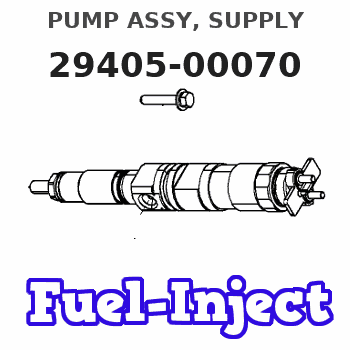

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

HP4 Diesel Fuel Common Rail Injection Pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 Compatible For NISSAN TRUCK

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

HP4 Diesel Fuel Common Rail Injection Pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 Compatible For NISSAN TRUCK

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

DYQSBAZD Plug-and-play design perfectly matches the interface of vehicle fuel system, and the installation process is simple without complicated modification. || Advanced electronic control technology can accurately control fuel injection according to the real-time working conditions of the engine and effectively improve fuel economy. || Provide strong and stable fuel pressure, ensure the fuel to enter the combustion chamber quickly and fully, and significantly enhance the power and torque of the engine. || The unique design enables it to accurately supply the right amount of fuel in low temperature environment, effectively solving the problem of difficult starting of vehicles in cold weather. || The key components are made of high-quality materials, which have excellent wear resistance and corrosion resistance after special process treatment, effectively reducing the wear of components.

HP4 Diesel Fuel Common Rail Injection Pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 Compatible For NISSAN TRUCK

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || HP4 Diesel Fuel Common Rail Injection Pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 Compatible For NISSAN TRUCK

TWXLLDRM This fuel injection pump uses cutting-edge injection technology to realize ultra-fine atomization of fuel, greatly improving combustion efficiency, enabling the engine to release more powerful power and significantly improving response speed. || We insist on using aviation-grade high-strength materials, which have excellent high temperature resistance, high pressure resistance and wear resistance. From raw materials to many fine processes on the production line, every step exceeds the quality standards. || Our fuel injection pump provides accurate adaptation models, and in-depth research and development and testing are carried out for the matched models to ensure that the products can perfectly fit your car in terms of interfaces, dimensions, operating parameters and so on. || This fuel injection pump can accurately control the fuel injection quantity, whether on urban roads or at high speed, it can ensure that the engine can get accurate and appropriate fuel, effectively improve fuel utilization and reduce fuel consumption. || HP4 Diesel Fuel Common Rail Injection Pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 Compatible For NISSAN TRUCK

You can express buy:

USD 436.28

19-05-2025

19-05-2025

Common rail fuel pump 16730-Z6005 16730-Z600A 294050-0070 294050-0071 294050-0074 for NISSAN TRUCK MD92

Images:

USD 990.25

[19-May-2025]

USD 399.98

[29-May-2025]

USD 384.18

[19-May-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29405-00070 |

| 001. | PUMP ASSY, SUPPLY | 29405-00070 |

| 001. | PUMP ASSY, SUPPLY | 29405-00070 |

| 001. | PUMP ASSY, SUPPLY | 29405-00070 |

| 001. | PUMP ASSY, SUPPLY | 29405-00070 |

| 001. | PUMP ASSY, SUPPLY | 29405-00070 |

| 002. | OVERHAUL KIT, SUPP | 29400-90050 |

| 002. | OVERHAUL KIT, SUPP | 29400-90051 |

Scheme ###:

| 000. | [01] | 29405-00071 | PUMP ASSY, SUPPLY | |

| 001. | [01] | 29410-05071 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15010 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05000 | RING SUB-ASSY, CAM | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05030 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05010 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90110 | BOLT, SOCKET | ME736324 |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35030 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45010 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [05] | 09644-90050 | BOLT, SOCKET | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 021. | [03] | 29414-00110 | VALVE SUB-ASSY, SU | |

| 022. | [03] | 29419-80020 | O-RING, SUPPLY PUM | |

| 023. | [03] | 29413-50011 | PLUG, CYLINDER | |

| 028. | [01] | 29409-00220 | ELEMENT KIT, SUPPL | |

| 029. | [01] | 29409-00260 | ELEMENT KIT, SUPPL | |

| 030. | [01] | 29409-00250 | ELEMENT KIT, SUPPL | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00020 | SENSOR, FUEL TEMPE | MK387519 |

| 033. | [01] | 29420-00570 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00670 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50010 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05030 | PIPE, SUPPLY PUMP | |

| 036. | [02] | 29401-05060 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 041. | [01] | 09543-80170 | SCREW, HOLLOW | ME743860 |

| 041. | [01] | 09543-80010 | SCREW, HOLLOW | |

| 042. | [02] | 94901-02530 | WASHER | ME743814 |

| 043. | [01] | 94919-80260 | COLLAR, PRESSBOARD | ME702848 |

| 044. | [01] | 94918-00310 | SCREW, HOLLOW | ME702236 |

| 045. | [02] | 94901-02490 | WASHER | ME743859 |

| 046. | [01] | 94919-80270 | COLLAR, PRESSBOARD | ME702632 |

| 047. | [02] | 09031-70060 | PLUG, SCREW | ME702176 |

| 048. | [02] | 09806-50020 | GASKET | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90020 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90051 | OVERHAUL KIT, SUPP | |

| 201. | [03] | 29400-90540 | OVERHAUL KIT, SUPP | |

| 300. | [02] | 29409-05010 | ELEMENT KIT, SUPPL | |

| 301. | [01] | 29409-05020 | ELEMENT KIT, SUPPL |

Include in #3:

29405-00071

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00070 | 16730Z6005 | PUMP ASSY, SUPPLY | |

| 16730Z600A | UD TRUCKS | PUMP ASSY, SUPPLY | |

| 16730Z6005 | UD TRUCKS | PUMP ASSY SUPPLY |

Information:

Start By:a. remove oil pump1. Check the main bearing caps for identification for their location and direction in the block. The caps must be installed in the same location and direction from which they were removed. 2. Remove number 2 through number 6 bearing caps (1). Remove thrust plates from the number 4 main bearing.

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either the crankshaft or cylinder block or both.

3. Remove the upper halves of the main bearings by putting Tool (A) in oil hole (2) in the crankshaft. Turn the crankshaft in the direction which will push the end of the bearing with a tab out first.4. Remove the lower halves of the bearings from the caps. Install the bearings dry when the clearance checks are made. Put clean engine oil on the bearings for final assembly.5. Install the new bearings in the caps.6. Install the upper halves of the bearings in the cylinder with Tool (A).

Be sure tabs (3) on the back of the bearings fit in the tab slots of the caps and cylinder block. The serviceman must be very careful to use Plastigage, Tool (B) correctly. The following points must be remembered.

Make sure that the backs of the bearings and the bores are clean and dry.Make sure that the bearing locking tabs are properly seated in their slots.The crankshaft must be free of oil where the Plastigage touches it.If the main bearing clearances are checked with the engine upright or on its side, the crankshaft must be supported. Use a jack under an adjacent crankshaft counterweight and hold the crankshaft against the crown of the bearing. If the crankshaft is not supported, the weight of the crankshaft will cause incorrect readings.Put a piece of Plastigage on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.Do not turn the crankshaft with the Plastigage installed.Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.Remove the Plastigage before reinstalling the cap.When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004 in) the readings may be low by 0.013 to 0.025 mm (.0005 to .0010 in). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider that the

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either the crankshaft or cylinder block or both.

3. Remove the upper halves of the main bearings by putting Tool (A) in oil hole (2) in the crankshaft. Turn the crankshaft in the direction which will push the end of the bearing with a tab out first.4. Remove the lower halves of the bearings from the caps. Install the bearings dry when the clearance checks are made. Put clean engine oil on the bearings for final assembly.5. Install the new bearings in the caps.6. Install the upper halves of the bearings in the cylinder with Tool (A).

Be sure tabs (3) on the back of the bearings fit in the tab slots of the caps and cylinder block. The serviceman must be very careful to use Plastigage, Tool (B) correctly. The following points must be remembered.

Make sure that the backs of the bearings and the bores are clean and dry.Make sure that the bearing locking tabs are properly seated in their slots.The crankshaft must be free of oil where the Plastigage touches it.If the main bearing clearances are checked with the engine upright or on its side, the crankshaft must be supported. Use a jack under an adjacent crankshaft counterweight and hold the crankshaft against the crown of the bearing. If the crankshaft is not supported, the weight of the crankshaft will cause incorrect readings.Put a piece of Plastigage on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.Do not turn the crankshaft with the Plastigage installed.Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.Remove the Plastigage before reinstalling the cap.When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004 in) the readings may be low by 0.013 to 0.025 mm (.0005 to .0010 in). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider that the