HK1 7.8L Engine Medium Heavy Duty Truck

Images:

USD 2256.4

[29-Apr-2025]

USD 384.18

[19-May-2025]

USD 477.02

[01-Jun-2025]

USD 461.01

[30-May-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00103 | 8-98091565 | PUMP ASSY, SUPPLY |

Information:

Air Compressor

Rebuild or Exchange

Visually check for fluid leaks.Our recommendation to maintain your air compressor before it fails will be less costly than repairing the air compressor after failure.If the engine is operated until the air compressor fails, additional damage to the engine could result. For example: A failed air compressor could contaminate the engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these contaminates through the engine lubricating system could damage the engine's main and connecting rod bearings.Maintenance Options

Repair Kits - These useful kits can be obtained from your Caterpillar dealer. These kits include all the necessary parts, special tools and instructions to repair your air compressor in either your own maintenance shop or at your servicing dealer's facility. Repair kits simplify parts ordering, help speed repairs and reduce parts cost. Exchange - This is a cost cutting service that permits exchanging a worn air compressor for a dealer or OEM factory rebuilt air compressor on an over-the-counter basis. They are available when needed at a substantial savings in both time and money. New - Replace with a new air compressor.Caterpillar Recommendation

The most cost effective repair option is to rebuild the air compressor with a repair kit that can be obtained from your Caterpillar dealer.Refer to the Service Manual for your engine to remove and install the air compressor.Turbocharger

Rebuild or Exchange

The cost incurred to maintain your turbocharger before failure as recommended could be significantly less than if you wait until your turbocharger fails.By maintaining your turbocharger before failure, you will minimize unscheduled downtime and reduce the chances for potential damage to other engine parts. When you reduce the risk of unscheduled downtime and costly repairs, you conserve cash that can be budgeted for use more profitably elsewhere.If you choose to operate your engine until the turbocharger fails, your repair costs could be as much as twenty-five times or more compared to the repair before failure cost. This excessive cost is due to additional engine damage that could have been prevented.If the engine is operated until the turbocharger fails, severe damage to the turbocharger's compressor wheel and/or engine could result.For example: severe damage to the turbocharger compressor wheel could cause parts from the compressor wheel to enter the engine cylinder that could result in cracks in the cylinder head and cause additional damage to the piston, a piston seizure orother potential damage to valves and cylinder head.Our recommended maintenance intervals for performing preventive maintenance on your turbocharger are based on experience and gathered data relative to the expectant life of the engine and its components. These maintenance intervals were developed as a service for your use to minimize unexpected and costly repairs as well as to serve as an aid to reduce your operating costs.Failure to follow our recommendations could result in unexpected, costly repairs and unscheduled downtime.Caterpillar recommends that the most cost

Rebuild or Exchange

Visually check for fluid leaks.Our recommendation to maintain your air compressor before it fails will be less costly than repairing the air compressor after failure.If the engine is operated until the air compressor fails, additional damage to the engine could result. For example: A failed air compressor could contaminate the engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these engine oil with particles of materials since engine oil also lubricates the air compressor. The circulation of these contaminates through the engine lubricating system could damage the engine's main and connecting rod bearings.Maintenance Options

Repair Kits - These useful kits can be obtained from your Caterpillar dealer. These kits include all the necessary parts, special tools and instructions to repair your air compressor in either your own maintenance shop or at your servicing dealer's facility. Repair kits simplify parts ordering, help speed repairs and reduce parts cost. Exchange - This is a cost cutting service that permits exchanging a worn air compressor for a dealer or OEM factory rebuilt air compressor on an over-the-counter basis. They are available when needed at a substantial savings in both time and money. New - Replace with a new air compressor.Caterpillar Recommendation

The most cost effective repair option is to rebuild the air compressor with a repair kit that can be obtained from your Caterpillar dealer.Refer to the Service Manual for your engine to remove and install the air compressor.Turbocharger

Rebuild or Exchange

The cost incurred to maintain your turbocharger before failure as recommended could be significantly less than if you wait until your turbocharger fails.By maintaining your turbocharger before failure, you will minimize unscheduled downtime and reduce the chances for potential damage to other engine parts. When you reduce the risk of unscheduled downtime and costly repairs, you conserve cash that can be budgeted for use more profitably elsewhere.If you choose to operate your engine until the turbocharger fails, your repair costs could be as much as twenty-five times or more compared to the repair before failure cost. This excessive cost is due to additional engine damage that could have been prevented.If the engine is operated until the turbocharger fails, severe damage to the turbocharger's compressor wheel and/or engine could result.For example: severe damage to the turbocharger compressor wheel could cause parts from the compressor wheel to enter the engine cylinder that could result in cracks in the cylinder head and cause additional damage to the piston, a piston seizure orother potential damage to valves and cylinder head.Our recommended maintenance intervals for performing preventive maintenance on your turbocharger are based on experience and gathered data relative to the expectant life of the engine and its components. These maintenance intervals were developed as a service for your use to minimize unexpected and costly repairs as well as to serve as an aid to reduce your operating costs.Failure to follow our recommendations could result in unexpected, costly repairs and unscheduled downtime.Caterpillar recommends that the most cost