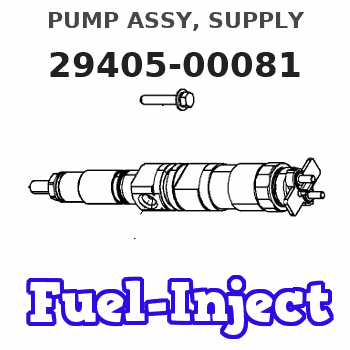

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

HP4 Diesel Fuel Common Rail Injection Pump 294050-0080 294050-0081 22730-1341 S2273-01341 16730Z503 Compatible For Hino J08E Engine

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

Diesel Fuel Injection Pump Hp4 22730-1340 294050-0081

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

HP4 Diesel fuel Common Rail injection pump 294050-0080 294050-0081 22730-1341 S2273-01341 16730Z503 Compatible for Hino J08E Engine

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

You can express buy:

USD 399.26

01-06-2025

01-06-2025

HP4 Diesel fuel Common Rail injection pump 294050-0080 294050-0081 22730-1341 S2273-01341 16730Z503 For Hino J08E Engine

Images:

USD 460.02

[30-May-2025]

USD 384.18

[19-May-2025]

USD 27.28

[28-Apr-2025]

USD 537.58

[20-May-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29405-00081 |

| 001. | PUMP ASSY, SUPPLY | 29405-00081 |

| 001. | PUMP ASSY, SUPPLY | 29405-00081 |

| 001. | PUMP ASSY, SUPPLY | 29405-00081 |

| 002. | OVERHAUL KIT, SUPP | 29400-90051 |

Scheme ###:

| 000. | [01] | 29405-00080 | PUMP ASSY, SUPPLY | 22730-1340 |

| 000. | [01] | 29405-00081 | PUMP ASSY, SUPPLY | 22730-1341 |

| 000. | [01] | 29405-00081 | PUMP ASSY, SUPPLY | S2273-01341 |

| 000. | [01] | 29405-00081 | PUMP ASSY, SUPPLY | 16730Z503B |

| 000. | [01] | 29405-00080 | PUMP ASSY, SUPPLY | 16730Z501B |

| 001. | [01] | 29410-05101 | HOUSING SUB-ASSY, | |

| 001. | [01] | 29410-05101 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15000 | CAMSHAFT, SUPPLY P | |

| 003. | [01] | 29419-15000 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05000 | RING SUB-ASSY, CAM | |

| 005. | [01] | 29417-05000 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05030 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05030 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [08] | 09644-90110 | BOLT, SOCKET | |

| 007. | [08] | 29419-90050 | BOLT, SOCKET | |

| 007. | [08] | 09644-90110 | BOLT, SOCKET | |

| 007. | [08] | 29419-90050 | BOLT, SOCKET | |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35020 | PLATE, FEED PUMP, | |

| 010. | [01] | 29418-35020 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45000 | COVER, FEED PUMP | |

| 011. | [01] | 29418-45000 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [03] | 09644-90050 | BOLT, SOCKET | |

| 014. | [03] | 29419-90040 | BOLT, SOCKET | |

| 014. | [03] | 09644-90050 | BOLT, SOCKET | |

| 014. | [03] | 29419-90040 | BOLT, SOCKET | |

| 015. | [01] | 29409-00240 | ELEMENT KIT, SUPPL | |

| 015. | [01] | 29409-00240 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00250 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00250 | ELEMENT KIT, SUPPL | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90060 | BOLT, SOCKET | |

| 020. | [12] | 29419-90060 | BOLT, SOCKET | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 021. | [01] | 29409-00230 | ELEMENT KIT, SUPPL | |

| 021. | [01] | 29409-00230 | ELEMENT KIT, SUPPL | |

| 022. | [03] | 29419-80020 | O-RING, SUPPLY PUM | |

| 022. | [03] | 29419-80020 | O-RING, SUPPLY PUM | |

| 023. | [03] | 29413-50011 | PLUG, CYLINDER | |

| 023. | [03] | 29413-50011 | PLUG, CYLINDER | |

| 024. | [03] | 29414-00110 | VALVE SUB-ASSY, SU | |

| 024. | [03] | 29414-00110 | VALVE SUB-ASSY, SU | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00140 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00190 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00190 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60030 | O-RING, VALVE | |

| 033-001. | [01] | 29428-60030 | O-RING, VALVE | |

| 034. | [01] | 29428-50040 | O-RING, SOLENOID | |

| 034. | [01] | 29428-50040 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00130 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00130 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05020 | PIPE, SUPPLY PUMP | |

| 036. | [02] | 29401-05020 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 040. | [01] | 29425-90020 | GASKET, SOLENOID | |

| 040. | [01] | 29425-90020 | GASKET, SOLENOID | |

| 043. | [01] | 94918-00060 | SCREW, HOLLOW | 22835-1110A |

| 043. | [01] | 94918-00060 | SCREW, HOLLOW | 16753Z6000 |

| 044. | [02] | 94901-02470 | WASHER | |

| 044. | [02] | 94901-02470 | WASHER | 22847-1900A |

| 045. | [01] | 94919-80260 | COLLAR, PRESSBOARD | 22332-1650A |

| 045. | [01] | 94919-80260 | COLLAR, PRESSBOARD | |

| 046. | [01] | 94918-00310 | SCREW, HOLLOW | 16753Z6002 |

| 046. | [01] | 94918-00310 | SCREW, HOLLOW | S2283-51310-A |

| 047. | [02] | 94901-02490 | WASHER | |

| 047. | [02] | 94901-02490 | WASHER | 22877-1100A |

| 048. | [01] | 94919-80270 | COLLAR, PRESSBOARD | |

| 048. | [01] | 94919-80270 | COLLAR, PRESSBOARD | 22843-2240A |

| 049. | [02] | 09031-70060 | PLUG, SCREW | 22845-1060A |

| 049. | [02] | 09031-70060 | PLUG, SCREW | |

| 050. | [02] | 09806-50020 | GASKET | |

| 050. | [02] | 09806-50020 | GASKET | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 055. | [01] | 94905-62390 | NUT | 22825-2570A |

| 055. | [01] | 94905-62390 | NUT | |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90051 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90051 | OVERHAUL KIT, SUPP | |

| 201. | [03] | 29400-90540 | OVERHAUL KIT, SUPP | |

| 201. | [03] | 29400-90540 | OVERHAUL KIT, SUPP | |

| 300. | [01] | 29409-05000 | ELEMENT KIT, SUPPL | |

| 300. | [01] | 29409-05000 | ELEMENT KIT, SUPPL | |

| 301. | [02] | 29409-05010 | ELEMENT KIT, SUPPL | |

| 301. | [02] | 29409-05010 | ELEMENT KIT, SUPPL |

Include in #3:

29405-00081

as PUMP ASSY, SUPPLY

29405-00081

29405-00081

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00081 | 22730-1341 | PUMP ASSY, SUPPLY |

Information:

Fuel and the Effect from Cold Weather

The two types of diesel fuel available for your truck engine are typically grades No. 1 and No. 2. Although No. 2 diesel fuel is the most commonly used fuel, No. 1 diesel fuel or a blend of No. 1 and No. 2, is the fuel that is best suited for cold weather operation.During cold weather operation, it may be necessary for you to use No. 2 diesel fuel since quantities of No. 1 diesel fuel are limited and generally are only available during the winter months and in the colder climates.There are two major differences between No. 1 and No. 2 diesel fuel. No. 1 diesel fuel has a lower cloud point and a lower pour point.The cloud point is the temperature at which a cloud or haze of wax crystals will begin to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel will begin to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel and anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather. The average No. 1 diesel fuel has a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No. 2 diesel fuel. When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency, but should not experience any other operating effects.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.The use of starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather when No. 2 diesel fuel is used.Fuel Related Components in Cold Weather

3176 Fuel Cooling

Fuel cooled ECMThe 3176 electronic control module is fuel cooled. Fuel is routed from the tank, to a primary fuel filter, through the transfer pump, then through cored passages in the electronic control module housing, on to the secondary fuel filter, and finally to the injection pump.Inlet fuel temperature to the transfer pump must never exceed 149°F (65°C). Fuel temperatures in excess of 149°F (65°C) reduce the life of the electronics and reduce engine power availability.Fuel Heaters

Fuel heaters prevent plugging of the fuel filters in cold weather due to waxing. Non-thermostatically controlled fuel heaters can heat the fuel in excess of 149°F (65°C). High fuel temperatures reduce engine performance and 3176 System reliability. The 3176 ECM does not dissipate enough heat into the fuel to prevent the use of fuel heaters.A fuel heater should be installed so that the fuel is heated before it enters the first (primary) fuel filter.Use a fuel heater that is mechanically simple, yet adequate for the application. The fuel heater should also

The two types of diesel fuel available for your truck engine are typically grades No. 1 and No. 2. Although No. 2 diesel fuel is the most commonly used fuel, No. 1 diesel fuel or a blend of No. 1 and No. 2, is the fuel that is best suited for cold weather operation.During cold weather operation, it may be necessary for you to use No. 2 diesel fuel since quantities of No. 1 diesel fuel are limited and generally are only available during the winter months and in the colder climates.There are two major differences between No. 1 and No. 2 diesel fuel. No. 1 diesel fuel has a lower cloud point and a lower pour point.The cloud point is the temperature at which a cloud or haze of wax crystals will begin to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel will begin to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel and anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather. The average No. 1 diesel fuel has a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No. 2 diesel fuel. When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency, but should not experience any other operating effects.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.The use of starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather when No. 2 diesel fuel is used.Fuel Related Components in Cold Weather

3176 Fuel Cooling

Fuel cooled ECMThe 3176 electronic control module is fuel cooled. Fuel is routed from the tank, to a primary fuel filter, through the transfer pump, then through cored passages in the electronic control module housing, on to the secondary fuel filter, and finally to the injection pump.Inlet fuel temperature to the transfer pump must never exceed 149°F (65°C). Fuel temperatures in excess of 149°F (65°C) reduce the life of the electronics and reduce engine power availability.Fuel Heaters

Fuel heaters prevent plugging of the fuel filters in cold weather due to waxing. Non-thermostatically controlled fuel heaters can heat the fuel in excess of 149°F (65°C). High fuel temperatures reduce engine performance and 3176 System reliability. The 3176 ECM does not dissipate enough heat into the fuel to prevent the use of fuel heaters.A fuel heater should be installed so that the fuel is heated before it enters the first (primary) fuel filter.Use a fuel heater that is mechanically simple, yet adequate for the application. The fuel heater should also