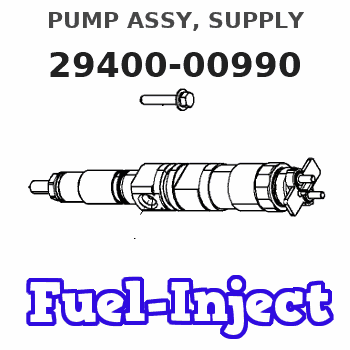

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 294000-0990 2940000990 Compatible with Mitsubishi Diesel Engine 4N13

Starhycfa Product name:Fuel Injection Pump || Part Number:294000-0990 2940000990 || APPlication:Compatible with Mitsubishi Diesel Engine 4N13 || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

Starhycfa Product name:Fuel Injection Pump || Part Number:294000-0990 2940000990 || APPlication:Compatible with Mitsubishi Diesel Engine 4N13 || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

Compatible with Mitsubishi Diesel Engine 4N13 Fuel Injection Pump 1460A043 294000-0990

KoovDem Part Number: 1460A043 294000-0990 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || The 4N13 engine is a reliable and high-performing four-cylinder engine with advanced technology like turbocharging and direct injection, providing impressive power and efficiency. Its compact and lightweight design makes it suitable for various vehicles, offering a smooth driving experience and fuel efficiency. Overall, the 4N13 engine is a great choice for any automotive needs. || Suitable for use with Mitsubishi Diesel Engine 4N13. || Package includes: 1 piece of Fuel Injection Pump 1460A043 294000-0990.

KoovDem Part Number: 1460A043 294000-0990 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || The 4N13 engine is a reliable and high-performing four-cylinder engine with advanced technology like turbocharging and direct injection, providing impressive power and efficiency. Its compact and lightweight design makes it suitable for various vehicles, offering a smooth driving experience and fuel efficiency. Overall, the 4N13 engine is a great choice for any automotive needs. || Suitable for use with Mitsubishi Diesel Engine 4N13. || Package includes: 1 piece of Fuel Injection Pump 1460A043 294000-0990.

IMIFAFTAbT 1460A036 1460A043 294000-0990 l294000-0991 Fuel injection pump Fits for Mitsubishi Lancer ASX 4N13 Engine 1.8 DI-D

IMIFAFTAbT Product Name: 1460A036 1460A043 294000-0990 l294000-0991 Fuel injection pump || Part number: 1460A036 1460A043 294000-0990 l294000-0991 || Fits for Mitsubishi Lancer ASX 4N13 Engine 1.8 DI-D || 1 PCS Fuel injection pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 1460A036 1460A043 294000-0990 l294000-0991 Fuel injection pump || Part number: 1460A036 1460A043 294000-0990 l294000-0991 || Fits for Mitsubishi Lancer ASX 4N13 Engine 1.8 DI-D || 1 PCS Fuel injection pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

You can express buy:

USD 394.79

19-05-2025

19-05-2025

High quality OEM Auto Parts Wholesale fuel injection pump parts 1460A043 294000-0990

USD 428.15

13-05-2025

13-05-2025

CR Pump Diesel Injector Common Rail Fuel Pump 294000-0990 1460A043 for Mitsubishi 4N13 engine

Images:

USD 380.88

[04-May-2025]

USD 71.39

[19-May-2025]

USD 384.18

[19-May-2025]

USD 474.98

[19-May-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-00990 |

| 002. | OVERHAUL KIT, SUPP | 29400-90031 |

Scheme ###:

| 000. | [01] | 29400-00991 | PUMP ASSY, SUPPLY | 1460A043 |

| 001. | [01] | 29410-01230 | HOUSING SUB-ASSY, | |

| 002. | [01] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29417-80080 | WASHER, CAMSHAFT | |

| 004. | [01] | 29419-10070 | CAMSHAFT, SUPPLY P | |

| 005. | [01] | 29417-00210 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-00440 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70020 | SEAL, OIL | |

| 007. | [06] | 09644-90110 | BOLT, SOCKET | ME736324 |

| 008. | [01] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-30160 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-40080 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70040 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [05] | 09644-90050 | BOLT, SOCKET | |

| 015. | [01] | 29409-00510 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00520 | ELEMENT KIT, SUPPL | |

| 017. | [02] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [02] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [02] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [06] | 29419-90010 | BOLT, SOCKET | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-02960 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60030 | O-RING, VALVE | |

| 034. | [01] | 29428-50010 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00210 | VALVE SUB-ASSY, RE | |

| 035. | [01] | 29416-00160 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 29411-50010 | PLUG, FILTER | |

| 039. | [01] | 29411-70010 | GASKET, PLUG | |

| 040. | [01] | 09737-00010 | FILTER SUB-ASSY | |

| 041. | [01] | 09604-90460 | O-RING | |

| 052. | [02] | 09001-40180 | CAP, VALVE HOLDER | |

| 053. | [01] | 09808-10020 | COVER, RUBBER | |

| 054. | [01] | 09646-80060 | CAP RUBBER | |

| 055. | [01] | 29419-80260 | O-RING, SUPPLY PUM | |

| 101. | [01] | 29400-90010 | OVERHAUL KIT, SUPP | |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90031 | OVERHAUL KIT, SUPP |

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00990 | PUMP ASSY, SUPPLY | ||

| 1460A043 | MITSUBISHI | PUMP ASSY, SUPPLY | |

| 1460A036 | MITSUBISHI | PUMP ASSY SUPPLY |

Information:

Storage Procedure

1. Clean the outside of the engine and repaint areas that have paint damage with a good quality paint.2. Remove the batteries and use them in some other place or put them in storage where they can be checked and electrically charged again when needed. If the batteries are not removed, wash the tops. Put an electrical charge to the battery to a specific gravity of 1.275. Disconnect the battery terminals. Put a plastic cover over the battery.3. Loosen all fan, alternator belts, etc. Attach a tag to indicate what work has been done.4. Put a waterproof cover over engines with enclosures stored outdoors. Make the cover tight, but loose enough to allow air to circulate around the engine to prevent damage to exposed metal parts from condensation. Remove the waterproof cover every two or three months and check the engine for corrosion. If the engine has signs of corrosion at the check period, follow the protection procedure again. To operate the engine, it is not necessary to remove the preservative oil mixture. If a compartment under protection of VCI vapors is opened, put more VCI mixture in to make up for the vapor loss. Install all covers and/or put tape over all openings, air intake, exhaust openings, flywheel housing, crankcase breathers, dipstick tubes, etc. Make sure all covers are air tight and weatherproof. Use a waterproof, weather resistant tape.5. Put lubricant on all points given in the Lubrication and Maintenance Chart.6. Put a heavy amount of multipurpose grease on all outside parts that move; rod threads, ball joints, linkage, etc.7. Oil and oil filter elements used less than 50 hours in the engine do not need to be changed. (Otherwise, change the oil, filling the engine to the "add oil" mark on the dipstick.) Add 3% to 4% of VCI oil per engine volume. If the engine is drained, install a mixture of 50% VCI oil and 50% engine oil in the crankcase and in all lubricating oil compartments at the rate of one part VCI oil mixture per fifteen parts of compartment capacity at full level. If possible, operate the engine three to five minutes. Put tape over all openings to seal VCI vapors in the engine. If necessary, drain some lubricant to add to the mixture.8. Remove any dirt from the air cleaner. Check all seals and gaskets.9. Remove the air filter elements. Turn the engine at cranking speed with throttle control in fuel OFF position, remove pressure plug for boost pressure and use a sprayer to add a mixture of 50% VCI oil and 50% engine oil. Minimum application rate is 5.5 milliliters per liter (3 oz. per

1. Clean the outside of the engine and repaint areas that have paint damage with a good quality paint.2. Remove the batteries and use them in some other place or put them in storage where they can be checked and electrically charged again when needed. If the batteries are not removed, wash the tops. Put an electrical charge to the battery to a specific gravity of 1.275. Disconnect the battery terminals. Put a plastic cover over the battery.3. Loosen all fan, alternator belts, etc. Attach a tag to indicate what work has been done.4. Put a waterproof cover over engines with enclosures stored outdoors. Make the cover tight, but loose enough to allow air to circulate around the engine to prevent damage to exposed metal parts from condensation. Remove the waterproof cover every two or three months and check the engine for corrosion. If the engine has signs of corrosion at the check period, follow the protection procedure again. To operate the engine, it is not necessary to remove the preservative oil mixture. If a compartment under protection of VCI vapors is opened, put more VCI mixture in to make up for the vapor loss. Install all covers and/or put tape over all openings, air intake, exhaust openings, flywheel housing, crankcase breathers, dipstick tubes, etc. Make sure all covers are air tight and weatherproof. Use a waterproof, weather resistant tape.5. Put lubricant on all points given in the Lubrication and Maintenance Chart.6. Put a heavy amount of multipurpose grease on all outside parts that move; rod threads, ball joints, linkage, etc.7. Oil and oil filter elements used less than 50 hours in the engine do not need to be changed. (Otherwise, change the oil, filling the engine to the "add oil" mark on the dipstick.) Add 3% to 4% of VCI oil per engine volume. If the engine is drained, install a mixture of 50% VCI oil and 50% engine oil in the crankcase and in all lubricating oil compartments at the rate of one part VCI oil mixture per fifteen parts of compartment capacity at full level. If possible, operate the engine three to five minutes. Put tape over all openings to seal VCI vapors in the engine. If necessary, drain some lubricant to add to the mixture.8. Remove any dirt from the air cleaner. Check all seals and gaskets.9. Remove the air filter elements. Turn the engine at cranking speed with throttle control in fuel OFF position, remove pressure plug for boost pressure and use a sprayer to add a mixture of 50% VCI oil and 50% engine oil. Minimum application rate is 5.5 milliliters per liter (3 oz. per