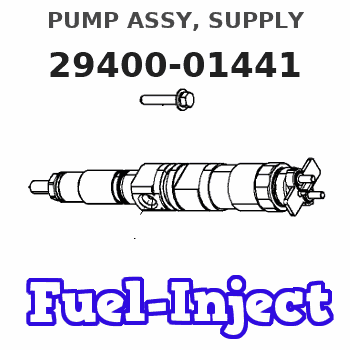

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

HP3 Fuel Pump 294000-1441 294000-1440 For 22100-E0540-A Diesel Injection Pump 22100-E0540

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

VDGOGHCN Precisely match the car model, easy to install, without complicated debugging, and can be used by direct replacement. || It can respond quickly to different working conditions of the engine, adjust the fuel injection quantity in time and ensure the smooth operation of the engine. || Accurately control the fuel injection quantity and time, so as to make the fuel burn fully, reduce the fuel consumption and improve the dynamic performance of the vehicle. || It has strong pressure output ability, which ensures that fuel can enter the engine combustion chamber accurately and efficiently, and improves combustion efficiency. || Advanced manufacturing technology and high-quality materials are adopted to effectively reduce vibration and noise during operation and ensure the stability of fuel injection process.

HP3 Fuel Pump 294000-1441 294000-1440 For 22100-E0540-A Diesel Injection Pump 22100-E0540

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

Common Rail Fuel Injection Pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 22100-E0541

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

VZUPNFAJ Fuel injection pump: advanced manufacturing technology can effectively improve the accuracy of fuel injection, keep the engine running stably and efficiently, and reduce fuel consumption. || Fuel injection pump: manufactured in strict accordance with automobile production standards, and the internal components are accurately matched to ensure that fuel is injected into the engine cylinder in time and accurately. || Fuel injection pump: perfect for your car, made of high-strength materials, with good wear resistance, and can work stably even in harsh environment. || Fuel injection pump: with excellent fuel metering function, it can adjust the fuel injection quantity in real time according to the working condition of the engine, and significantly enhance the power output of the engine. || Fuel injection pump: after strict testing, it has stable and reliable performance, can withstand high pressure and high load working environment, and provide continuous and stable fuel supply for the engine.

You can express buy:

USD 395.36

14-06-2025

14-06-2025

Diesel fuel injection pump 294000-1440 294000-1441 294000-1442 294000-2700 294000-2701 22100-E0540 for HINO N04C

USD 394.23

19-05-2025

19-05-2025

HP3 fuel pump 294000-1441 294000-1440 for 22100-E0540-A Diesel Injection Pump 22100-E0540

Images:

USD 384.18

[19-May-2025]

USD 550

[13-May-2025]

USD 437.61

[13-May-2025]

USD 404.03

[14-Jun-2025]

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-01441 | 22100-E054 | PUMP ASSY, SUPPLY |

Information:

Engine (Captive)C9.3 (S/N: MME1-UP)Industrial EngineC9.3 (S/N: C9N1-UP)Introduction

Do not perform any procedure that is outlined in this Special Instruction until you read and understand the information that is contained in this document.Safety

Contact with high pressure fuel may cause personal injury or death. Wait 60 seconds after the engine has stopped to allow fuel pressure to purge before any service or repair is performed on the engine fuel lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and mandates.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Contact with high pressure fuel may cause fluid penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

Required Tools

Table 1

Required Tools

Tool Part Number Part Name Qty

A

(1) 208-0888 Engine Turning Tool 1

B

(2) 5P-7305 Engine Turning Tool 1

5P-7306 Shaft Housing 1

C

(3) 350-7549 Engine Turning Tool 1

D 136-4632 Timing Pin 1

208-9388 Adapter 1

139-7064 Timing Pin Adapter 1

208-9387 Timing Pin Optional Longer Pin 1

E 294-3031 Fuel Pump Pinch Bolt 1

(1) The tooling is designed to turn the crankshaft in engines that are equipped with rear PTO. The tool engages the forward spline of upper gear of the PTO.

(2) The tooling is designed to turn the crankshaft in engines that are equipped with standard electric starters.

(3) The tooling is designed to turn the crankshaft in engines that have limited access to the flywheel housing. The tool engages all four bolt heads which are located in the front vibration damper.Removing the Fuel Injection Pump

Note: Cleanliness is a critical factor. Clean the exterior of the components before you begin the removal procedure. This action will help to prevent dirt from entering the internal mechanism.Note: Do not remove the valve mechanism cover at any time during this procedure.

Illustration 1 g02112896

Flywheel housing

Illustration 2 g06012763

Illustration 3 g02112894

Remove plug (X) from the timing hole that is located in the flywheel housing. Install the assembled timing pin (D) into the timing hole.

Use Tooling (A) or (B) to rotate the flywheel. Turn the flywheel in the direction of engine rotation. The direction of engine rotation is clockwise, as the engine is viewed from the vibration damper. Turn the vibration damper and the flywheel until the timing pin engages with the threaded hole in the flywheel.Note: If the flywheel is turned beyond the point of engagement, the flywheel must be turned in the direction that is reverse of normal engine rotation. Turn the flywheel by approximately 30 degrees. Then turn the flywheel in the direction of normal rotation until the timing pin engages with the threaded hole.

Remove all necessary components to access the fuel injection pump.

Do not perform any procedure that is outlined in this Special Instruction until you read and understand the information that is contained in this document.Safety

Contact with high pressure fuel may cause personal injury or death. Wait 60 seconds after the engine has stopped to allow fuel pressure to purge before any service or repair is performed on the engine fuel lines.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Dispose of all fluids according to local regulations and mandates.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Contact with high pressure fuel may cause fluid penetration and burn hazards. High pressure fuel spray may cause a fire hazard. Failure to follow these inspection, maintenance and service instructions may cause personal injury or death.

Required Tools

Table 1

Required Tools

Tool Part Number Part Name Qty

A

(1) 208-0888 Engine Turning Tool 1

B

(2) 5P-7305 Engine Turning Tool 1

5P-7306 Shaft Housing 1

C

(3) 350-7549 Engine Turning Tool 1

D 136-4632 Timing Pin 1

208-9388 Adapter 1

139-7064 Timing Pin Adapter 1

208-9387 Timing Pin Optional Longer Pin 1

E 294-3031 Fuel Pump Pinch Bolt 1

(1) The tooling is designed to turn the crankshaft in engines that are equipped with rear PTO. The tool engages the forward spline of upper gear of the PTO.

(2) The tooling is designed to turn the crankshaft in engines that are equipped with standard electric starters.

(3) The tooling is designed to turn the crankshaft in engines that have limited access to the flywheel housing. The tool engages all four bolt heads which are located in the front vibration damper.Removing the Fuel Injection Pump

Note: Cleanliness is a critical factor. Clean the exterior of the components before you begin the removal procedure. This action will help to prevent dirt from entering the internal mechanism.Note: Do not remove the valve mechanism cover at any time during this procedure.

Illustration 1 g02112896

Flywheel housing

Illustration 2 g06012763

Illustration 3 g02112894

Remove plug (X) from the timing hole that is located in the flywheel housing. Install the assembled timing pin (D) into the timing hole.

Use Tooling (A) or (B) to rotate the flywheel. Turn the flywheel in the direction of engine rotation. The direction of engine rotation is clockwise, as the engine is viewed from the vibration damper. Turn the vibration damper and the flywheel until the timing pin engages with the threaded hole in the flywheel.Note: If the flywheel is turned beyond the point of engagement, the flywheel must be turned in the direction that is reverse of normal engine rotation. Turn the flywheel by approximately 30 degrees. Then turn the flywheel in the direction of normal rotation until the timing pin engages with the threaded hole.

Remove all necessary components to access the fuel injection pump.