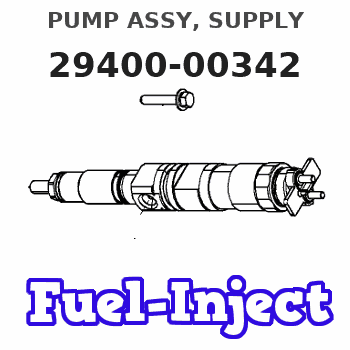

Information pump assy, supply

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump Compatible With Mitsubishi Diesel Engine 4M41 294000-0340 1460A003 2940000342 Excavator Engine Replacement Parts

YERCBX Enhance the engine's power output || Low-noise operation: Optimized internal structure and materials, resulting in low noise during operation || The key components have excellent wear resistance, extending the overall service life || Integrated design: Compact structure, small space occupation, and convenient for vehicle installation and layout. || Easy maintenance: The design is reasonable, and daily inspection and maintenance operations are simple, saving time

YERCBX Enhance the engine's power output || Low-noise operation: Optimized internal structure and materials, resulting in low noise during operation || The key components have excellent wear resistance, extending the overall service life || Integrated design: Compact structure, small space occupation, and convenient for vehicle installation and layout. || Easy maintenance: The design is reasonable, and daily inspection and maintenance operations are simple, saving time

Fuel Injection Pump Compatible with Mitsubishi Diesel Engine 4M41 294000-0340 1460A003 2940000342 Excavator Engine Replacement Parts

WSULQKOG 【Easy installation】automotive fuel injection pump design is reasonable, the installation method is simple and clear || 【Injection pressure】The engine fuel pump can produce a higher injection pressure, so that the fuel is better atomized, improve the engine power output || 【Stable operation】 The fuel injection pump can maintain stable fuel injection pressure under high load and harsh working conditions, and has a long service life || 【Reduced fuel consumption】 Fuel supply pumps reduce fuel waste and reduce vehicle operating costs by optimizing fuel injection contro || Fuel Injection Pump Compatible with Mitsubishi Diesel Engine 4M41 294000-0340 1460A003 2940000342 Excavator Engine Replacement Parts

WSULQKOG 【Easy installation】automotive fuel injection pump design is reasonable, the installation method is simple and clear || 【Injection pressure】The engine fuel pump can produce a higher injection pressure, so that the fuel is better atomized, improve the engine power output || 【Stable operation】 The fuel injection pump can maintain stable fuel injection pressure under high load and harsh working conditions, and has a long service life || 【Reduced fuel consumption】 Fuel supply pumps reduce fuel waste and reduce vehicle operating costs by optimizing fuel injection contro || Fuel Injection Pump Compatible with Mitsubishi Diesel Engine 4M41 294000-0340 1460A003 2940000342 Excavator Engine Replacement Parts

ZTUOAUMA HP3 Fuel Injection Pump 1460A003 294000-0340 Compatible with Mitsubishi 4M41 Di-D 3.2L Engine L200 Pajero Pickups

ZTUOAUMA Part Number: 294000-0340 1460A003 294000-0342 294000-0341 294000-0343 1460A044 || Application Models: Compatible with Mitsubishi 4M41 Di-D 3.2L Engine L200 Pajero Di-D 4WD V80 V90 Pickups || Direct Replacement; OEM Quality&Function; Easy Installation || All parts are strictly tested in factory to ensure the better function and durability

ZTUOAUMA Part Number: 294000-0340 1460A003 294000-0342 294000-0341 294000-0343 1460A044 || Application Models: Compatible with Mitsubishi 4M41 Di-D 3.2L Engine L200 Pajero Di-D 4WD V80 V90 Pickups || Direct Replacement; OEM Quality&Function; Easy Installation || All parts are strictly tested in factory to ensure the better function and durability

You can express buy:

Components :

| 001. | PUMP ASSY, SUPPLY | 29400-00342 |

| 001. | PUMP ASSY, SUPPLY | 29400-00342 |

| 002. | OVERHAUL KIT, SUPP | 29400-90080 |

Scheme ###:

| 000. | [01] | 29400-00342 | PUMP ASSY, SUPPLY | 1460A003 |

| 000. | [01] | 29400-00343 | PUMP ASSY, SUPPLY | 1460A044 |

| 001. | [01] | 29410-00421 | HOUSING SUB-ASSY, | SM |

| 002. | [02] | 29417-80060 | WASHER, CAMSHAFT | SM |

| 003. | [01] | 29419-10060 | CAMSHAFT, SUPPLY P | SM |

| 004. | [01] | 29402-10020 | KEY, WOODRUFF | |

| 005. | [01] | 29417-00260 | RING SUB-ASSY, CAM | SM |

| 005. | [01] | 29417-00150 | RING SUB-ASSY, CAM | SM |

| 005. | [01] | 29417-00080 | RING SUB-ASSY, CAM | SM |

| 006. | [01] | 29412-00130 | COVER SUB-ASSY, BE | SM |

| 006. | [01] | 29412-00290 | COVER SUB-ASSY, BE | SM |

| 006. | [01] | 29412-00330 | COVER SUB-ASSY, BE | SM |

| 006-001. | [01] | 29419-70010 | SEAL, OIL | |

| 007. | [06] | 09644-90380 | BOLT, SOCKET | SM |

| 008. | [01] | 29419-80120 | O-RING, SUPPLY PUM | SM |

| 009. | [02] | 29419-80100 | O-RING, SUPPLY PUM | SM |

| 010. | [01] | 29418-30200 | PLATE, FEED PUMP, | SM |

| 011. | [01] | 29418-40160 | COVER, FEED PUMP | SM |

| 012. | [01] | 29418-70030 | KEY, FEED PUMP | |

| 012. | [01] | 29418-70050 | KEY, FEED PUMP | |

| 013. | [01] | 29418-00100 | ROTOR SET, FEED PU | SM |

| 014. | [05] | 09644-90370 | BOLT, SOCKET | SM |

| 015. | [01] | 29409-00110 | ELEMENT KIT, SUPPL | SM |

| 015. | [01] | 29409-00530 | ELEMENT KIT, SUPPL | SM |

| 015. | [01] | 29409-01040 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-00100 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-00560 | ELEMENT KIT, SUPPL | SM |

| 016. | [01] | 29409-01050 | ELEMENT KIT, SUPPL | SM |

| 017. | [02] | 29415-90040 | SPRING, PLUNGER | |

| 018. | [02] | 29419-80080 | O-RING, SUPPLY PUM | SM |

| 019. | [02] | 29419-80110 | O-RING, SUPPLY PUM | SM |

| 020. | [06] | 29419-90030 | BOLT, SOCKET | SM |

| 031. | [01] | 29419-80150 | O-RING, SUPPLY PUM | SM |

| 032. | [01] | 17973-00100 | SENSOR, FUEL TEMPE | |

| 033. | [01] | 29420-00360 | VALVE ASSY, SUCTIO | SM |

| 033. | [01] | 29420-00160 | VALVE ASSY, SUCTIO | SM |

| 033-001. | [01] | 29428-60030 | O-RING, VALVE | SM |

| 034. | [01] | 29428-50030 | O-RING, SOLENOID | SM |

| 035. | [01] | 29416-00071 | VALVE SUB-ASSY, RE | SM |

| 035. | [01] | 29416-00120 | VALVE SUB-ASSY, RE | SM |

| 035. | [01] | 29416-00160 | VALVE SUB-ASSY, RE | SM |

| 035-001. | [01] | 29419-80130 | O-RING, SUPPLY PUM | SM |

| 035-002. | [01] | 29419-80140 | O-RING, SUPPLY PUM | SM |

| 036. | [01] | 29401-00120 | PIPE, SUPPLY PUMP | SM |

| 037. | [02] | 29416-90010 | PIN, STOPPER | |

| 038. | [01] | 29411-50031 | PLUG, FILTER | SM |

| 039. | [01] | 29411-70020 | GASKET, PLUG | SM |

| 040. | [01] | 09737-00050 | FILTER SUB-ASSY | SM |

| 041. | [01] | 29419-80160 | O-RING, SUPPLY PUM | SM |

| 043. | [01] | 29425-90020 | GASKET, SOLENOID | |

| 052. | [01] | 09001-45170 | CAP, VALVE HOLDER | SM |

| 053. | [01] | 09808-10100 | COVER, RUBBER | SM |

| 054. | [01] | 09808-10110 | COVER, RUBBER | SM |

| 101. | [01] | 29400-90010 | OVERHAUL KIT, SUPP | SM |

| 102. | [01] | 29400-90100 | OVERHAUL KIT, SUPP | SM |

| 200. | [01] | 29400-90080 | OVERHAUL KIT, SUPP | SM |

Include in #3:

29400-00342

as PUMP ASSY, SUPPLY

Cross reference number

| Part num | Firm num | Firm | Name |

| 29400-00342 | 1460A003 | PUMP ASSY, SUPPLY |

Information:

start by:a) remove pistons1. Remove the bearings from the connecting rod and connecting rod cap. 2. Remove retainer ring (1) with tool (C).3. Remove pin (2) and the connecting rod (4) from the piston (3). 4. Remove the piston rings from the piston with tool (A). Clean the piston ring grooves on the pistons with an acceptable ring groove cleaning tool. See USE OF PISTON PIN BEARING REMOVAL AND INSTALLATION TOOLS, SPECIAL INSTRUCTION, Form No. SMHS7295.5. Heat the connecting rod in an oven to a temperature of 350°-500°F (177°-260°C). Never use a direct flame to heat a connecting rod. 6. Put connecting rod (4) in position on the base plate of tooling (B). Put a new rod pin bearing (5) on the adapter part of tooling (B). Make sure that the joint in the rod pin bearing is 90° from a center line through the crankshaft and pin bearing bores. 7. Install the pusher adapter (7) and pusher (8) part of tooling (B) on the adapter. The old bearing is pushed out by tooling (B) as the new bearing is installed.8. Use tooling (B) to push the new bearing into the connecting rod until the push adapter of tooling (B) makes full contact with the connecting rod surface.9. Use a pin boring machine to make the rod pin bearing the correct size. The bore in the new rod pin bearing must be 2.0012 .0003 in. (50.830 0.008 mm).10. Check the clearance between the ends of the piston rings. See PISTONS AND RINGS in SPECIFICATIONS.11. Install the oil ring spring in the oil ring groove of the piston. The oil ring is to be installed over the spring with the oil ring end gap 180° from the oil ring spring joint. 12. Install the oil ring on the piston with tool (A).13. Install the second (intermediate) piston ring with the side that has the identification "UP-2" toward the top of the piston with tool (A).14. Install the first (top) piston ring with the side that has the identification "UP-1" toward the top of the piston with tool (A). After the installation of all three piston rings, put the piston ring in position so the end gaps are 120° apart. 15. Put piston (3) in position on connecting rod (4). Put clean engine oil on pin (2) and install the pin. Install retainer rings (1) with tool (C). Make sure the retainer rings are in the grooves of the piston.16. Install the bearings in the connecting rod and connecting rod cap.end by:a) install pistons