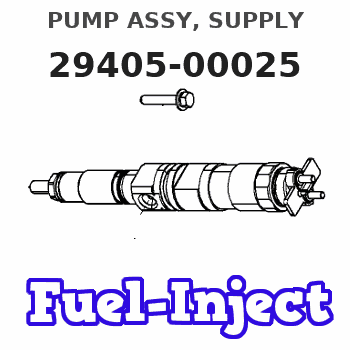

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

High Pressure Fuel Injection Pump,Compatible For ISUZU 6H04 294050-0021 294050-0022 294050-0023 294050-0024 2940500025 8-976020499

KAISUPJX Compatible For ISUZU 6H04 294050-0021 294050-0022 294050-0023 294050-0024 2940500025 8-976020499 || Stable fuel pressure output to maintain smooth engine operation. || It has good wear resistance, long service life and reduced replacement cost. || Improve the power output of the engine, so that the vehicle can have a strong power performance in a variety of conditions, whether accelerating, climbing or heavy loading, can easily cope with. || Accurate fuel injection: to achieve accurate control of fuel injection amount and injection time, every drop of fuel can be injected into the combustion chamber at the most appropriate amount, thereby improving combustion efficiency and reducing fuel consumption.

KAISUPJX Compatible For ISUZU 6H04 294050-0021 294050-0022 294050-0023 294050-0024 2940500025 8-976020499 || Stable fuel pressure output to maintain smooth engine operation. || It has good wear resistance, long service life and reduced replacement cost. || Improve the power output of the engine, so that the vehicle can have a strong power performance in a variety of conditions, whether accelerating, climbing or heavy loading, can easily cope with. || Accurate fuel injection: to achieve accurate control of fuel injection amount and injection time, every drop of fuel can be injected into the combustion chamber at the most appropriate amount, thereby improving combustion efficiency and reducing fuel consumption.

Compatible For HP4 Diesel Injection Fuel Pump 294050-0021 294050-0022 294050-0023 294050-0024 294050-0025 Compatible For ISUZU 6H04

CFNCFJGJ [Part number] : 294050-0021 294050-0022 294050-0023 294050-0024 294050-0025 || [Easy installation] : Standard interface, easy installation, plug and play, no professional skills, easy installation. || [Durable and reliable] : After multiple tests, long life, excellent quality, and stable work in extreme environments. || [Efficient and stable] : With the support of advanced technology, fuel supply is efficient and stable, ensuring the smooth flow of vehicles. || [High quality] : The use of high-quality materials and smart design, strict testing and verification, to ensure long-term stability and high reliability.

CFNCFJGJ [Part number] : 294050-0021 294050-0022 294050-0023 294050-0024 294050-0025 || [Easy installation] : Standard interface, easy installation, plug and play, no professional skills, easy installation. || [Durable and reliable] : After multiple tests, long life, excellent quality, and stable work in extreme environments. || [Efficient and stable] : With the support of advanced technology, fuel supply is efficient and stable, ensuring the smooth flow of vehicles. || [High quality] : The use of high-quality materials and smart design, strict testing and verification, to ensure long-term stability and high reliability.

CR HP4 Fuel Injection Pump Compatible with Isuzu 6H04 6HK1 Engine GMC 7.8L Duramax Medium Heavy Duty C7500 C8500 294050-0024 294050-0025 8-97602049-4 8-97602049-5

KoovDem Part Number: 294050-0024 294050-0025 8-97602049-4 8-97602049-5 || Vehicle Application:For GMC 7.8L Duramax Engine, Medium Heavy Duty C7500 C8500 || Engine Model: designed for use with Isuzu 6H04 and 6HK1 engines. This high-quality engine model is specifically built to provide optimal performance and durability for Isuzu vehicles. With precision engineering and quality craftsmanship, this engine model ensures reliable and efficient operation for your Isuzu vehicle. Upgrade your vehicle's performance with this top-notch engine model designed to meet the demands of Isuzu 6H04 and 6HK1 engines. || Warm reminder: kindly verify your part numbers before proceeding with your purchase. In case of any uncertainty, feel free to provide us with your engine model or pump part number for assistance. || Service: We offer a 5-month warranty on all products, along with 24-hour customer support for any inquiries or issues. If you have any questions regarding the product, please don't hesitate to reach out to us via email.

KoovDem Part Number: 294050-0024 294050-0025 8-97602049-4 8-97602049-5 || Vehicle Application:For GMC 7.8L Duramax Engine, Medium Heavy Duty C7500 C8500 || Engine Model: designed for use with Isuzu 6H04 and 6HK1 engines. This high-quality engine model is specifically built to provide optimal performance and durability for Isuzu vehicles. With precision engineering and quality craftsmanship, this engine model ensures reliable and efficient operation for your Isuzu vehicle. Upgrade your vehicle's performance with this top-notch engine model designed to meet the demands of Isuzu 6H04 and 6HK1 engines. || Warm reminder: kindly verify your part numbers before proceeding with your purchase. In case of any uncertainty, feel free to provide us with your engine model or pump part number for assistance. || Service: We offer a 5-month warranty on all products, along with 24-hour customer support for any inquiries or issues. If you have any questions regarding the product, please don't hesitate to reach out to us via email.

You can express buy:

USD 420.78

19-05-2025

19-05-2025

HP4 diesel injection fuel pump 294050-0021 294050-0022 294050-0023 294050-0024 294050-0025 For ISUZU 6H04

USD 517.75

13-05-2025

13-05-2025

High Pressure Fuel Injection Pump Assy For ISUZU 6H04 294050-0021 294050-0022 294050-0023 294050-0024 294050-0025 8-97602049-9

Images:

USD 384.18

[19-May-2025]

Scheme ###:

| 000. | [01] | 29405-00021 | PUMP ASSY, SUPPLY | 8-97602049-2 |

| 000. | [01] | 29405-00023 | PUMP ASSY, SUPPLY | 8-97602049-3 |

| 000. | [01] | 29405-00024 | PUMP ASSY, SUPPLY | 8-97602049-4 |

| 000. | [01] | 29405-00025 | PUMP ASSY, SUPPLY | 8-97602049-5 |

| 000. | [01] | 29405-00026 | PUMP ASSY, SUPPLY | 8-97602049-6 |

| 000. | [01] | 29405-00027 | PUMP ASSY, SUPPLY | 8-97602049-7 |

| 001. | [01] | 29410-05700 | HOUSING SUB-ASSY, | |

| 001. | [01] | 29410-05400 | HOUSING SUB-ASSY, | |

| 001. | [01] | 29410-05170 | HOUSING SUB-ASSY, | |

| 001. | [01] | 29410-05030 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-15010 | CAMSHAFT, SUPPLY P | |

| 003. | [01] | 29419-15070 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10040 | KEY, WOODRUFF | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-05000 | RING SUB-ASSY, CAM | |

| 005. | [01] | 29417-05011 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-05050 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05070 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05030 | COVER SUB-ASSY, BE | |

| 006. | [01] | 29412-05010 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90110 | BOLT, SOCKET | 8-97140853-0 |

| 008. | [02] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-35010 | PLATE, FEED PUMP, | |

| 010. | [01] | 29418-35030 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-45010 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00010 | ROTOR SET, FEED PU | |

| 014. | [05] | 09644-90050 | BOLT, SOCKET | |

| 015. | [02] | 29409-00120 | ELEMENT KIT, SUPPL | |

| 015. | [01] | 29409-00240 | ELEMENT KIT, SUPPL | |

| 015. | [01] | 29409-00350 | ELEMENT KIT, SUPPL | |

| 015. | [01] | 29409-00880 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00870 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00340 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00230 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00130 | ELEMENT KIT, SUPPL | |

| 017. | [03] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [03] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [03] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [12] | 29419-90010 | BOLT, SOCKET | |

| 021. | [01] | 29409-00250 | ELEMENT KIT, SUPPL | |

| 021. | [01] | 29409-00360 | ELEMENT KIT, SUPPL | |

| 021. | [01] | 29409-00890 | ELEMENT KIT, SUPPL | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 032. | [01] | 17973-00020 | SENSOR, FUEL TEMPE | 8-97216283-0 |

| 033. | [01] | 29420-00080 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00680 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50010 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00130 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 036. | [02] | 29401-05060 | PIPE, SUPPLY PUMP | |

| 036. | [02] | 29401-05030 | PIPE, SUPPLY PUMP | |

| 036. | [02] | 29401-05010 | PIPE, SUPPLY PUMP | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 09737-00040 | FILTER SUB-ASSY | |

| 039. | [01] | 29419-80180 | O-RING, SUPPLY PUM | |

| 041. | [01] | 09543-80010 | SCREW, HOLLOW | |

| 041. | [01] | 09543-80170 | SCREW, HOLLOW | 8-97351388-0 |

| 042. | [02] | 94901-02530 | WASHER | 8-97602218-0 |

| 043. | [01] | 94919-80260 | COLLAR, PRESSBOARD | |

| 044. | [01] | 94918-00310 | SCREW, HOLLOW | 5-15759003-0 |

| 045. | [02] | 94901-02490 | WASHER | 1-15619507-0 |

| 046. | [01] | 94919-80270 | COLLAR, PRESSBOARD | |

| 047. | [02] | 09031-70060 | PLUG, SCREW | |

| 048. | [02] | 09806-50020 | GASKET | |

| 052. | [01] | 09001-40160 | CAP, VALVE HOLDER | |

| 101. | [01] | 29400-90070 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90020 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90050 | OVERHAUL KIT, SUPP |

Include in #3:

29405-00025

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29405-00025 | 8-97602049 | PUMP ASSY, SUPPLY |

Information:

Marine Engine Performance Analysis Report (PAR)

Today's marine user is concerned with performance, cost of operation and satisfactory engine life. Traditionally, vessel performance has been directly related to the propulsion engine, when in fact the engine is only one of numerous factors influencing the propulsion system.To verify the condition of the propulsion system, Caterpillar has developed the Marine Engine Performance Analysis Report (PAR) program. Marine Engine PAR is an in-vessel test procedure, performed and evaluated by Caterpillar certified Marine Analysts under normal or bollard operating conditions, comparing the performance of all marine engine systems to original factory test cell specifications.When Marine Engine PAR testing is conducted at Sea Trial, it can assure you of a quality installation that confirms hull, rudders, propeller, marine transmission, ventilation and cooling systems are all properly matched for optimum performance and fuel efficiency.Caterpillar additionally recommends regularly scheduled (see Maintenance Schedule) Marine Engine PAR analyses to maintain optimum performance. Periodic PAR analyses can define propulsion system deterioration and aid in fine tuning the maintenance, repair and overhaul schedules, which will provide you the most economical and efficient cost of operation.

Today's marine user is concerned with performance, cost of operation and satisfactory engine life. Traditionally, vessel performance has been directly related to the propulsion engine, when in fact the engine is only one of numerous factors influencing the propulsion system.To verify the condition of the propulsion system, Caterpillar has developed the Marine Engine Performance Analysis Report (PAR) program. Marine Engine PAR is an in-vessel test procedure, performed and evaluated by Caterpillar certified Marine Analysts under normal or bollard operating conditions, comparing the performance of all marine engine systems to original factory test cell specifications.When Marine Engine PAR testing is conducted at Sea Trial, it can assure you of a quality installation that confirms hull, rudders, propeller, marine transmission, ventilation and cooling systems are all properly matched for optimum performance and fuel efficiency.Caterpillar additionally recommends regularly scheduled (see Maintenance Schedule) Marine Engine PAR analyses to maintain optimum performance. Periodic PAR analyses can define propulsion system deterioration and aid in fine tuning the maintenance, repair and overhaul schedules, which will provide you the most economical and efficient cost of operation.