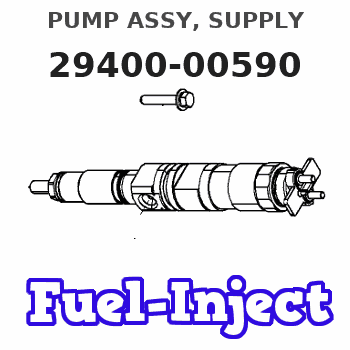

Information pump assy, supply

PUMP ASSY, SUPPLY

DA

- *1 REFER TO SERVICE BULLETIN DOCID 00400687E.

- (VIA THE "REPAIR INFO " MENU)

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Diesel Injector Pump 294000-0590 294000-1952 22100-E0060 22100-E0061 22100-E0062 Compatible For HINO N04C Truck 300 Fuel Injection Pump

BKAYOLOF Extend engine life: Good combustion effect and stable operation, reduce the internal carbon accumulation and wear of the engine, thus extending the service life of the engine. || Compact structure: high-pressure fuel pumps have a compact design, small size, light weight, easy to install in the engine compartment, saving space. || Strong self-priming ability: with self-priming characteristics, no external water absorption can be operated, even in the presence of air or gas in the fuel system, it can work normally. || Adapt to different working conditions: in various operating states of the engine, such as acceleration, deceleration, climbing, etc., can maintain a stable fuel supply, so that the engine is always in the best working state, and further optimize fuel consumption. || Diesel Injector Pump 294000-0590 294000-1952 22100-E0060 22100-E0061 22100-E0062 Compatible For HINO N04C Truck 300 Fuel Injection Pump

BKAYOLOF Extend engine life: Good combustion effect and stable operation, reduce the internal carbon accumulation and wear of the engine, thus extending the service life of the engine. || Compact structure: high-pressure fuel pumps have a compact design, small size, light weight, easy to install in the engine compartment, saving space. || Strong self-priming ability: with self-priming characteristics, no external water absorption can be operated, even in the presence of air or gas in the fuel system, it can work normally. || Adapt to different working conditions: in various operating states of the engine, such as acceleration, deceleration, climbing, etc., can maintain a stable fuel supply, so that the engine is always in the best working state, and further optimize fuel consumption. || Diesel Injector Pump 294000-0590 294000-1952 22100-E0060 22100-E0061 22100-E0062 Compatible For HINO N04C Truck 300 Fuel Injection Pump

Fuel Injection Pump 294000-0590 22100-E0060 Compatible with Hino Engine N04C Truck 300

Starhycfa Product name:Fuel Injection Pump || Part Number:294000-0590 22100-E0060 || APPlication:Compatible with Hino Engine N04C Truck 300 || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

Starhycfa Product name:Fuel Injection Pump || Part Number:294000-0590 22100-E0060 || APPlication:Compatible with Hino Engine N04C Truck 300 || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

Original Diesel Fuel Pump 294000-0590 Common Rail Injection Pump 22100-E0060 294000-0591 22100-E0061 Compatible With HINO

SYOTOE Stable fuel supply: it can continuously deliver fuel from the fuel tank to the engine to ensure that there will be no fuel shortage when the engine is running, so that the engine can run smoothly. || Adjustable pressure: it can provide fuel with appropriate pressure according to the requirements of different working conditions of the engine to ensure the fuel injection effect and the normal operation of the engine. || Sufficient flow rate: the oil transportation capacity per unit time is large, which can meet the fuel demand under the rated power condition of the engine, and can provide enough fuel even under high load or acceleration. || Quick response: the electric fuel pump can respond quickly according to the control signal of ECU, and realize the accurate control of fuel supply, so that the engine can get the required fuel in time under various working conditions. || Strong adaptability: there are many designs and configurations, which can adapt to different vehicle types and fuel system requirements, such as being installed inside or outside the fuel tank.

SYOTOE Stable fuel supply: it can continuously deliver fuel from the fuel tank to the engine to ensure that there will be no fuel shortage when the engine is running, so that the engine can run smoothly. || Adjustable pressure: it can provide fuel with appropriate pressure according to the requirements of different working conditions of the engine to ensure the fuel injection effect and the normal operation of the engine. || Sufficient flow rate: the oil transportation capacity per unit time is large, which can meet the fuel demand under the rated power condition of the engine, and can provide enough fuel even under high load or acceleration. || Quick response: the electric fuel pump can respond quickly according to the control signal of ECU, and realize the accurate control of fuel supply, so that the engine can get the required fuel in time under various working conditions. || Strong adaptability: there are many designs and configurations, which can adapt to different vehicle types and fuel system requirements, such as being installed inside or outside the fuel tank.

You can express buy:

USD 858

18-06-2018

18-06-2018

Genuine HP3 common rail fuel pump 294000-0590, 294000-0591, 294000-1950, 294000-1591, 294000-1592 for HINO N04C 22100-E0060

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 001. | PUMP ASSY, SUPPLY | 29400-00590 |

| 002. | OVERHAUL KIT, SUPP | 29400-90031 |

| 002. | OVERHAUL KIT, SUPP | 29400-90031 |

| 003. | OVERHAUL KIT, SUPP | 29400-90570 |

| 003. | OVERHAUL KIT, SUPP | 29400-90570 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00590 | 22100-E006 | PUMP ASSY, SUPPLY | |

| 22100-E0067 | HINO | PUMP ASSY, SUPPLY | |

| 22100-E0066 | HINO | PUMP ASSY, SUPPLY | |

| 22100-E0065 | HINO | PUMP ASSY, SUPPLY | |

| 22100-E0064 | HINO | PUMP ASSY, SUPPLY | |

| 22100-E0063 | HINO | PUMP ASSY, SUPPLY | |

| 22100-E0062 | HINO | PUMP ASSY SUPPLY | |

| 22100-E0061 | HINO | PUMP ASSY SUPPLY | |

| 22100-E0060 | HINO | PUMP ASSY SUPPLY | |

| 22100-78237 | TOYOTA | PUMP ASSY, SUPPLY | |

| 22100-78236 | TOYOTA | PUMP ASSY, SUPPLY | |

| 22100-78235 | TOYOTA | PUMP ASSY, SUPPLY | |

| 22100-78234 | TOYOTA | PUMP ASSY, SUPPLY | |

| 22100-78233 | TOYOTA | PUMP ASSY, SUPPLY | |

| 22100-78232 | TOYOTA | PUMP ASSY, SUPPLY | |

| 22100-78231 | TOYOTA | PUMP ASSY, SUPPLY | |

| 22100-78230 | TOYOTA | PUMP ASSY SUPPLY |

Information:

start by: a) remove oil pump1. Check the connecting rods and caps for their identification and location.2. Turn crankshaft until connecting rod caps are in position shown. 3. Remove the nuts (1) and the cap from connecting rod. Remove lower half of bearing from cap.4. Push the connecting rod away from the crankshaft. Remove the upper half of bearing from connecting rod. Install the bearings dry when the clearance checks are made. Put clean engine oil on the bearings for final assembly.5. Install upper half of bearing in connecting rod.6. Pull the connecting rod slowly on to the crankshaft.7. Install lower half of bearing in cap. Be sure the tabs in back of bearings are in the tab grooves of connecting rod and cap.

Do not use an impact wrench to tighten the bolts the additional 120° 5°.

8. Use Plastigage (A) to check bearing clearance.9. Put Plastigage (A) on the bearing.10. Put clean engine oil on threads of rod bolts and seat surfaces of nuts. Be sure the cylinder numbers on the rod cap and rod are the same and are on the same side of the connecting rod. Numbers are on the same side of rod and caps as are the grooves for the bearing tabs. If new rods are installed, put the cylinder number on the rod and cap. Do not turn the crankshaft when Plastigage (A) is in position. 11. Install the rod caps (2). Install the nuts. Tighten each nut to a torque of 60 6 lb. ft. (80 8 N m). Put a mark on the nuts and cap and tighten nuts an extra 120° 5° from the mark. Remove the rod cap. Remove Plastigage (A) and check the bearing clearance. The bearing clearance must be .0028 to .0066 in. (0.071 to 0.168 mm) for new bearings. Maximum clearance with used bearings is .010 in. (0.25 mm).12. Put clean engine oil on lower half of bearing. Install rod cap again. Tighten each nut to 60 6 lb.ft. (80 8 N m). Put a mark on nuts and cap and tighten nuts an extra 120° 5° from mark.13. Do Steps 1 through 12 for remainder of connecting rod bearings.end by:a) install oil pump

Do not use an impact wrench to tighten the bolts the additional 120° 5°.

8. Use Plastigage (A) to check bearing clearance.9. Put Plastigage (A) on the bearing.10. Put clean engine oil on threads of rod bolts and seat surfaces of nuts. Be sure the cylinder numbers on the rod cap and rod are the same and are on the same side of the connecting rod. Numbers are on the same side of rod and caps as are the grooves for the bearing tabs. If new rods are installed, put the cylinder number on the rod and cap. Do not turn the crankshaft when Plastigage (A) is in position. 11. Install the rod caps (2). Install the nuts. Tighten each nut to a torque of 60 6 lb. ft. (80 8 N m). Put a mark on the nuts and cap and tighten nuts an extra 120° 5° from the mark. Remove the rod cap. Remove Plastigage (A) and check the bearing clearance. The bearing clearance must be .0028 to .0066 in. (0.071 to 0.168 mm) for new bearings. Maximum clearance with used bearings is .010 in. (0.25 mm).12. Put clean engine oil on lower half of bearing. Install rod cap again. Tighten each nut to 60 6 lb.ft. (80 8 N m). Put a mark on nuts and cap and tighten nuts an extra 120° 5° from mark.13. Do Steps 1 through 12 for remainder of connecting rod bearings.end by:a) install oil pump