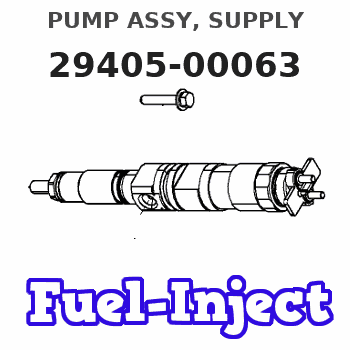

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Fuel Injection Pump RE546126 294050-0064 294050-0065 SE501922 RE534156 294050-0063

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

294050-0062 Diesel Engine Parts Pressure Fuel Injection Pump RE546126 RE534156 294050-0062

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

294050-0060 294050-0061 294050-0062 RE519597 RE534156 Fuel Injection Pump for John Deere 6090 9.0L Engine S450 Tractor 1270D 1710D 1711D Harvester

HIRINTOL 🔸Replace Part Number: 294050-0060, 294050-0061, 294050-0062, RE519597, RE534156 || 🔸Engine Model: for John Deere Engine 6090, 6090HTJ02, 6090HTJ01; for Isuzu 6HK1 Engine || 🔸Compatible Model: for John Deere Harvester 1270D, 1710D, 1711D; for John Deere Tractor S450 || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions.

HIRINTOL 🔸Replace Part Number: 294050-0060, 294050-0061, 294050-0062, RE519597, RE534156 || 🔸Engine Model: for John Deere Engine 6090, 6090HTJ02, 6090HTJ01; for Isuzu 6HK1 Engine || 🔸Compatible Model: for John Deere Harvester 1270D, 1710D, 1711D; for John Deere Tractor S450 || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions.

You can express buy:

USD 392.84

14-06-2025

14-06-2025

diesel fuel injection pump RE546126 294050-0064 294050-0065 SE501922 RE534156 294050-0063

USD 457.71

14-05-2025

14-05-2025

High pressure injector fuel pump 294050-0060 294050-0063 diesel fuel injection pump common rail pump

Images:

USD 520

[19-May-2025]

USD 391.72

[14-Jun-2025]

USD 765.04

[01-Jul-2023]

Scheme ###:

| 000. | [01] | 29405-00062 | PUMP ASSY, SUPPLY | RE519597 |

| 000. | [01] | 29405-00062 | PUMP ASSY, SUPPLY | RE534156 |

| 000. | [01] | 29405-00063 | PUMP ASSY, SUPPLY | RE534156 |

| 000. | [01] | 29405-00064 | PUMP ASSY, SUPPLY | RE546126 |

| 001. | [01] | 29410-05090 | HOUSING SUB-ASSY, | |

| 001. | [01] | 29410-05310 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15080 | CAMSHAFT, SUPPLY P | |

| 003. | [01] | 29419-15000 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 004. | [01] | 29402-10040 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05000 | RING SUB-ASSY, CAM | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05070 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05030 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05010 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [08] | 09644-90110 | BOLT, SOCKET | |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35020 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45040 | COVER, FEED PUMP | |

| 011. | [01] | 29418-45000 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [03] | 09644-90050 | BOLT, SOCKET | |

| 015. | [01] | 29409-00230 | ELEMENT KIT, SUPPL | |

| 015. | [01] | 29409-00710 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00250 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00630 | ELEMENT KIT, SUPPL | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 021. | [01] | 29409-00240 | ELEMENT KIT, SUPPL | |

| 021. | [01] | 29409-00620 | ELEMENT KIT, SUPPL | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00020 | SENSOR, FUEL TEMPE | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00380 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00180 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00130 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60030 | O-RING, VALVE | |

| 034. | [01] | 29428-50040 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00200 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05020 | PIPE, SUPPLY PUMP | |

| 036. | [02] | 29401-05100 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 041. | [01] | 29425-90020 | GASKET, SOLENOID | |

| 042. | [02] | 09031-70060 | PLUG, SCREW | |

| 043. | [02] | 09806-50020 | GASKET | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 053. | [01] | 09003-45220 | PLUG | |

| 054. | [01] | 09003-45230 | PLUG | |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | RE524528 |

| 102. | [01] | 29400-90020 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90051 | OVERHAUL KIT, SUPP |

Include in #3:

29405-00063

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00063 | RE534156 | PUMP ASSY, SUPPLY |

Information:

Walk-Around Inspection

Inspect Engine for Leaks and Loose Connections

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before performing maintenance to keep dirt and debris from entering engine components. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps. * Inspect the fan and accessory drive belts for cracks, breaks or other damage.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a 2 or 3 belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers. * Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. * Inspect wiring for loose connections and worn or frayed wires. * Inspect air intake system hoses and elbows for cracks and loose clamps. * Inspect ECM to cylinder head ground strap for good connection and condition.* Inspect engine-to-frame ground strap for good connection and condition.* All guards must be in place. Repair or replace missing or damaged guards.Engine Crankcase

Check Oil Level

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the crankcase lube oil system.

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to Calibrating the oil level gauge in the Dipstick section of this manual or consult your Caterpillar dealer before changing oil and operating the engine. 3. Remove

Inspect Engine for Leaks and Loose Connections

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before performing maintenance to keep dirt and debris from entering engine components. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses for cracks and loose clamps. * Inspect the fan and accessory drive belts for cracks, breaks or other damage.Belts for multiple groove pulleys must be replaced as matched sets. If only one belt of a 2 or 3 belt set is replaced, it will carry more of a load than the belts not replaced since the older belts are stretched. The additional load on the new belt could cause it to break. * Inspect the water pump for leaks. * Inspect the engine for oil leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers. * Inspect the fuel system for leaks, loose fuel line clamps and fittings and loose or worn hoses. * Inspect wiring for loose connections and worn or frayed wires. * Inspect air intake system hoses and elbows for cracks and loose clamps. * Inspect ECM to cylinder head ground strap for good connection and condition.* Inspect engine-to-frame ground strap for good connection and condition.* All guards must be in place. Repair or replace missing or damaged guards.Engine Crankcase

Check Oil Level

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the crankcase lube oil system.

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to Calibrating the oil level gauge in the Dipstick section of this manual or consult your Caterpillar dealer before changing oil and operating the engine. 3. Remove