Information pump assy, supply

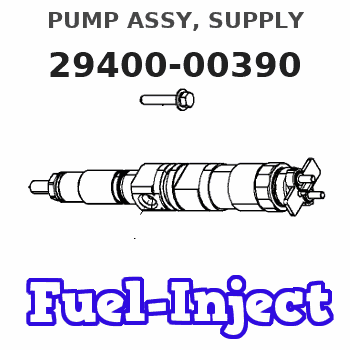

PUMP ASSY, SUPPLY

NB

- *1 294000-056# CAN BE USED INSTEAD OF 294000-039#

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

SPAKYGIE RE522595 Fuel Injection Pump fits for John Deere Loader 310K 310L 310SK 310SL 315SK 315SL 344J 524K 544K 624J 624K 644J 644K

SPAKYGIE ✅Part number:RE522595, RE546123, SE501916, 294000-039, 294000039, 294000-0390, 2940000390. || ✅This item fits for John Deere Engine 6068T 4045T. || ✅This item fits for John Deere Excavator:120D, 130G, 210G, 210GLC, 2144G, 2154G, 2154GLC, 250GLC, E210, E210LC, E230, E230LC, E240, E240LC, E260LC, E300LC. || ✅This item fits for John Deere Tractor:2044M, 2204, 6130, 6225, 6230, 6330, 6430, 6534, 6830, 6930, 7130, 7330, 7430, 7530, 7630, 7720, 7730, 7820, 7830, 7920, 7930, 6105M, 6110M. || ✅We could provide a variety of engine parts for 6068T 4045T.If you need other parts, please feel free to contact us.

SPAKYGIE ✅Part number:RE522595, RE546123, SE501916, 294000-039, 294000039, 294000-0390, 2940000390. || ✅This item fits for John Deere Engine 6068T 4045T. || ✅This item fits for John Deere Excavator:120D, 130G, 210G, 210GLC, 2144G, 2154G, 2154GLC, 250GLC, E210, E210LC, E230, E230LC, E240, E240LC, E260LC, E300LC. || ✅This item fits for John Deere Tractor:2044M, 2204, 6130, 6225, 6230, 6330, 6430, 6534, 6830, 6930, 7130, 7330, 7430, 7530, 7630, 7720, 7730, 7820, 7830, 7920, 7930, 6105M, 6110M. || ✅We could provide a variety of engine parts for 6068T 4045T.If you need other parts, please feel free to contact us.

Diesel Fuel Injection Oil Pump Diesel Fuel Feed Pump RE522595 294000-0390

VXRWKZEO Diesel Fuel Injection Oil Pump Diesel Fuel Feed Pump RE522595 294000-0390 || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

VXRWKZEO Diesel Fuel Injection Oil Pump Diesel Fuel Feed Pump RE522595 294000-0390 || Convenient installation: the design meets the standard specifications, and the installation process is simple, without complicated tools and professional skills. || Accurate fuel supply: adopt advanced technology, accurately control fuel injection quantity, ensure fuel to burn fully, improve fuel economy and reduce fuel consumption. || High efficiency and stability: strong power and stable injection, which can quickly respond to engine requirements and effectively improve the dynamic performance and driving experience of the car. || High quality and durability: made of high-quality materials, through rigorous testing, it is wear-resistant and durable, can adapt to various complex working conditions and has a long service life.

RE507959 294000-0059 6045 Engine Fuel Injection Pump For RE527528 SE501916 SE501915 294000-0390

Gvgsgtyu RE507959 294000-0059 6045 RE527528 SE501916 SE501915 294000-0390 || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

Gvgsgtyu RE507959 294000-0059 6045 RE527528 SE501916 SE501915 294000-0390 || Easy installation: No complex debugging process required, users can use it directly, greatly saving installation time and labor costs. || Easy to maintain: The product design emphasizes practicality, easy disassembly and cleaning, effectively reducing maintenance costs and time. || Reduce vibration: During the operation of the fuel pump, it can effectively reduce vibration transmission, ensure smooth operation of the equipment, and reduce noise and wear. || Long lifespan: Through advanced manufacturing processes and high-quality materials, the service life of fuel pumps has been effectively extended, improving the overall integrity of the equipment.

You can express buy:

USD 393.4

19-05-2025

19-05-2025

High-Quality Diesel Fuel Injection oil pump diesel fuel feed pump RE522595 294000-0390

USD 508

19-05-2025

19-05-2025

RE507959 294000-0059 Fuel Injection Pump for John Deere 6045 4045 Engine Excavator DENSO RE527528 SE501916 SE501915 294000-0390

Images:

USD 781.32

[05-May-2025]

USD 391.16

[19-May-2025]

USD 494.44

[20-Jun-2023]

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-00390 |

Scheme ###:

| 000. | [01] | 29400-00390 | PUMP ASSY, SUPPLY | RE522595 |

| 001. | [01] | 29410-00530 | HOUSING SUB-ASSY, | |

| 002. | [02] | 29417-80040 | WASHER, CAMSHAFT | |

| 003. | [01] | 29419-10010 | CAMSHAFT, SUPPLY P | |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-00010 | RING SUB-ASSY, CAM | |

| 006. | [01] | 29412-00270 | COVER SUB-ASSY, BE | |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90110 | BOLT, SOCKET | |

| 008. | [01] | 29419-80050 | O-RING, SUPPLY PUM | |

| 009. | [02] | 29419-80030 | O-RING, SUPPLY PUM | |

| 010. | [01] | 29418-30160 | PLATE, FEED PUMP, | |

| 011. | [01] | 29418-40080 | COVER, FEED PUMP | |

| 012. | [01] | 29418-70010 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00080 | ROTOR SET, FEED PU | |

| 014. | [05] | 09644-90050 | BOLT, SOCKET | |

| 015. | [01] | 29409-00040 | ELEMENT KIT, SUPPL | |

| 016. | [01] | 29409-00010 | ELEMENT KIT, SUPPL | |

| 017. | [02] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [02] | 29419-80010 | O-RING, SUPPLY PUM | |

| 019. | [02] | 29419-80040 | O-RING, SUPPLY PUM | |

| 020. | [06] | 29419-90010 | BOLT, SOCKET | |

| 031. | [01] | 09806-60030 | O-RING, DISTRIBUTI | |

| 032. | [01] | 17973-00020 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00100 | VALVE ASSY, SUCTIO | |

| 033. | [01] | 29420-00160 | VALVE ASSY, SUCTIO | |

| 033-001. | [01] | 29428-60010 | O-RING, VALVE | |

| 034. | [01] | 29428-50040 | O-RING, SOLENOID | |

| 035. | [01] | 29416-00011 | VALVE SUB-ASSY, RE | |

| 035-001. | [01] | 29419-80060 | O-RING, SUPPLY PUM | |

| 035-002. | [01] | 29419-80070 | O-RING, SUPPLY PUM | |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 29411-50010 | PLUG, FILTER | |

| 039. | [01] | 29411-70010 | GASKET, PLUG | |

| 040. | [01] | 09737-00010 | FILTER SUB-ASSY | |

| 041. | [01] | 09604-90460 | O-RING | |

| 043. | [01] | 29425-90020 | GASKET, SOLENOID | |

| 052. | [02] | 09001-40160 | CAP, VALVE HOLDER | |

| 053. | [01] | 09003-45220 | PLUG | |

| 054. | [01] | 09003-45230 | PLUG | |

| 101. | [01] | 29400-90010 | OVERHAUL KIT, SUPP | RE516999 |

| 102. | [01] | 29400-90020 | OVERHAUL KIT, SUPP | |

| 200. | [01] | 29400-90031 | OVERHAUL KIT, SUPP |

Include in #3:

29400-00390

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00390 | RE522595 | PUMP ASSY, SUPPLY | |

| RE522595 | JOHN DEERE | PUMP ASSY, SUPPLY | |

| RE52259S | JOHN DEERE | PUMP ASSY SUPPLY |

Information:

start by:a) remove oil pump1. Turn the crankshaft until two pistons are at bottom center. Remove the connecting rod caps from the two connecting rods. Remove the lower half of the bearings from the caps.2. Push the connecting rods away from the crankshaft and remove the upper half of the bearings.3. Clean the bearing contact surfaces in the caps and rods. Install the upper halves of the bearings in the connecting rods. Put clean SAE 30 engine oil on the bearings and crankshaft journals. Put the connecting rods in position on the crankshaft.4. Install the lower halves of the new bearings in the caps. Put clean SAE 30 engine oil on the bearings and on the threads of all bolts. 5. Put Plastigage (A) on the bearing to check the bearing clearance. Put the caps in position on the connecting rods and install the nuts on the bolts. Tighten the nuts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the nuts and bolts, and turn the nuts 90° more from the marks as shown. 6. Remove the rod cap and measure the thickness of the Plastigage to find the bearing clearance. Clearance with new bearings must be .0030 to .0066 in. (0.076 to 0.168 mm). Maximum permissible clearance with used bearings is .010 in. (0.25 mm).7. Put clean oil on the lower halves of the bearings and on the threads of the bolts. Put the caps in position on the connecting rods and install the nuts on the bolts. Tighten both nuts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the nuts and bolts, and turn the nuts 90° more from the mark as shown.

Make sure the number on the side of the connecting rod is the same number and on the same side as the number on the cap.

8. Do the above steps again for the remainder of the connecting rod bearings.end by:a) install oil pump

Make sure the number on the side of the connecting rod is the same number and on the same side as the number on the cap.

8. Do the above steps again for the remainder of the connecting rod bearings.end by:a) install oil pump