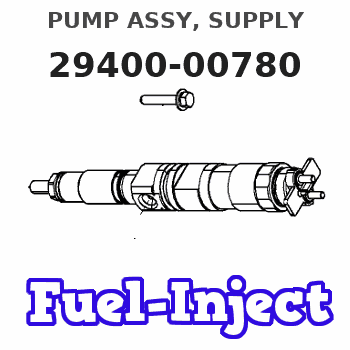

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 294000-0530 16700-VM00A 16700-EC00A for Nissan Engine YD25

FGNTWP Part Number:16700EC00A, 16700-EC00A, 16700VM00A, 16700-VM00A, 16700VM00D, 16700-VM00D, 16700VM01C, 16700-VM01C, 294000-0530, 294000-0780, 294000-0782, 294000-0785, 2940000530, 2940000780, 2940000782, 2940000785 || Applications:for Nissan Engine YD25

FGNTWP Part Number:16700EC00A, 16700-EC00A, 16700VM00A, 16700-VM00A, 16700VM00D, 16700-VM00D, 16700VM01C, 16700-VM01C, 294000-0530, 294000-0780, 294000-0782, 294000-0785, 2940000530, 2940000780, 2940000782, 2940000785 || Applications:for Nissan Engine YD25

Fuel injection pump 294000-0780 Fits for Nissian YD25 Engine DDTi 16700-VW01C

KoovDem Part Number: 16700-VW01C 294000-0780 16700VW01C 2940000780 || Product Name: 16700-VW01C 294000-0780 16700VW01C 2940000780 Fuel injection pump || Brand new items in pristine condition, never used or worn. Original packaging, untouched and ready to use or display. Perfect for gifts or personal use, guaranteed to meet expectations. Experience the joy of owning something completely untouched and perfect by getting your hands on these new items today. || Designed for the Nissan YD25 Engine, this high-quality DDTi engine component offers optimal performance and reliability. Precision engineering and durable materials ensure a perfect fit and long-lasting durability. Upgrade or replace with confidence in the enhanced efficiency and excellent performance this product provides for your Nissan vehicle. || Please ensure that the product model you intend to purchase matches our specifications before proceeding with your order. If you are uncertain, feel free to reach out to us for clarification. Thank you for your cooperation in avoiding unnecessary returns.

KoovDem Part Number: 16700-VW01C 294000-0780 16700VW01C 2940000780 || Product Name: 16700-VW01C 294000-0780 16700VW01C 2940000780 Fuel injection pump || Brand new items in pristine condition, never used or worn. Original packaging, untouched and ready to use or display. Perfect for gifts or personal use, guaranteed to meet expectations. Experience the joy of owning something completely untouched and perfect by getting your hands on these new items today. || Designed for the Nissan YD25 Engine, this high-quality DDTi engine component offers optimal performance and reliability. Precision engineering and durable materials ensure a perfect fit and long-lasting durability. Upgrade or replace with confidence in the enhanced efficiency and excellent performance this product provides for your Nissan vehicle. || Please ensure that the product model you intend to purchase matches our specifications before proceeding with your order. If you are uncertain, feel free to reach out to us for clarification. Thank you for your cooperation in avoiding unnecessary returns.

HP3 Fuel Injection Pump for Nissan YD25 D22 D40 2.5L Euro 4 Engine Nissian Navara Pathfinder R51 Pick-Up 16700-VM00A 16700VM00A 294000-0780

KoovDem Part Number: 294000-0780, 16700-VM00A, 16700VM00A, 16700-VM00B, 16700VM00B, 16700-VM00C, 16700VM00C, 16700-VM00D, 16700VM00D || Compatible Model: for Nissan YD25 D22 D40 2.5L Euro 4 Engine; for Nissian Navara 2.5L YD25, DDTi, D22, D40, NP300, dCi, Euro 4; for Nissian Pathfinder 2.5L YD25, D4, DDTi, dCi, Euro 4 || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

KoovDem Part Number: 294000-0780, 16700-VM00A, 16700VM00A, 16700-VM00B, 16700VM00B, 16700-VM00C, 16700VM00C, 16700-VM00D, 16700VM00D || Compatible Model: for Nissan YD25 D22 D40 2.5L Euro 4 Engine; for Nissian Navara 2.5L YD25, DDTi, D22, D40, NP300, dCi, Euro 4; for Nissian Pathfinder 2.5L YD25, D4, DDTi, dCi, Euro 4 || Effective and Reliable: Utilizing cutting-edge technology, this system delivers effective and reliable fuel supply, guaranteeing smooth vehicle performance. || Rugged and Dependable: With a track record of being rigorously tested and proven, this product offers durability and reliability, ensuring it operates consistently even in the harshest of environments. || Straightforward Installation: With a user-friendly interface, installing this product is a breeze. Simply plug it in and you're good to go, no technical expertise needed.

You can express buy:

USD 406

19-05-2025

19-05-2025

Injection Pump 294000-0780 294000-0781 094000-0783 294000-0785 16700 VM01A 16700-VM01C for NISSAN YD25 Pathfinder/Navara

USD 428.88

19-05-2025

19-05-2025

High Pressure Common Rail Diesel Injection Fuel Pump 294000-0780 16700-VM01C 16700VM01C for Nissian YD25

Images:

USD 399.82

[19-May-2025]

USD 391.58

[19-May-2025]

USD 715.51

[19-May-2025]

USD 722.63

[19-May-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-00780 |

| 001. | PUMP ASSY, SUPPLY | 29400-00780 |

| 002. | OVERHAUL KIT, SUPP | 29400-90080 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00780 | 16700VM00A | PUMP ASSY, SUPPLY | |

| 16700VM00D | NISSAN MOTOR | PUMP ASSY, SUPPLY | |

| 16700VM00A | NISSAN MOTOR | PUMP ASSY SUPPLY |

Information:

INJECTION NOZZLE (Right side illustrated)

1. Lines (eight, four each side). 2. Injection nozzles (eight, four each side). 3. Clamps (eight, four each side).4. Remove the adapter (4) and lift injection nozzle (2) out of the cylinder head.

ADAPTER AND NOZZLE REMOVAL

2. Injection nozzle. 4. Adapter. 5. O-ring seal. 6. O-ring seal.

Pull nozzle straight out, by hand, to remove. Slight twisting action is permissible if necessary. Never pry out a nozzle with a screwdriver or other similar tool.

Always replace O-ring seals (5) and (6) before installing nozzle.5. Use needle-nose pliers to remove carbon seal dam (8). Always install a new compression seal (7) and carbon seal dam (8) before installing injection nozzle.

REMOVING CARBON SEAL DAM (Typical Example)

7. Compression seal. 8. Carbon seal dam.Install Fuel Injection Nozzles

1. Be sure the bore in the cylinder head and fuel inlet fittings are clean.

Never install an injection nozzle that has been dropped, without first testing it with the 8S2242 Nozzle Tester Group. The injector tips are very hard and brittle and break easily.

2. Install a new compression seal and carbon seal dam. Use carbon seal dam installation tool (9) to install the carbon seal dam.

INSTALLING CARBON SEAL DAM (Typical Example)

9. 8S2252 Carbon Seal Dam Installation Tool.3. Install a new O-ring seal (6) on the injection nozzle (2) and a new O-ring seal (5) on the adapter (4).4. Install the injection nozzle (2) into the cylinder head using a twisting motion. Do not use lubricant in the cylinder head bore or on the nozzle body.

INSTALLING NOZZLE

2. Injection nozzle. 4. Adapter. 5. O-ring seal. 6. O-ring seal.

Do not bend the injector inlet connection when installing injector into cylinder head. Bending of the inlet connection creates tension on the injector and causes binding of the needle in the guide.

5. Install the adapter (4) and tighten the injection nozzle-to-adapter retaining nut. Tighten retaining nut to 30 5 lb. ft. (4.1 0.7 mkg). Hand tighten the fuel injection line.6. Install the injection nozzle clamp.7. Install the fuel return manifold and rocker arm assembly. Install retaining bolts and locks. Tighten bolts to 18 5 lb. ft. (2.5 0.7 mkg) and bend locks.8. Adjust the intake valve clearance to .015 in. (0.38 mm) and the exhaust valve clearance to .025 in. (0.64 mm).9. Install valve cover. Install mounting bolts and tighten to 120 24 lb. in. (138 28 cm.kg).10. Purge the fuel lines of air by motoring the engine until fuel, free of air, flows from the connections.11. Use 5P144 Fuel Line Socket to tighten the fuel line connections to 30 5 lb. ft. (4.1 0.7 mkg).12. Start the engine and correct any fuel leaks that may occur.