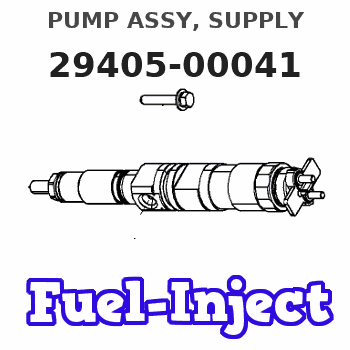

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Compatible with Mitsubishi Fuso 6M60 6M60T SK350-8 SK330-8 Excavator HP4 Fuel Injector Pump JO8E VH22100E0020 22100-E0020 294050-0041 294050-0042 294050-0043 294050-0044

EWAIDI Part Number:294050-0043 294050-0041 294050-0042 294050-0044 2940500043 2940500041 2940500042 2940500044 || Application:For Mitsubishi 6M60T For SK350-8 SK330-8 Excavator JO8E VH22100E0020 22100-E0020 || The fuel injector pump is a vital part of a vehicle's fuel system, delivering fuel to engine cylinders for optimal combustion and performance. Operating at high pressure and precision, it controls fuel flow using pistons and valves. Malfunctions can cause poor efficiency, misfires, and reduced performance, making regular maintenance crucial for smooth operation and longevity. || Attention - The application information displayed is intended for informational purposes only. It is highly recommended that you verify the part number and conduct a thorough comparison with your old parts before proceeding with the purchase. Should you have any inquiries or concerns, please do not hesitate to reach out to us. || Good Value Option-This item offers consistent performance, reliable functionality, simple installation, and quick responsiveness.

EWAIDI Part Number:294050-0043 294050-0041 294050-0042 294050-0044 2940500043 2940500041 2940500042 2940500044 || Application:For Mitsubishi 6M60T For SK350-8 SK330-8 Excavator JO8E VH22100E0020 22100-E0020 || The fuel injector pump is a vital part of a vehicle's fuel system, delivering fuel to engine cylinders for optimal combustion and performance. Operating at high pressure and precision, it controls fuel flow using pistons and valves. Malfunctions can cause poor efficiency, misfires, and reduced performance, making regular maintenance crucial for smooth operation and longevity. || Attention - The application information displayed is intended for informational purposes only. It is highly recommended that you verify the part number and conduct a thorough comparison with your old parts before proceeding with the purchase. Should you have any inquiries or concerns, please do not hesitate to reach out to us. || Good Value Option-This item offers consistent performance, reliable functionality, simple installation, and quick responsiveness.

Fuel injection Pump 294050-0042 ME302144 for Mitsubishi Engine 6M60 6M60T

FGNTWP Part Number:ME604302, ME302144, ME306386, ME307482, 294050-0040, 294050-0041, 294050-0042, 294050-0043, 2940500040, 2940500041, 2940500042, 2940500043, ME304302 || Application:Fit for Mitsubishi Truck: Fuso

FGNTWP Part Number:ME604302, ME302144, ME306386, ME307482, 294050-0040, 294050-0041, 294050-0042, 294050-0043, 2940500040, 2940500041, 2940500042, 2940500043, ME304302 || Application:Fit for Mitsubishi Truck: Fuso

294050-0041 294050-0042 294050-0044 ME302144 ME307482 Fuel Injection Pump for Mitsubishi Fuso 6M60 6M60T 7.5L Fighter Truck

HIRINTOL 🔸Replace Part Number: 294050-0041, 294050-0042, 294050-0043, 294050-0044, ME302144, ME307482 || 🔸Compatible Model: for Mitsubishi Fuso 6M60 6M60T 7.5L Fighter Truck. || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

HIRINTOL 🔸Replace Part Number: 294050-0041, 294050-0042, 294050-0043, 294050-0044, ME302144, ME307482 || 🔸Compatible Model: for Mitsubishi Fuso 6M60 6M60T 7.5L Fighter Truck. || 🔸Efficient And Stable: Using advanced technology, it can provide efficient and stable fuel supply to ensure the normal operation of the vehicle. || 🔸Durable And Reliable: Tested and proven many times, it has a long life and reliable quality to keep working under extreme conditions. || 🔸Easy Installation: standard interface design, easy installation, plug and play, no professional skills required.

You can express buy:

USD 418.16

14-06-2025

14-06-2025

HP4 Diesel Fuel Injection Injector pump 294050-0041 294050-0042 294050-0043 294050-0044 294050-0040 for MITSUBISHI 6M60T

USD 569.05

19-05-2025

19-05-2025

HP4 Diesel Fuel Pump High Pressure Common Rail Pump For MITSUBISHI 6M60T 6M60 294050-0041 294050-0042 ME304303 ME306386 ME302144

Images:

USD 426.22

[19-May-2025]

USD 687.24

[19-May-2025]

USD 360.15

[13-May-2025]

USD 792.64

[14-Jun-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29405-00041 |

| 001. | PUMP ASSY, SUPPLY | 29405-00041 |

| 001. | PUMP ASSY, SUPPLY | 29405-00041 |

| 001. | PUMP ASSY, SUPPLY | 29405-00041 |

| 002. | OVERHAUL KIT, SUPP | 29400-90050 |

| 003. | OVERHAUL KIT, SUPP | 29400-90840 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00041 | ME302144 | PUMP ASSY, SUPPLY |

Information:

When it is necessary to remove a component on an angle, remember that the capacity of an eyebolt is less as the angle between the supporting members and the object becomes less than 90°. Eyebolts and brackets should never be bent and should only be loaded in tension.

Use a hoist to remove heavy components. Lift the engine by using an adjustable lifting beam. All supporting members (chains and cables) should be parallel to each other, and as near perpendicular as possible to the top of the object being lifted.Some removals require the use of lifting fixtures to obtain proper balance and to provide safe handling. To remove the engine, use the two lifting eyes on the engine.Lifting eyes are designed for the arrangement as sold. Alterations to lifting eyes and/or arrangement weight make the lifting devices obsolete.If you make alterations, you are responsible for providing adequate lifting devices.Engine Storage

If the engine is not started for several weeks, the lubricating oil will drain from the cylinder walls and piston rings. Rust can form on the cylinder liner surface, which will increase engine wear and result in shorter engine life.To prevent excessive engine wear:

Be sure all lubrication recommendations mentioned in the Maintenance Management Schedule intervals chart are completed.If freezing temperatures can be expected, check the cooling system for adequate protection against freezing. A 50/50 solution of Caterpillar permanent-type antifreeze and approved water will give protection below -20°F (-29°C).If it will be impossible to start the engine every week, consult your Caterpillar dealer for instructions to prepare your engine for longer storage periods.If an engine remains out of service and its use is not immediately planned, special precautions should be taken.Refer to "Storage Procedures For Caterpillar Products," Form SEHS9031 for more detailed information on engine storage.