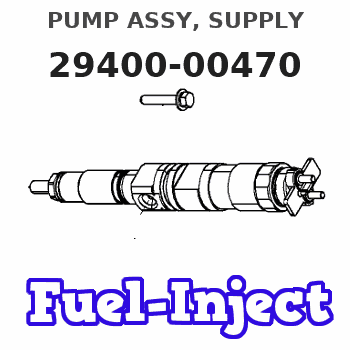

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Aftermarket Fuel injection Pump 294000-0470 16700-ES60 Fit Intended For n Engine YD22DDTi YD22DDT YD22ETI

Generic Motorcycle Parts || Heavy Equipment Parts || Spare Parts || Fuel Systems

Generic Motorcycle Parts || Heavy Equipment Parts || Spare Parts || Fuel Systems

Fuel injection pump Fits for Nissian YD22 Engine DDTi X-TRAIL ALMERA II 16700-ES60 294000-0470

KoovDem Part Number: 16700-ES60 294000-0470 16700ES60 2940000470 || Product Name: 16700-ES60 294000-0470 16700ES60 2940000470 Fuel injection pump || Brand new and unused items in pristine condition, unopened and in original packaging. Perfect for gifting or personal use. Guaranteed to meet expectations. Own something untouched and perfect today. || Designed specifically for Nissian YD22 engines, the DDTi X-TRAIL ALMERA II offers reliable and high-performance engine components. Whether for repairs or upgrades, this product exceeds expectations with top-quality materials and precision engineering. Trust in its exceptional results for years of smooth vehicle operations. || Please ensure that the product model you intend to purchase matches our specifications before proceeding with your order. If you are uncertain, feel free to reach out to us for clarification. Thank you for your cooperation in avoiding unnecessary returns.

KoovDem Part Number: 16700-ES60 294000-0470 16700ES60 2940000470 || Product Name: 16700-ES60 294000-0470 16700ES60 2940000470 Fuel injection pump || Brand new and unused items in pristine condition, unopened and in original packaging. Perfect for gifting or personal use. Guaranteed to meet expectations. Own something untouched and perfect today. || Designed specifically for Nissian YD22 engines, the DDTi X-TRAIL ALMERA II offers reliable and high-performance engine components. Whether for repairs or upgrades, this product exceeds expectations with top-quality materials and precision engineering. Trust in its exceptional results for years of smooth vehicle operations. || Please ensure that the product model you intend to purchase matches our specifications before proceeding with your order. If you are uncertain, feel free to reach out to us for clarification. Thank you for your cooperation in avoiding unnecessary returns.

IMIFAFTAbT 294000-0120 294000-0160 294000-0470 294000-0475 Fuel injection pump Fits for Nissan YD22DDTI YD22ETI Engine 2.2 DCI Primera Almera Tino X-Trail

IMIFAFTAbT Product Name: 294000-0120 294000-0160 294000-0470 294000-0475 Fuel injection pump || Part number: 294000-0120 294000-0160 294000-0470 294000-0475 || Fits for Nissan YD22DDTI YD22ETI Engine 2.2 DCI Primera Almera Tino X-Trail || 1 PCS Fuel injection pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

IMIFAFTAbT Product Name: 294000-0120 294000-0160 294000-0470 294000-0475 Fuel injection pump || Part number: 294000-0120 294000-0160 294000-0470 294000-0475 || Fits for Nissan YD22DDTI YD22ETI Engine 2.2 DCI Primera Almera Tino X-Trail || 1 PCS Fuel injection pump || Note: Please confirm that the product shown in the part number is what you need. If you cannot confirm you can leave us a message and provide your engine serial number and nameplate

You can express buy:

USD 358.06

07-05-2025

07-05-2025

Remanufactured HP3 294000-0470 Common Rail Fuel Pump 294000-0470 for Diesel Rail Fuel Engine

Images:

USD 485.45

[10-May-2025]

USD 60

[16-May-2019]

USD 66

[10-Nov-2022]

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-00470 |

| 001. | PUMP ASSY, SUPPLY | 29400-00470 |

| 001. | PUMP ASSY, SUPPLY | 29400-00470 |

| 001. | PUMP ASSY, SUPPLY | 29400-00470 |

| 001. | PUMP ASSY, SUPPLY | 29400-00470 |

| 001. | PUMP ASSY, SUPPLY | 29400-00470 |

| 002. | OVERHAUL KIT, SUPP | 29400-90031 |

Include in #3:

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00470 | 16700ES60A | PUMP ASSY, SUPPLY | |

| 16700ES61B | NISSAN MOTOR | PUMP ASSY, SUPPLY | |

| 16700ES61A | NISSAN MOTOR | PUMP ASSY, SUPPLY | |

| 16700ES60E | NISSAN MOTOR | PUMP ASSY, SUPPLY | |

| 16700ES60D | NISSAN MOTOR | PUMP ASSY, SUPPLY | |

| 16700ES60B | NISSAN MOTOR | PUMP ASSY, SUPPLY | |

| 16700ES60A | NISSAN MOTOR | PUMP ASSY SUPPLY |

Information:

1. Turn the crankshaft until the access holes in gears (1), (2) and (3) are in alignment with the nuts or bolts that hold the thrust washers to the timing gear plate. Turn the crankshaft more than one time if necessary to remove all of the nuts and bolts from the thrust washers. Do not remove any of the gears at this time.2. Turn the crankshaft to top center of compression stroke for No.1 piston. See LOCATING TOP CENTER FOR NO.1 PISTON in TESTING AND ADJUSTING.3. Install a 3/8"-16 NC eyebolt in drive shaft (6) and remove it from camshaft drive gear.

Do not turn crankshaft after drive shaft (6) or any of the gears are removed or damage to the pistons and valves will be the result.

4. Remove bolts (4), locks (5) and the hub from gear (7). 5. Remove the bolts, lock and washer to remove air compressor drive gear (8) from the timing gear plate. 6. Use tooling (A) and a press to remove the bearing from gear (8) as shown. 7. Remove gears (1), (2) and (3) and the thrust washers from the timing gear plate. 8. Use tooling (A) and a press to remove the bearings from gears (1), (2) and (3) as shown. 9. Turn gear (7) to make an alignment of the access holes in the gear with bolts (9). Remove the bolts, gear (7) and thrust washer from the timing gear plate. 10. Use tooling (A) and a press to remove the bearing from gear (7) as shown.Install Timing Gears

1. Use tooling (A) and a press to install the bearing in gear (1), until the bearing is even with the surface of the gear. 2. Install gear (1) and thrust washer (2) on the timing gear plate and tighten the bolts and locks to hold the thrust washer. 3. Use tooling (A) and a press to install the bearing in gear (3), until the bearing is even with the surface of the gear. 4. Use tooling (A) and a press to install the bearing in gear (4), until the bearing is even with the top surface of the gear as shown. 5. Put the bearing in position in compressor drive gear (5). Make sure that the reliefs in the bearing are in alignment with the reliefs in the gear. Use tooling (A) and a press to install the bearing even with the surface of gear (5) as shown. 6. Install the bearing in gear (6) with tooling (A) and a press until it is even with the surface of the gear.7. Make an alignment of the "V" mark on gear (3) with the "V" mark on the crankshaft gear and install gear (3) and the thrust washer on the timing gear plate.

Do not turn crankshaft after drive shaft (6) or any of the gears are removed or damage to the pistons and valves will be the result.

4. Remove bolts (4), locks (5) and the hub from gear (7). 5. Remove the bolts, lock and washer to remove air compressor drive gear (8) from the timing gear plate. 6. Use tooling (A) and a press to remove the bearing from gear (8) as shown. 7. Remove gears (1), (2) and (3) and the thrust washers from the timing gear plate. 8. Use tooling (A) and a press to remove the bearings from gears (1), (2) and (3) as shown. 9. Turn gear (7) to make an alignment of the access holes in the gear with bolts (9). Remove the bolts, gear (7) and thrust washer from the timing gear plate. 10. Use tooling (A) and a press to remove the bearing from gear (7) as shown.Install Timing Gears

1. Use tooling (A) and a press to install the bearing in gear (1), until the bearing is even with the surface of the gear. 2. Install gear (1) and thrust washer (2) on the timing gear plate and tighten the bolts and locks to hold the thrust washer. 3. Use tooling (A) and a press to install the bearing in gear (3), until the bearing is even with the surface of the gear. 4. Use tooling (A) and a press to install the bearing in gear (4), until the bearing is even with the top surface of the gear as shown. 5. Put the bearing in position in compressor drive gear (5). Make sure that the reliefs in the bearing are in alignment with the reliefs in the gear. Use tooling (A) and a press to install the bearing even with the surface of gear (5) as shown. 6. Install the bearing in gear (6) with tooling (A) and a press until it is even with the surface of the gear.7. Make an alignment of the "V" mark on gear (3) with the "V" mark on the crankshaft gear and install gear (3) and the thrust washer on the timing gear plate.