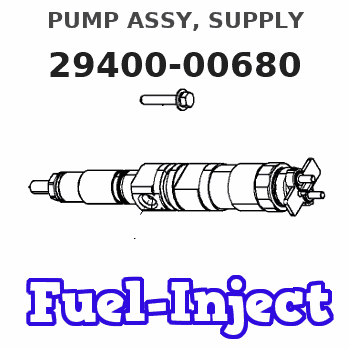

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Fuel Injection Pump 294000-0680 294000-0681 1111010A720-0000 Compatible For FAWDE CA4DL Engine

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 294000-0680 294000-0681 1111010A720-0000 Compatible For FAWDE CA4DL Engine

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 294000-0680 294000-0681 1111010A720-0000 Compatible For FAWDE CA4DL Engine

Diesel Fuel Injection Pump 294000-0680 294000-0681 1111010A720-0000 Compatible For FAWDE CA4DL Engine

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 294000-0680 294000-0681 1111010A720-0000 Compatible For FAWDE CA4DL Engine

VSQQGPSV Through high-precision pressure, fuel can be fully atomized, promoting complete combustion and improving fuel economy. || High precision manufacturing processes ensure the accuracy of fuel metering and injection. || Excellent design minimizes noise and vibration during operation, providing you with a quieter and more comfortable driving experience. || A good fuel injection pump is crucial for engine power, fuel efficiency, and fuel economy. || Diesel Fuel Injection Pump 294000-0680 294000-0681 1111010A720-0000 Compatible For FAWDE CA4DL Engine

Common Rail Pump 294000-0681 Fuel Injection Pump 294000-0680 Compatible With ISUZU

SYOTOE Stable fuel supply: it can continuously deliver fuel from the fuel tank to the engine to ensure that there will be no fuel shortage when the engine is running, so that the engine can run smoothly. || Adjustable pressure: it can provide fuel with appropriate pressure according to the requirements of different working conditions of the engine to ensure the fuel injection effect and the normal operation of the engine. || Sufficient flow rate: the oil transportation capacity per unit time is large, which can meet the fuel demand under the rated power condition of the engine, and can provide enough fuel even under high load or acceleration. || Quick response: the electric fuel pump can respond quickly according to the control signal of ECU, and realize the accurate control of fuel supply, so that the engine can get the required fuel in time under various working conditions. || Strong adaptability: there are many designs and configurations, which can adapt to different vehicle types and fuel system requirements, such as being installed inside or outside the fuel tank.

SYOTOE Stable fuel supply: it can continuously deliver fuel from the fuel tank to the engine to ensure that there will be no fuel shortage when the engine is running, so that the engine can run smoothly. || Adjustable pressure: it can provide fuel with appropriate pressure according to the requirements of different working conditions of the engine to ensure the fuel injection effect and the normal operation of the engine. || Sufficient flow rate: the oil transportation capacity per unit time is large, which can meet the fuel demand under the rated power condition of the engine, and can provide enough fuel even under high load or acceleration. || Quick response: the electric fuel pump can respond quickly according to the control signal of ECU, and realize the accurate control of fuel supply, so that the engine can get the required fuel in time under various working conditions. || Strong adaptability: there are many designs and configurations, which can adapt to different vehicle types and fuel system requirements, such as being installed inside or outside the fuel tank.

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00680 | 1111010720 | PUMP ASSY, SUPPLY | |

| 1111010A7200000 | FAWDE | PUMP ASSY SUPPLY | |

| 1111010A720000 | FAWDE | PUMP ASSY, SUPPLY | |

| 11110107200000 | FAWDE | PUMP ASSY, SUPPLY | |

| 1111010-720-000 | OTHERS | PUMP ASSY SUPPLY |

Information:

1-Inlet air pipe. 2-Exhaust elbow. 3-Turbocharger oil drain line. 4-Turbocharger oil supply line. 5-Turbocharger. 6-Fuel injection lines (six). 7-Heat shield. 8-Exhaust manifold (three sections).Turbocharger Removal And Installation

Refer to SERVICE GUIDE for Preliminary Information.

1-Exhaust elbow. 2-Turbocharger oil supply line. 3-Bolts and nuts (two each). 4-Bolts, locks and nuts (four each). 5-Turbocharger oil drain line. 6-Inlet air pipe. Apply 9M3710 Anti-Seize Compound to threads of bolts (3 and 4) when installing turbocharger.Turbocharger Disassembly And Assembly

8S9944 Turbine Holder.1,3,5 Remove nut (1). Position the compressor end of housing (5) in an oil bath so only impeller (3) is immersed in oil. Heat impeller to 350° F. (176° C.) for not longer than ten minutes. Remove unit from oil bath and press the shaft and turbine wheel from impeller (3).1,3,5 At installation, heat impeller (3) to a maximum of 350°F. (176°C.) for not longer than ten minutes and proceed as follows: For ease of impeller installation, place the turbine wheel end of center housing (5) in an 8S9944 Turbine Holder.a. Immediately install impeller (3) on shaft, install nut (1) and tighten it to 120 lb. in. (138,4 cm.kg).b. Allow impeller to cool to less than 150°F. (65, 49°C.) and remove nut (1).c. Clean and smooth the washer face of nut (1). Lightly oil the threads of turbine shaft and nut and install the nut.d. Tighten nut (1) to 20 lb. in. (23,0 cm.kg), then tighten an additional 120°.2 Coat threads with 9M3710 Anti-Seize Compound.4,5 Install thrust plate assembly (4) so oil hole aligns with oil hole in housing (5).