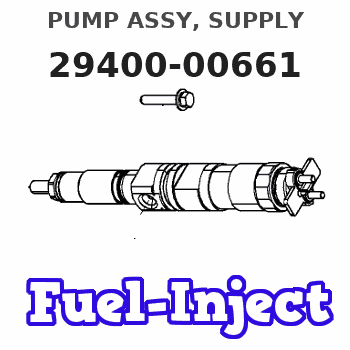

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

WZCNLXLX Fuel Injection Pump 294000-0661 2940000661 1460A022 for Mitsubishi 4M41 Engine

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:294000-0661 2940000661 1460A022 || Application:for Mitsubishi 4M41 Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:294000-0661 2940000661 1460A022 || Application:for Mitsubishi 4M41 Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

Adfghjk HP3 Common Rail Fuel Injection Pump 294000-0661, 1460A022, 294000-0660, 1460A059, 1460A040, 294000-1260, Compatible with Mitsubishi Pajero 4M41, OEM-Level Diesel Pump Assembly(294000-0661)

Adfghjk HP3 High Pressure Common Rail Fuel Injection Pump 294000-0661】 Compatible with Mitsubishi Pajero Mitsubishi Pajero 4M41 design, factory level compatibility, accurate matching of fuel pressure and flow. || High-pressure common rail technology: ±1.5% injection error, optimize combustion efficiency, reduce carbon and NOx emissions. || Corrosion-resistant reinforced structure: aerospace-grade alloy steel core and ceramic-coated valve body, resistant to 2200Bar high pressure and diesel corrosion, with a life span of up to 180,000 kilometers. || Plug and Play Design: Integrated assembly directly replaces the original pump body, with 100% matching interface, 35 minutes quick installation without professional tools. || Strict quality control certification: ISO 9001 certified, compatible with Pajero 4M41 engine, compatible model: 1460A022/294000-0660 (please verify fitment before installation).

Adfghjk HP3 High Pressure Common Rail Fuel Injection Pump 294000-0661】 Compatible with Mitsubishi Pajero Mitsubishi Pajero 4M41 design, factory level compatibility, accurate matching of fuel pressure and flow. || High-pressure common rail technology: ±1.5% injection error, optimize combustion efficiency, reduce carbon and NOx emissions. || Corrosion-resistant reinforced structure: aerospace-grade alloy steel core and ceramic-coated valve body, resistant to 2200Bar high pressure and diesel corrosion, with a life span of up to 180,000 kilometers. || Plug and Play Design: Integrated assembly directly replaces the original pump body, with 100% matching interface, 35 minutes quick installation without professional tools. || Strict quality control certification: ISO 9001 certified, compatible with Pajero 4M41 engine, compatible model: 1460A022/294000-0660 (please verify fitment before installation).

Fuel Injection Pump Compatible with Mitsubishi Engine 4M41 294000-0661 1460A022 2940000661

KoovDem Part Number: 294000-0661 1460A022 2940000661 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with Mitsubishi Engine 4M41. || Package includes: 1 piece of Fuel Injection Pump with OEM part numbers 294000-0661, 1460A022, and 2940000661.

KoovDem Part Number: 294000-0661 1460A022 2940000661 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with Mitsubishi Engine 4M41. || Package includes: 1 piece of Fuel Injection Pump with OEM part numbers 294000-0661, 1460A022, and 2940000661.

You can express buy:

USD 377.33

01-06-2025

01-06-2025

New Fuel injection pumps 294000-0660 294000-0661 1460A022 for Mitsubishi Pajero 4M41

USD 406

13-05-2025

13-05-2025

HP3 Common Rail Fuel Injection Pump 294000-0661 1460A022 294000-0660 for Mitsubishi Pajero 4M41

Images:

USD 401.64

[19-May-2025]

USD 384.45

[08-May-2025]

USD 386.96

[02-May-2025]

USD 2948.65

[27-May-2025]

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-00661 |

| 002. | OVERHAUL KIT, SUPP | 29400-90080 |

Scheme ###:

| 000. | [01] | 29400-00661 | PUMP ASSY, SUPPLY | 1460A022 |

| 001. | [01] | 29410-00791 | HOUSING SUB-ASSY, | SM |

| 002. | [02] | 29417-80060 | WASHER, CAMSHAFT | SM |

| 003. | [01] | 29419-10060 | CAMSHAFT, SUPPLY P | SM |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-00260 | RING SUB-ASSY, CAM | SM |

| 005. | [01] | 29417-00150 | RING SUB-ASSY, CAM | SM |

| 006. | [01] | 29412-00250 | COVER SUB-ASSY, BE | SM |

| 006. | [01] | 29412-00330 | COVER SUB-ASSY, BE | SM |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90380 | BOLT, SOCKET | SM |

| 008. | [01] | 29419-80120 | O-RING, SUPPLY PUM | SM |

| 009. | [02] | 29419-80100 | O-RING, SUPPLY PUM | SM |

| 010. | [01] | 29418-30200 | PLATE, FEED PUMP, | SM |

| 011. | [01] | 29418-40160 | COVER, FEED PUMP | SM |

| 012. | [01] | 29418-70030 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70050 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00100 | ROTOR SET, FEED PU | SM |

| 014. | [05] | 09644-90370 | BOLT, SOCKET | SM |

| 015. | [01] | 29409-01040 | ELEMENT KIT, SUPPL | SM |

| 015. | [01] | 29409-00530 | ELEMENT KIT, SUPPL | SM |

| 015. | [01] | 29409-00300 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-00290 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-00560 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-01050 | ELEMENT KIT, SUPPL | SM |

| 017. | [02] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [02] | 29419-80080 | O-RING, SUPPLY PUM | SM |

| 019. | [02] | 29419-80110 | O-RING, SUPPLY PUM | SM |

| 020. | [06] | 29419-90030 | BOLT, SOCKET | SM |

| 031. | [01] | 29419-80150 | O-RING, SUPPLY PUM | SM |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00160 | VALVE ASSY, SUCTIO | SM |

| 033. | [01] | 29420-00360 | VALVE ASSY, SUCTIO | SM |

| 033-001. | [01] | 29428-60030 | O-RING, VALVE | SM |

| 034. | [01] | 29428-50030 | O-RING, SOLENOID | SM |

| 035. | [01] | 29416-00120 | VALVE SUB-ASSY, RE | SM |

| 035. | [01] | 29416-00160 | VALVE SUB-ASSY, RE | SM |

| 035. | [01] | 29416-00210 | VALVE SUB-ASSY, RE | SM |

| 035-001. | [01] | 29419-80130 | O-RING, SUPPLY PUM | SM |

| 035-002. | [01] | 29419-80140 | O-RING, SUPPLY PUM | SM |

| 036. | [01] | 29401-00121 | PIPE, SUPPLY PUMP | SM |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 29411-50031 | PLUG, FILTER | SM |

| 039. | [01] | 29411-70020 | GASKET, PLUG | SM |

| 040. | [01] | 09737-00050 | FILTER SUB-ASSY | SM |

| 041. | [01] | 29419-80160 | O-RING, SUPPLY PUM | SM |

| 043. | [01] | 29425-90020 | GASKET, SOLENOID | |

| 052. | [01] | 09001-45170 | CAP, VALVE HOLDER | SM |

| 053. | [01] | 09808-10100 | COVER, RUBBER | SM |

| 054. | [01] | 09808-10110 | COVER, RUBBER | SM |

| 101. | [01] | 29400-90010 | OVERHAUL KIT, SUPP | SM |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | SM |

| 200. | [01] | 29400-90080 | OVERHAUL KIT, SUPP | SM |

Include in #3:

29400-00661

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00661 | 1460A022 | PUMP ASSY, SUPPLY |

Information:

(1) End play for the crankshaft ... .006 .003 in.(0.15 0.08 mm) Maximum permissible end play for the crankshaft (worn) ... .012 in.(0.30 mm)(2) Diameter of bearing surfaces (journals) for the connecting rods [standard, original size] ... 2.7500 .0004 in.(69.850 0.010 mm) Minimum permissible diameter (worn) ... 2.7486 in.(69.814 mm)Diameter of bearing surfaces (journals) for the connecting rods [.010 in. (0.25 mm) smaller than the original size] ... 2.7400 .0004 in.(69.596 0.010 mm)Minimum permissible diameter (worn) ... 2.7386 in.(69.560 mm)Diameter of bearing surfaces (journals) for the connecting rods [.020 in. (0.51 mm) smaller than the original size] ... 2.7300 .0004 in.(69.342 0.010 mm)Minimum permissible diameter (worn) ... 2.7286 in.(69.306 mm)(3) Diameter of bearing surfaces (journals) for the main bearings [standard, original size] ... 3.5000 .0005 in.(88.900 0.013 mm) Minimum permissible diameter (worn) ... 3.4985 in.(88.862 mm)Diameter of bearing surfaces (journals) for the main bearings [.010 in. (0.25 mm) smaller than the original size] ... 3.4900 .0005 in.(88.646 0.013 mm)Minimum permissible diameter (worn) ... 3.4885 in.(88.608 mm)Diameter of bearing surfaces (journals) for the main bearings [.020 in. (0.51 mm) smaller than the original size] ... 3.4800 .0005 in.(88.392 0.013 mm)Minimum permissible diameter (worn) ... 3.4785 in.(88.354 mm)Bore in main bearing ... 3.5030 .0010 in.(88.976 0.025 mm)Clearance between main-bearing and crankshaft bearing surface (journal) ... .0015 to .0045 in.(0.038 to 0.114 mm)Maximum permissible clearance between main bearing and crankshaft bearing surface (journal) ... .006 in.(0.15 mm)Maximum permissible run out (axial eccentricity) of the crankshaft, measured at the center main bearing surface (journal) ... .006 in.(0.15 mm)Maximum permissible run out (axial eccentricity) of the crankshaft, measured at No.2 and No.4 main bearing surfaces (journal) ... .003 in.(0.08 mm)(9L8122, 9L8123, 9L8400)

Before installing gear, get temperature of gear to a maximum of 300° F (149° C)(1) End play for the crankshaft ... .006 .003 in.(0.15 0.08 mm) Maximum permissible end play for the crankshaft (worn) ... .012 in.(0.30 mm)(2) Diameter of bearing surfaces (journals) for the connecting rods ... 2.7500 .0004 in.(69.850 0.010 mm) Minimum permissible diameter (worn) ... 2.7486 in.(69.814 mm)(3) Diameter of bearing surfaces (journals) for main bearings ... 3.5000 .0005 in.(88.900 0.013 mm) Minimum permissible diameter (worn) ... 3.4985 in.(88.862 mm)Bore in main bearing ... 3.5030 .0010 in.(88.976 0.025 mm)Clearance between main bearing and crankshaft bearing surface (journal) ... .0015 to .0045 in.(0.038 to 0.114 mm)Maximum permissible clearance between main bearing and crankshaft bearing surface (journal) ... .006 in.(0.15 mm)Maximum permissible run out (axial eccentricity) of the crankshaft, measured at the center bearing surface (journal): 4.1 in. (104.1 mm) stroke engine ... .006 in.(0.15 mm)4.5 in. (114.3 mm) stroke engine ... .007 in.(0.18 mm)5.0 in. (127.0 mm) stroke engine ... .008 in.(0.20 mm)

Before installing gear, get temperature of gear to a maximum of 300° F (149° C)(1) End play for the crankshaft ... .006 .003 in.(0.15 0.08 mm) Maximum permissible end play for the crankshaft (worn) ... .012 in.(0.30 mm)(2) Diameter of bearing surfaces (journals) for the connecting rods ... 2.7500 .0004 in.(69.850 0.010 mm) Minimum permissible diameter (worn) ... 2.7486 in.(69.814 mm)(3) Diameter of bearing surfaces (journals) for main bearings ... 3.5000 .0005 in.(88.900 0.013 mm) Minimum permissible diameter (worn) ... 3.4985 in.(88.862 mm)Bore in main bearing ... 3.5030 .0010 in.(88.976 0.025 mm)Clearance between main bearing and crankshaft bearing surface (journal) ... .0015 to .0045 in.(0.038 to 0.114 mm)Maximum permissible clearance between main bearing and crankshaft bearing surface (journal) ... .006 in.(0.15 mm)Maximum permissible run out (axial eccentricity) of the crankshaft, measured at the center bearing surface (journal): 4.1 in. (104.1 mm) stroke engine ... .006 in.(0.15 mm)4.5 in. (114.3 mm) stroke engine ... .007 in.(0.18 mm)5.0 in. (127.0 mm) stroke engine ... .008 in.(0.20 mm)