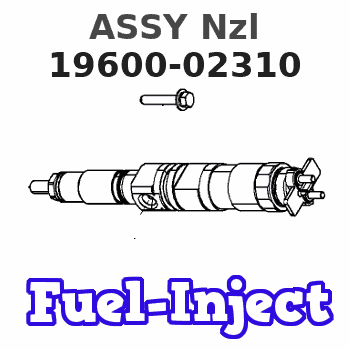

Information assy nzl

Nozzle:

0935006890

Rating:

KIT List:

| Pump assy, injecti | 0960100551 |

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

WZCNLXLX Fuel Injection Pump 22100-1C060 196000-2310 For Land Cruiser ZJ75 HZJ78 HZJ79 HZJ105 1HZ Engine

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:22100-1C060 196000-2310 221001C060 1960002310 || Application:For Land Cruiser ZJ75 HZJ78 HZJ79 HZJ105 1HZ Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

WZCNLXLX Item Name:Fuel Injection Pump || Item Number:22100-1C060 196000-2310 221001C060 1960002310 || Application:For Land Cruiser ZJ75 HZJ78 HZJ79 HZJ105 1HZ Engine || Note: If you are unsure if the product is suitable.In order not to delay your use of the parts, please provide your engine nameplate or serial number and part number, and we will help you confirm if it is suitable. To avoid unnecessary returns, please check the product image and part number to ensure it is the product you want. || Tip: Please contact us - we are a professional sales team and we have many products to offer to you. Many buyers are very satisfied with our service. You can get first-class products and high-quality services from us, believe me, you will have a pleasant shopping experience here.

You can express buy:

USD 412.58

19-05-2025

19-05-2025

China made new Fuel Injection Pump 196000-2310 22100-1C060 for Landcruiser 1HZ

Images:

USD 481.69

[19-May-2025]

USD 485.6

[13-May-2025]

USD 378.03

[19-May-2025]

USD 989.38

[19-May-2025]

Components :

| 001. | PUMP ASSY, INJECTI | 19600-02310 |

| 002. | BELLOWS ASSY, PNEU | 09071-00501 |

| 003. | BELLOWS ASSY, PNEU | 09071-00640 |

| 004. | BELLOWS ASSY, PNEU | 09071-00710 |

| 005. | RING SUB-ASSY, ROL | 09618-00030 |

| 006. | GOVERNOR ASSY, TOR | 09627-00890 |

| 007. | SHIM, PLUNGER ADJU | 09640-60020 |

Cross reference number

| Part num | Firm num | Firm | Name |

| 19600-02310 | ASSY Nzl | ||

| 22100-1C060 | TOYOTA | PUMP ASSY, INJECTI |

Information:

Scheduled Oil Sampling (S O S) Analysis

To compliment a good preventive maintenance program, Caterpillar recommends using S O S analysis at regular scheduled intervals to monitor the condition of the engine oil and maintenance requirements of your engine.Obtain Sample

Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase. There are two methods recommended to obtain S O S samples from the engine crankcase.

Oil Sampling Valve* Use the sampling valve.* Use a sampling gun inserted into the sump. Refer to How to Take a Good Oil Sample, PEHP6001 for a step-by-step explanation if using this method of sampling crankcase oil.Caterpillar recommends using one of the above methods. If either of these methods are not possible, then use a drain stream method when changing oil. When using the drain stream to obtain the oil sample, do not sample from the beginning or end of drain stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of the oil in the crankcase. Consult your Caterpillar dealer for complete information and assistance in establishing an S O S program for your engine.Oil Drain Intervals

The Maintenance Schedule assumes the use of SUPERIOR QUALITY API CG-4 (minimum) performance oil, which has sufficient TBN for fuels with less than 0.5 percent sulfur.Many conditions exist that can affect the selection of an optimum oil change period. The fundamental requirement in this decision must be to maintain the lube oil in an acceptable condition that provides continual engine protection. The quality and amount of oil available is balanced against oil ability to absorb combustion by-products. It is essential to include an S O S analysis of oil condition before oil change period adjustment is considered.All oils do not perform equally. A lower quality lube oil would require that the oil change intervals be reduced accordingly. If the sulfur content in the fuel is greater than 1.5 percent by weight, use an oil with a TBN of 30 and reduce oil change interval by one half the interval recommended in the Maintenance Schedule.If the engine crankcase oil has reached its condemning limits as established by the oil analysis program, refer to the topic, Engine Oil and Filter(s), in this publication for the procedure to change the crankcase oil and oil filters.Due to manufacturing tolerances, engine application and maintenance variation, all engines do not consume fuel and oil at the same rate. The amount of fuel consumed is in direct relation to the maximum oil change interval selected. Some history of fuel and oil consumed for each engine (or group of engines) in a similar application must be established.For a group of engines, average fuel consumption and add oil rate may be determined by multiplying the total quantity of fuel consumed by the operating (service) hours of the engines.For more information on adjusting or extending oil change intervals for specific applications, see

To compliment a good preventive maintenance program, Caterpillar recommends using S O S analysis at regular scheduled intervals to monitor the condition of the engine oil and maintenance requirements of your engine.Obtain Sample

Each oil sample should be taken when the oil is warm and well mixed to ensure that the sample is representative of the oil in the crankcase. There are two methods recommended to obtain S O S samples from the engine crankcase.

Oil Sampling Valve* Use the sampling valve.* Use a sampling gun inserted into the sump. Refer to How to Take a Good Oil Sample, PEHP6001 for a step-by-step explanation if using this method of sampling crankcase oil.Caterpillar recommends using one of the above methods. If either of these methods are not possible, then use a drain stream method when changing oil. When using the drain stream to obtain the oil sample, do not sample from the beginning or end of drain stream. The oil at the beginning or end of the drain stream is not mixed well enough to be representative of the oil in the crankcase. Consult your Caterpillar dealer for complete information and assistance in establishing an S O S program for your engine.Oil Drain Intervals

The Maintenance Schedule assumes the use of SUPERIOR QUALITY API CG-4 (minimum) performance oil, which has sufficient TBN for fuels with less than 0.5 percent sulfur.Many conditions exist that can affect the selection of an optimum oil change period. The fundamental requirement in this decision must be to maintain the lube oil in an acceptable condition that provides continual engine protection. The quality and amount of oil available is balanced against oil ability to absorb combustion by-products. It is essential to include an S O S analysis of oil condition before oil change period adjustment is considered.All oils do not perform equally. A lower quality lube oil would require that the oil change intervals be reduced accordingly. If the sulfur content in the fuel is greater than 1.5 percent by weight, use an oil with a TBN of 30 and reduce oil change interval by one half the interval recommended in the Maintenance Schedule.If the engine crankcase oil has reached its condemning limits as established by the oil analysis program, refer to the topic, Engine Oil and Filter(s), in this publication for the procedure to change the crankcase oil and oil filters.Due to manufacturing tolerances, engine application and maintenance variation, all engines do not consume fuel and oil at the same rate. The amount of fuel consumed is in direct relation to the maximum oil change interval selected. Some history of fuel and oil consumed for each engine (or group of engines) in a similar application must be established.For a group of engines, average fuel consumption and add oil rate may be determined by multiplying the total quantity of fuel consumed by the operating (service) hours of the engines.For more information on adjusting or extending oil change intervals for specific applications, see