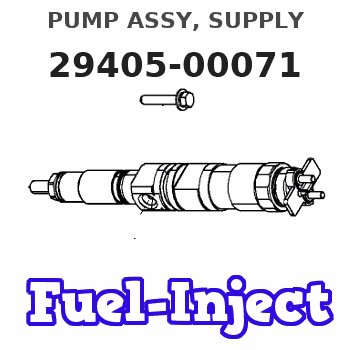

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

16730Z600A Fuel Pump Case Fuel Injection Pump Hp4 294050-0071 16730Z600A Fuel Pump

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

HP4 Diesel Fuel Common Rail Injection Pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 Compatible For NISSAN TRUCK

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

Fuel injection pump Fits for Nissan MD92 engine Truck 294050-0071 2940500071

KoovDem Part Number: 294050-0071 2940500071 || Product Name: 294050-0071 2940500071 Fuel injection pump || This product is designed for Nissan MD92 engine trucks, providing maximum performance and durability for heavy-duty vehicles. It ensures reliable operation in demanding conditions, with precise fit and high-quality construction. Upgrade or replace worn-out parts to improve efficiency and longevity of your truck fleet. A reliable choice to keep your Nissan MD92 engine truck running smoothly for years. || 1 unit of Fuel Injection Pump || . Our team will assist you in verifying the compatibility of the part with your engine. It is essential to ensure that you are purchasing the correct product to avoid any issues during installation or operation. Feel free to reach out to us for any assistance or clarification regarding the product or its compatibility with your engine. Your satisfaction is our priority. Thank you for your cooperation.

KoovDem Part Number: 294050-0071 2940500071 || Product Name: 294050-0071 2940500071 Fuel injection pump || This product is designed for Nissan MD92 engine trucks, providing maximum performance and durability for heavy-duty vehicles. It ensures reliable operation in demanding conditions, with precise fit and high-quality construction. Upgrade or replace worn-out parts to improve efficiency and longevity of your truck fleet. A reliable choice to keep your Nissan MD92 engine truck running smoothly for years. || 1 unit of Fuel Injection Pump || . Our team will assist you in verifying the compatibility of the part with your engine. It is essential to ensure that you are purchasing the correct product to avoid any issues during installation or operation. Feel free to reach out to us for any assistance or clarification regarding the product or its compatibility with your engine. Your satisfaction is our priority. Thank you for your cooperation.

You can express buy:

USD 436.28

19-05-2025

19-05-2025

Common rail fuel pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 for NISSAN TRUCK MD92

USD 420.08

19-05-2025

19-05-2025

Common rail fuel pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 for NISSAN TRUCK MD92

Images:

USD 990.25

[19-May-2025]

USD 399.98

[29-May-2025]

USD 383.35

[15-May-2025]

USD 461.01

[26-May-2025]

Scheme ###:

| 000. | [01] | 29405-00070 | PUMP ASSY, SUPPLY | 16730Z6005 |

| 000. | [01] | 29405-00071 | PUMP ASSY, SUPPLY | 16730Z600A |

| 001. | [01] | 29410-05072 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15010 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 005. | [01] | 29417-05000 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05010 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05030 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90110 | BOLT, SOCKET | |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35030 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45010 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [05] | 09644-90050 | BOLT, SOCKET | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 021. | [03] | 29414-00110 | VALVE SUB-ASSY, SU | |

| 022. | [03] | 29419-80020 | O-RING, SUPPLY PUM | |

| 023. | [03] | 29413-50011 | PLUG, CYLINDER | |

| 028. | [01] | 29409-00220 | ELEMENT KIT, SUPPL | |

| 029. | [01] | 29409-00260 | ELEMENT KIT, SUPPL | |

| 030. | [01] | 29409-00250 | ELEMENT KIT, SUPPL | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00020 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00570 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00670 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50010 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05030 | PIPE, SUPPLY PUMP | |

| 036. | [02] | 29401-05060 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 041. | [01] | 09543-80170 | SCREW, HOLLOW | |

| 041. | [01] | 09543-80010 | SCREW, HOLLOW | |

| 042. | [02] | 94901-02530 | WASHER | |

| 043. | [01] | 94919-80260 | COLLAR, PRESSBOARD | |

| 044. | [01] | 94918-00310 | SCREW, HOLLOW | 16753Z6002 |

| 045. | [02] | 94901-02490 | WASHER | |

| 046. | [01] | 94919-80270 | COLLAR, PRESSBOARD | |

| 047. | [02] | 09031-70060 | PLUG, SCREW | |

| 048. | [02] | 09806-50020 | GASKET | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90020 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90051 | OVERHAUL KIT, SUPP | |

| 201. | [03] | 29400-90540 | OVERHAUL KIT, SUPP | |

| 300. | [02] | 29409-05010 | ELEMENT KIT, SUPPL | |

| 301. | [01] | 29409-05020 | ELEMENT KIT, SUPPL |

Include in #3:

29405-00070

as PUMP ASSY, SUPPLY

29405-00071

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00071 | PUMP ASSY, SUPPLY |

Information:

Articulated Truck735B (S/N: T4P1-UP)740B (S/N: T4R1-UP)Asphalt CompactorCB44B (S/N: JXL1-UP; NSL1-UP)CD44B (S/N: JXE1-UP)CD54B (S/N: GRT1-UP; J9T1-UP)Backhoe Loader415F2 (S/N: HWA1-UP)427F2 (S/N: HWK1-UP)Ejector Truck740B EJECTOR (S/N: T4S1-UP)Engine (Captive)C13 (S/N: TXM1-UP; M4X1-UP)Excavator311F (S/N: LZF1-UP; JFT1-UP; KCW1-UP)312F (S/N: FKE1-UP)313F (S/N: GJD1-UP; HDK1-UP)336E (S/N: RZA1-UP; KED1-UP; YCE1-UP; TEG1-UP; FJH1-UP; GTJ1-UP; JRJ1-UP; SSL1-UP; YEP1-UP; CMR1-UP; HDW1-UP; BZY1-UP; TMZ1-UP)349E (S/N: FJB1-UP; DGE1-UP; SPG1-UP; TFG1-UP; RGH1-UP; KCN1-UP; MZW1-UP; KFX1-UP; MPZ1-UP; WHZ1-UP)Forest Machine568 (S/N: BRB1-UP; YJX1-UP)Generator SetC13GENSET (S/N: X3M1-UP)C15 GEN SET (S/N: T4A1-UP; X5M1-UP)Industrial Engine3.4B (S/N: CJ31-UP)C13 (S/N: KWJ1-UP)C15 (S/N: LDN1-UP)C18 (S/N: BDN1-UP)C2.2 (S/N: G9P1-UP)C3.4B (S/N: CJG1-UP)C9.3 (S/N: C9N1-UP; D9N1-UP)Motor Grader12M Series 2 (S/N: F9B1-UP; F9M1-UP; R9P1-UP; R9S1-UP)140M Series 2 (S/N: M9D1-UP; R9G1-UP; M9J1-UP; R9M1-UP)160M Series 2 (S/N: M9E1-UP; M9K1-UP; R9L1-UP; R9T1-UP)Petroleum EngineC13 PETROLEUM (S/N: A5Z1-UP)Pneumatic CompactorCW14 (S/N: LTJ1-UP)Track-Type TractorD6T (S/N: KSB1-UP; ZJB1-UP; JZC1-UP; DTD1-UP; EJJ1-UP; SLJ1-UP; GMK1-UP; RRK1-UP; TSM1-UP; WLM1-UP; PLR1-UP; JRW1-UP; RCW1-UP)D7E (S/N: TJA1-UP; TAN1-UP)D8T (S/N: MLN1-UP; FCT1-UP)Wheel Loader966K (S/N: PBG1-UP; TFS1-UP)966K Series XE (S/N: NGX1-UP)972K (S/N: PEM1-UP; Z4W1-UP)980K (S/N: W7K1-UP; GTZ1-UP)Wheel Tractor Scraper621H (S/N: DBK1-UP; HKK1-UP)623H (S/N: DBF1-UP)627H (S/N: DBW1-UP)Introduction

There are three approved processes for performing the required Diesel Particulate Filter (DPF) maintenance on products equipped with a DPF.Do not perform any procedure in this Special Instruction until you have read this entire Special Instruction and you understand this information. Caterpillar does not recommend any equipment or process for cleaning the DPF other than the procedures listed in this Special Instruction.Note: The approved Caterpillar DPF maintenance procedure permits any of the following actions be taken when the DPF needs to be cleaned:

Replacement of the existing DPF with a new Caterpillar DPF

Replacement of the existing DPF with a remanufactured Caterpillar DPF

Replacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device.The DPF can be cleaned a maximum of three times or 20,000 total DPF hours.Replacement with a New or a Remanufactured Caterpillar Diesel Particulate Filter (DPF)

Refer to Table 3 for the existing part number of the filter assembly being serviced along with the corresponding new and remanufactured service kits.

Table 1

Filter Assembly Part Number New Service Kit Part Number Reman Service Kit Part Number - Upgrade to New Reman Service Kit Part Number - Cat Factory Cleaned Part Number of Included Clamp

358-3658 358-3659 20R-0696 20R-5620 345-1858

358-3661 358-3662 20R-0697 20R-5621 345-1849

358-3663 358-3664 20R-0698 20R-5622 345-1849

358-3666 358-3667 20R-0699 20R-5623 345-1839

358-3668 358-3669 20R-0700 20R-5624 345-1839 Refer to Reman Core Acceptance Criteria, SELD0292 for further information.When replacing the existing DPF with either a new or remanufactured DPF, perform the following:

Perform a "Manual DPF Regeneration"

Mark the DPF as shown below in Step 4

Perform the "DPF Ash Service" listed below.Replacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device

Inorder to maintain emissions documentationit is necessary that only the same part number DPF must be reinstalled. The cleaned DPF must have a remaining service life similar to the DPF being replaced.Inspect the DPF for markings of a previous cleaning. Refer to Illustration 1 for a typical example of cleaning markings.Cleaning the DPF

Follow this cleaning procedure for removal of the ash from a DPF.

There are three approved processes for performing the required Diesel Particulate Filter (DPF) maintenance on products equipped with a DPF.Do not perform any procedure in this Special Instruction until you have read this entire Special Instruction and you understand this information. Caterpillar does not recommend any equipment or process for cleaning the DPF other than the procedures listed in this Special Instruction.Note: The approved Caterpillar DPF maintenance procedure permits any of the following actions be taken when the DPF needs to be cleaned:

Replacement of the existing DPF with a new Caterpillar DPF

Replacement of the existing DPF with a remanufactured Caterpillar DPF

Replacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device.The DPF can be cleaned a maximum of three times or 20,000 total DPF hours.Replacement with a New or a Remanufactured Caterpillar Diesel Particulate Filter (DPF)

Refer to Table 3 for the existing part number of the filter assembly being serviced along with the corresponding new and remanufactured service kits.

Table 1

Filter Assembly Part Number New Service Kit Part Number Reman Service Kit Part Number - Upgrade to New Reman Service Kit Part Number - Cat Factory Cleaned Part Number of Included Clamp

358-3658 358-3659 20R-0696 20R-5620 345-1858

358-3661 358-3662 20R-0697 20R-5621 345-1849

358-3663 358-3664 20R-0698 20R-5622 345-1849

358-3666 358-3667 20R-0699 20R-5623 345-1839

358-3668 358-3669 20R-0700 20R-5624 345-1839 Refer to Reman Core Acceptance Criteria, SELD0292 for further information.When replacing the existing DPF with either a new or remanufactured DPF, perform the following:

Perform a "Manual DPF Regeneration"

Mark the DPF as shown below in Step 4

Perform the "DPF Ash Service" listed below.Replacement of the existing DPF with a similar DPF cleaned by a Caterpillar approved cleaning device

Inorder to maintain emissions documentationit is necessary that only the same part number DPF must be reinstalled. The cleaned DPF must have a remaining service life similar to the DPF being replaced.Inspect the DPF for markings of a previous cleaning. Refer to Illustration 1 for a typical example of cleaning markings.Cleaning the DPF

Follow this cleaning procedure for removal of the ash from a DPF.