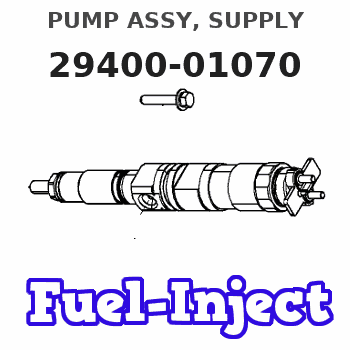

Information pump assy, supply

PUMP ASSY, SUPPLY

EA

- *1 SIAM DENSO PRODUCTION SM294000-107#

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Adfghjk HP3 Common Rail Fuel Injection Pump 294000-0661, 1460A022, 294000-0660, 1460A059, 1460A040, 294000-1260, Compatible with Mitsubishi Pajero 4M41, OEM-Level Diesel Pump Assembly(294000-0661)

Adfghjk HP3 High Pressure Common Rail Fuel Injection Pump 294000-0661】 Compatible with Mitsubishi Pajero Mitsubishi Pajero 4M41 design, factory level compatibility, accurate matching of fuel pressure and flow. || High-pressure common rail technology: ±1.5% injection error, optimize combustion efficiency, reduce carbon and NOx emissions. || Corrosion-resistant reinforced structure: aerospace-grade alloy steel core and ceramic-coated valve body, resistant to 2200Bar high pressure and diesel corrosion, with a life span of up to 180,000 kilometers. || Plug and Play Design: Integrated assembly directly replaces the original pump body, with 100% matching interface, 35 minutes quick installation without professional tools. || Strict quality control certification: ISO 9001 certified, compatible with Pajero 4M41 engine, compatible model: 1460A022/294000-0660 (please verify fitment before installation).

Adfghjk HP3 High Pressure Common Rail Fuel Injection Pump 294000-0661】 Compatible with Mitsubishi Pajero Mitsubishi Pajero 4M41 design, factory level compatibility, accurate matching of fuel pressure and flow. || High-pressure common rail technology: ±1.5% injection error, optimize combustion efficiency, reduce carbon and NOx emissions. || Corrosion-resistant reinforced structure: aerospace-grade alloy steel core and ceramic-coated valve body, resistant to 2200Bar high pressure and diesel corrosion, with a life span of up to 180,000 kilometers. || Plug and Play Design: Integrated assembly directly replaces the original pump body, with 100% matching interface, 35 minutes quick installation without professional tools. || Strict quality control certification: ISO 9001 certified, compatible with Pajero 4M41 engine, compatible model: 1460A022/294000-0660 (please verify fitment before installation).

High Pressure Pump 294000-1070 1460A040 294000-1260 1460A059 Compatible For Pajero 4M41 HP Di-D TD 4WD

BKAYOLOF Reduce particulate emissions: The high-pressure fuel pump can fully atomize the fuel and reduce the generation of incomplete combustion particles. || Extend engine life: Good combustion effect and stable operation, reduce the internal carbon accumulation and wear of the engine, thus extending the service life of the engine. || Compact structure: high-pressure fuel pumps have a compact design, small size, light weight, easy to install in the engine compartment, saving space. || Strong self-priming ability: with self-priming characteristics, no external water absorption can be operated, even in the presence of air or gas in the fuel system, it can work normally. || High Pressure Pump 294000-1070 1460A040 294000-1260 1460A059 Compatible For Pajero 4M41 HP Di-D TD 4WD

BKAYOLOF Reduce particulate emissions: The high-pressure fuel pump can fully atomize the fuel and reduce the generation of incomplete combustion particles. || Extend engine life: Good combustion effect and stable operation, reduce the internal carbon accumulation and wear of the engine, thus extending the service life of the engine. || Compact structure: high-pressure fuel pumps have a compact design, small size, light weight, easy to install in the engine compartment, saving space. || Strong self-priming ability: with self-priming characteristics, no external water absorption can be operated, even in the presence of air or gas in the fuel system, it can work normally. || High Pressure Pump 294000-1070 1460A040 294000-1260 1460A059 Compatible For Pajero 4M41 HP Di-D TD 4WD

MOMOBM HP3 High Pressure Diesel Fuel Pump Compatible for Mitsubishi Pajero 4M41 HP Di-D TD 4WD,OEM 1460A040 294000-1070 1460A059 294000-1260,Automotive Oil Pump Assembly

MOMOBM OEM NO:1460A059,1460A040,294000-1070,294000-1260 || PRECISION PARTS: Direct Replacement OEM High Pressure Fuel Pump - Compatible with Mitsubishi Pajero 4M41 HP Di-D TD 4WD || EXTRA LONG LIFE DESIGN: Rigorously Tested-Double Carbon Brushes and Corrosion Resistant Housing to meet factory specifications-No modifications required, eliminating the risk of fuel leakage || Efficient Fuel Delivery System: Reinforced stainless steel pump core + ceramic coated pistons for optimised combustion performance - Enhanced fuel atomisation to reduce engine knock and increase MPG || Plug & Play Installation Includes complete bolt-on kit (gaskets/seals/bolts)

MOMOBM OEM NO:1460A059,1460A040,294000-1070,294000-1260 || PRECISION PARTS: Direct Replacement OEM High Pressure Fuel Pump - Compatible with Mitsubishi Pajero 4M41 HP Di-D TD 4WD || EXTRA LONG LIFE DESIGN: Rigorously Tested-Double Carbon Brushes and Corrosion Resistant Housing to meet factory specifications-No modifications required, eliminating the risk of fuel leakage || Efficient Fuel Delivery System: Reinforced stainless steel pump core + ceramic coated pistons for optimised combustion performance - Enhanced fuel atomisation to reduce engine knock and increase MPG || Plug & Play Installation Includes complete bolt-on kit (gaskets/seals/bolts)

You can express buy:

USD 380.8

29-05-2025

29-05-2025

HP3 Diesel Common Rail Fuel Injection Pump 294000-1070 1460A040 For Mitsubishi Engine 4M41

USD 495

13-05-2025

13-05-2025

High Pressure Pump For Mitsubishi Pajero 4M41 HP Di-D TD 4WD Diesel Injection Pump 294000-1070 1460A040 294000-1260 1460A059

Images:

USD 426.76

[13-May-2025]

USD 392.4

[13-May-2025]

USD 384.18

[19-May-2025]

USD 352.04

[19-May-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-01070 |

| 002. | OVERHAUL KIT, SUPP | 29400-90080 |

Scheme ###:

| 000. | [01] | 29400-01070 | PUMP ASSY, SUPPLY | 1460A040 |

| 001. | [01] | 29410-01260 | HOUSING SUB-ASSY, | SM |

| 002. | [02] | 29417-80060 | WASHER, CAMSHAFT | SM |

| 003. | [01] | 29419-10060 | CAMSHAFT, SUPPLY P | SM |

| 003. | [01] | 29419-10110 | CAMSHAFT, SUPPLY P | SM |

| 004. | [01] | 29402-10040 | KEY, WOODRUFF | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-00150 | RING SUB-ASSY, CAM | SM |

| 005. | [01] | 29417-00260 | RING SUB-ASSY, CAM | SM |

| 006. | [01] | 29412-00330 | COVER SUB-ASSY, BE | SM |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90380 | BOLT, SOCKET | SM |

| 008. | [01] | 29419-80120 | O-RING, SUPPLY PUM | SM |

| 009. | [02] | 29419-80100 | O-RING, SUPPLY PUM | SM |

| 010. | [01] | 29418-30200 | PLATE, FEED PUMP, | SM |

| 011. | [01] | 29418-40160 | COVER, FEED PUMP | SM |

| 012. | [01] | 29418-70030 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70050 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00100 | ROTOR SET, FEED PU | SM |

| 014. | [05] | 09644-90370 | BOLT, SOCKET | SM |

| 015. | [01] | 29409-01040 | ELEMENT KIT, SUPPL | SM |

| 015. | [01] | 29409-00530 | ELEMENT KIT, SUPPL | SM |

| 015. | [01] | 29409-00300 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-00290 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-00560 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-01050 | ELEMENT KIT, SUPPL | SM |

| 017. | [02] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [02] | 29419-80080 | O-RING, SUPPLY PUM | SM |

| 019. | [02] | 29419-80110 | O-RING, SUPPLY PUM | SM |

| 020. | [06] | 29419-90030 | BOLT, SOCKET | SM |

| 031. | [01] | 29419-80150 | O-RING, SUPPLY PUM | SM |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00660 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50020 | O-RING, SOLENOID | SM |

| 035. | [01] | 29416-00120 | VALVE SUB-ASSY, RE | SM |

| 035. | [01] | 29416-00160 | VALVE SUB-ASSY, RE | SM |

| 035. | [01] | 29416-00210 | VALVE SUB-ASSY, RE | SM |

| 035-001. | [01] | 29419-80130 | O-RING, SUPPLY PUM | SM |

| 035-002. | [01] | 29419-80140 | O-RING, SUPPLY PUM | SM |

| 036. | [01] | 29401-00121 | PIPE, SUPPLY PUMP | SM |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 29411-50031 | PLUG, FILTER | SM |

| 039. | [01] | 29411-70020 | GASKET, PLUG | SM |

| 040. | [01] | 09737-00050 | FILTER SUB-ASSY | SM |

| 041. | [01] | 29419-80160 | O-RING, SUPPLY PUM | SM |

| 052. | [01] | 09001-45170 | CAP, VALVE HOLDER | SM |

| 053. | [01] | 09808-10100 | COVER, RUBBER | SM |

| 054. | [01] | 09808-10110 | COVER, RUBBER | SM |

| 101. | [01] | 29400-90010 | OVERHAUL KIT, SUPP | SM |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | SM |

| 200. | [01] | 29400-90080 | OVERHAUL KIT, SUPP | SM |

Include in #3:

29400-01070

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-01070 | 1460A040 | PUMP ASSY, SUPPLY | |

| 1460A040 | MITSUBISHI | PUMP ASSY SUPPLY |

Information:

3. Remove the connecting rod caps (1) from these pistons, and push the pistons upward until the rings clear the cylinder liner. 4. Remove the two pistons.5. Repeat Step 2 through 4 for the remaining pistons.Install Pistons

1. Thoroughly lubricate the crankshaft bearing journals and cylinder liners with clean SAE 30 engine oil.2. Lubricate the piston rings and connecting rod bearings with clean SAE 30 engine oil. 3. Using compressor (A), install the pistons with "V" mark on piston aligned with "V" mark on cylinder block. Guide the lower end of the rod over the crankshaft journal to prevent damage to the crankshaft.4. Lubricate the threads of cap retaining bolts with clean SAE 30 engine oil.5. Position the caps on the connecting rods, and install retaining nuts. Tighten nuts initially to 30 3 lb. ft. (4,1 0,4 mkg). Mark the nut and end of bolt, and tighten nut an additional 90° from mark.

When installing connecting rod cap, be sure that the number marked on side of cap is adjacent to and corresponds to the number marked on side of connecting rod.

6. Rotate the crankshaft until the next two bearing journals are at bottom dead center.7. Repeat Steps 2 through 5 for the remaining two pistons.concluding steps: a) install oil pumpb) install cylinder head assemblyDisassemble Pistons

preparatory step: a) remove pistons 1. Remove piston pin retaining rings (2).2. Remove piston pin (1) and remove piston from the connecting rod. 3. Remove the piston rings using ring expander (A).Assemble Pistons

1. Using ring expander (A), install the piston rings. The two compression rings are marked "UP - 1" and "UP - 2". The rings must be installed with these marks toward the top of the piston with "UP - 1" being the top ring. After all three rings have been installed on piston, stagger the ring caps 120° apart.2. Lubricate the piston pin with clean SAE 30 engine oil. 3. Position the piston on the connecting rod with the "V" mark (2) on the piston and number (1) on the connecting rod on the same side.4. Install the piston pin retaining rings. Make certain the retaining rings are seated in their grooves.concluding step: a) install pistons

1. Thoroughly lubricate the crankshaft bearing journals and cylinder liners with clean SAE 30 engine oil.2. Lubricate the piston rings and connecting rod bearings with clean SAE 30 engine oil. 3. Using compressor (A), install the pistons with "V" mark on piston aligned with "V" mark on cylinder block. Guide the lower end of the rod over the crankshaft journal to prevent damage to the crankshaft.4. Lubricate the threads of cap retaining bolts with clean SAE 30 engine oil.5. Position the caps on the connecting rods, and install retaining nuts. Tighten nuts initially to 30 3 lb. ft. (4,1 0,4 mkg). Mark the nut and end of bolt, and tighten nut an additional 90° from mark.

When installing connecting rod cap, be sure that the number marked on side of cap is adjacent to and corresponds to the number marked on side of connecting rod.

6. Rotate the crankshaft until the next two bearing journals are at bottom dead center.7. Repeat Steps 2 through 5 for the remaining two pistons.concluding steps: a) install oil pumpb) install cylinder head assemblyDisassemble Pistons

preparatory step: a) remove pistons 1. Remove piston pin retaining rings (2).2. Remove piston pin (1) and remove piston from the connecting rod. 3. Remove the piston rings using ring expander (A).Assemble Pistons

1. Using ring expander (A), install the piston rings. The two compression rings are marked "UP - 1" and "UP - 2". The rings must be installed with these marks toward the top of the piston with "UP - 1" being the top ring. After all three rings have been installed on piston, stagger the ring caps 120° apart.2. Lubricate the piston pin with clean SAE 30 engine oil. 3. Position the piston on the connecting rod with the "V" mark (2) on the piston and number (1) on the connecting rod on the same side.4. Install the piston pin retaining rings. Make certain the retaining rings are seated in their grooves.concluding step: a) install pistons