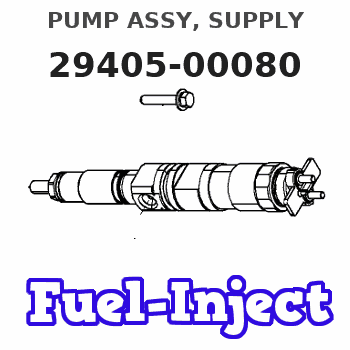

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Fuel Injection Pump 294050-0080 294050 0080 22730-1340

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

Fuel Injection Pump 294050-0080 22730-1340 for Hino Engine J08E Truck 500 Series

100% Apollo part number: 294050-0080 22730-1340 || application: for Hino Engine J08E Truck 500 Series

100% Apollo part number: 294050-0080 22730-1340 || application: for Hino Engine J08E Truck 500 Series

Diesel Fuel Injection Pump 294050-0080 294050 0080 22730-1340

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

You can express buy:

USD 399.26

01-06-2025

01-06-2025

HP4 Diesel fuel Common Rail injection pump 294050-0080 294050-0081 22730-1341 S2273-01341 16730Z503 For Hino J08E Engine

USD 525

13-05-2025

13-05-2025

Common Rail Injection Pump For Hino Motor J08E High Pressure Oil Pump 295050-0720 294050-0080 294050-0081 22730-1340 22730-1341

Images:

USD 384.18

[19-May-2025]

USD 461.01

[01-Jun-2025]

USD 19.99

[10-Nov-2022]

Components :

| 001. | PUMP ASSY, SUPPLY | 29405-00080 |

| 001. | PUMP ASSY, SUPPLY | 29405-00080 |

| 001. | PUMP ASSY, SUPPLY | 29405-00080 |

| 001. | PUMP ASSY, SUPPLY | 29405-00080 |

| 002. | OVERHAUL KIT, SUPP | 29400-90050 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00080 | 22730-1340 | PUMP ASSY, SUPPLY | |

| 22730-1341 | HINO | PUMP ASSY, SUPPLY | |

| 22730-1340 | HINO | PUMP ASSY, SUPPLY | |

| 16730Z503B | UD TRUCKS | PUMP ASSY, SUPPLY | |

| 16730Z501B | UD TRUCKS | PUMP ASSY, SUPPLY | |

| S2273-01341 | HINO | PUMP ASSY, SUPPLY |

Information:

Engine Operating Cost Summary

The Operating Cost Summary section is exactly what it implies, a summary. Here the total dollar expense and percentage of the total operating expense is calculated for each of the eight subsections listed in the Engine Operating Information section. The eight individual elements are then totaled and divided by the ownership period to yield the cost per mile (km), hour or day. Similar calculations are also made for only the maintenance and repair portion of the total operating cost.An Engine Operating Cost Analysis is a useful tool that can be used to:* Project the expected operating cost of a Caterpillar truck engine.* Identify the impact of individual elements on engine operating costs.* Determine expected operating costs if Caterpillar service and overhaul recommendations are followed.* Determine the cost per mile (km) or hour figures that you can obtain by having your dealer perform various levels of preventive maintenance as recommended by Caterpillar.* Determine the savings to be realized if Caterpillar repair kits, exchange components, etc., are used by those of you who elect to perform your own maintenance.* Determine the proper way to realize full value of your Caterpillar Engine by utilizing genuine Caterpillar parts and following Caterpillar recommended guidelines for preventive maintenance and before failure repairs.In conclusion, an Engine Operating Cost Analysis is a tool that was designed to identify costly problem areas for the purpose of helping you reduce your operating costs.

The Operating Cost Summary section is exactly what it implies, a summary. Here the total dollar expense and percentage of the total operating expense is calculated for each of the eight subsections listed in the Engine Operating Information section. The eight individual elements are then totaled and divided by the ownership period to yield the cost per mile (km), hour or day. Similar calculations are also made for only the maintenance and repair portion of the total operating cost.An Engine Operating Cost Analysis is a useful tool that can be used to:* Project the expected operating cost of a Caterpillar truck engine.* Identify the impact of individual elements on engine operating costs.* Determine expected operating costs if Caterpillar service and overhaul recommendations are followed.* Determine the cost per mile (km) or hour figures that you can obtain by having your dealer perform various levels of preventive maintenance as recommended by Caterpillar.* Determine the savings to be realized if Caterpillar repair kits, exchange components, etc., are used by those of you who elect to perform your own maintenance.* Determine the proper way to realize full value of your Caterpillar Engine by utilizing genuine Caterpillar parts and following Caterpillar recommended guidelines for preventive maintenance and before failure repairs.In conclusion, an Engine Operating Cost Analysis is a tool that was designed to identify costly problem areas for the purpose of helping you reduce your operating costs.