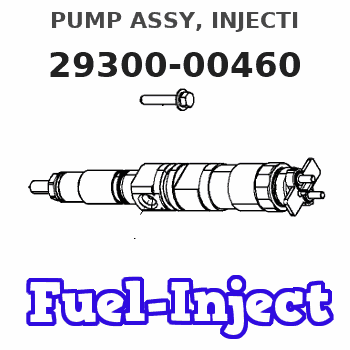

Information pump assy, injecti

Nozzle:

0935007210

Rating:

KIT List:

| Governor assy, mec | 1908900720 |

| Timer assy, automa | No Application |

| Pump assy, fuel fe | 1922900060 |

| Body assy, injecti | 1904400380 |

| Body assy, injecti | 1904400380 |

Components :

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 001. | PUMP ASSY, INJECTI | 29300-00460 |

| 002. | GOVERNOR ASSY, MEC | 09130-06651 |

| 002. | GOVERNOR ASSY, MEC | 09130-06651 |

| 003. | TIMER ASSY, AUTOMA | 09180-04080 |

| 003. | TIMER ASSY, AUTOMA | 09180-04080 |

| 004. | PUMP ASSY, FUEL FE | 09210-03340 |

| 004. | PUMP ASSY, FUEL FE | 09210-03340 |

| 005. | COUPLING ASSY | 09250-01061 |

| 005. | COUPLING ASSY | 09250-01061 |

| 006. | BODY ASSY, INJECTI | 19010-01421 |

| 006. | BODY ASSY, INJECTI | 19010-01421 |

| 007. | COVER, BEARING | 09020-10430 |

| 007. | COVER, BEARING | 09020-10430 |

| 008. | BODY ASSY, INJECTI | 19010-01630 |

| 008. | BODY ASSY, INJECTI | 19010-01630 |

Scheme ###:

| 000. | [01] | 29300-00464 | PUMP ASSY, INJECTI | 22010-78231-000 |

| 000. | [01] | 29300-00465 | PUMP ASSY, INJECTI | 22010-78231-000 |

| 000. | [01] | 29300-00466 | PUMP ASSY, INJECTI | 22010-78231-000 |

| 003. | [01] | 19010-01421 | BODY ASSY, INJECTI | |

| 003. | [01] | 19010-01632 | BODY ASSY, INJECTI | |

| 004. | [01] | 09130-06652 | GOVERNOR ASSY, MEC | 22410-78230-000 |

| 005. | [01] | 09180-04080 | TIMER ASSY, AUTOMA | |

| 006. | [01] | 09001-20340 | NUT, TIMER ROUND | 22611-5C350-000 |

| 007. | [01] | 09250-01061 | COUPLING ASSY | |

| 008. | [01] | 90458-05750 | KEY, WOODRUFF | 90097-00575-000 |

| 009. | [01] | 09210-03340 | PUMP ASSY, FUEL FE | |

| 012. | [01] | 94904-76900 | BOLT, W/WASHER | 90099-04483-000 |

| 013. | [04] | 94904-76890 | BOLT, W/WASHER | 90099-04482-000 |

| 014. | [01] | 94904-76910 | BOLT, W/WASHER | 90099-04484-000 |

| 015. | [02] | 94904-76880 | BOLT, W/WASHER | 90099-04481-000 |

| 019. | [01] | 09028-50030 | CAP | 22217-B3010-000 |

| 020. | [01] | 09028-50050 | CAP | 22217-B3020-000 |

| 021. | [01] | 09031-00450 | VALVE ASSY, OVERFL | 22199-78290-000 |

| 022. | [02] | 94901-02480 | WASHER | 90099-01501-000 |

| 023. | [02] | 91418-08351 | BOLT, W/WASHER | 91611-60835-000 |

| 024. | [01] | 09045-30210 | STAY, INJECTION PU | |

| 027. | [01] | 13650-01031 | SENSOR ASSY, POSIT | |

| 028. | [02] | 94904-63030 | BOLT | |

| 029. | [2C] | 94901-32310 | WASHER, PLATE, SK | |

| 029. | [2C] | 94901-35020 | WASHER, PLATE, SK | 90099-01540-000 |

| 029. | [2C] | 94901-35030 | WASHER, PLATE, SK | 90099-01541-000 |

| 030. | [01] | 94914-06680 | O-RING |

Cross reference number

| Part num | Firm num | Firm | Name |

| 29300-00460 | PUMP ASSY, INJECTI | ||

| 22010-8556 | HINO | PUMP ASSY, INJECTI | |

| 22010-8555 | HINO | PUMP ASSY, INJECTI | |

| 22010-8554 | HINO | PUMP ASSY, INJECTI | |

| 22010-8553 | HINO | PUMP ASSY, INJECTI | |

| 22010-78232 | TOYOTA | PUMP ASSY, INJECTI | |

| 22010-78231-000 | DAIHATSU | PUMP ASSY, INJECTI | |

| 22010-78231 | TOYOTA | PUMP ASSY, INJECTI | |

| 22010-78230 | TOYOTA | PUMP ASSY, INJECTI | |

| S2201-08556 | HINO | PUMP ASSY, INJECTI |

Information:

At operating temperature, the engine coolant is hot and under pressure.Steam can cause personal injury.Check the coolant level only after the engine has been stopped and the filler cap is cool enough to touch with your bare hand.Remove the filler cap slowly to relieve pressure.Cooling system conditioner contains alkali. Avoid contact with the skin and eyes to prevent personal injury.Use all cleaning solutions with care.

Never add coolant to an overheated engine, allow the engine to cool first.Check the specific gravity of the antifreeze solution frequently in cold weather to ensure adequate protection.If the machine is to be stored in or shipped to, an area with below freezing temperatures, the cooling system must be protected against freezing to the lowest expected ambient temperature.All water is corrosive at engine operating temperature. The cooling system should be protected with conditioner at all times regardless of the concentration of antifreeze. This can be done by using Caterpillar coolant conditioner elements. Use a precharge element when filling the system or changing coolant. Install a new maintenance element every 250 service hours during operation.

Do not use Caterpillar cooling conditioner elements with Dowtherm 209 Full-Fill coolant. Follow the instructions provided with the Dowtherm 209 Full-Fill coolant.Coolant should be drained and replaced every 2000 service hours or 1 year. However, when coolant conditioner maintenance elements are replaced every 250 service hours as recommended, the drain period can be extended to 4000 service hours or 2 years.Premix antifreeze solution to provide protection to the lowest expected ambient temperature. Pure undiluted antifreeze will freeze at -23°C (-10°F).Use clean water that is low in scale forming mineral. Do not use softened water.Filling at over 20 liters (5 U.S. gallons) per minute can cause air pockets in the cooling system.After draining and refilling the cooling system, run the engine with the filler cap off until the coolant level stabilizes. Add coolant as necessary to fill the system.The engine cooling system is protected to -28°C (-20°F), with permanent-type antifreeze, when shipped from the factory.Operate with a thermostat in the cooling system all year-round. The engine will overheat without a thermostat.Clean the Cooling System

The machine must be level with the bowl lowered, the parking brake applied and the engine stopped and cool. 1. Remove the radiator cap slowly to relieve the pressure. 2. Remove the access cover, located in the engine guard. 3. Remove the drain valve plug (1). Open the valve (2) and allow the coolant to drain.4. Close the drain valve.5. Fill the cooling system with a cleaning solution. Use a commercially available cleaner or 1 kg sodium bisulfate per 38 liters (2 lb per 10 gal) water.6. Start and operate the engine for 1/2hour. Stop the engine and drain the cleaning solution.7. Flush the system, with the engine stopped, with water until draining water is clear.8. Close the drain valve. Fill the system with a neutralizer. Use a commercially available neutralizer or 250 grams sodium carbonate crystals per 38 liters (1/2 lb to 10 gal) water.9. Operate the engine